In the highly competitive world of precision machining, standing out as a customized centerless grinder manufacturer requires not just advanced technology but also a profound understanding of customer needs and market dynamics. Industry leaders know that to succeed, they must offer unparalleled experience, expertise, authoritativeness, and trustworthiness—pillars that form the foundation of any reputable manufacturing enterprise.

Centerless grinding, a critical aspect of precision finishing, demands an intricate balance of machines operating seamlessly. Unlike conventional grinding machines, centerless grinders do not rely on centers to hold the workpiece. Instead, they achieve superior surface finish and dimensional accuracy by keeping the workpiece between two rotating wheels. For manufacturers of customized centerless grinders, this means tailoring complex machinery to meet the precise specifications of varied industries, ranging from aerospace to automotive, and medical devices to consumer electronics.

Experience is the cornerstone of any successful manufacturer. Handling the unique challenges of customization in centerless grinders requires years of accumulated knowledge and practical engagement with diverse industrial requirements. The ability to innovate while incorporating time-tested solutions is what sets experienced manufacturers apart. Their seasoned engineers not only have the skills to modify existing designs but also to foresee potential design challenges and mitigate them before they occur, thus reducing downtime and maintenance costs for the end-user.

In terms of expertise, a customized centerless grinder manufacturer must boast a team proficient in the latest advancements in CNC technology, metallurgy, and process optimization. This expertise is essential for developing machinery that can handle a wide range of materials, from soft plastics to hard ceramics, with high precision. Manufacturers who invest in continuous training and development of their workforce often lead the way in technological innovation, ensuring that their clients have access to the most cutting-edge grinding solutions available.

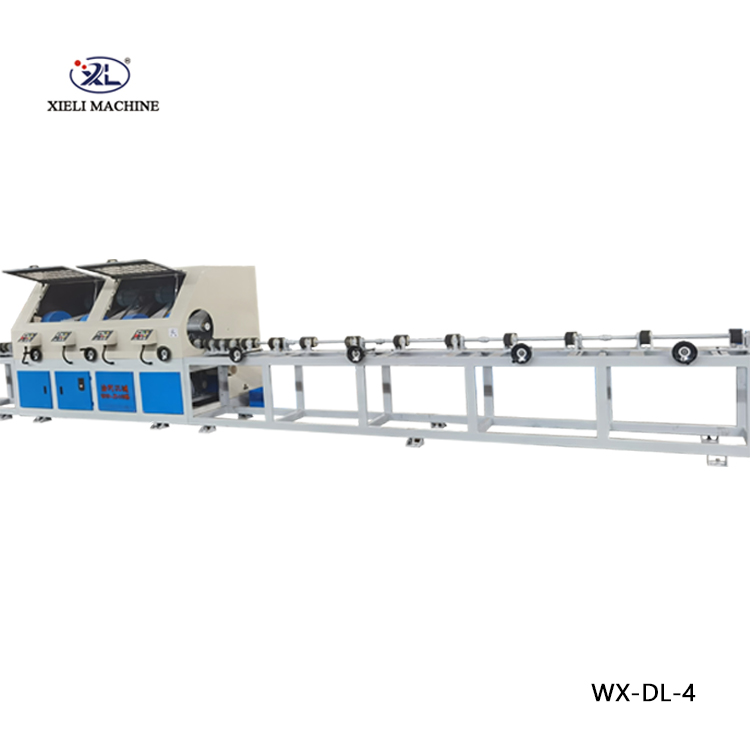

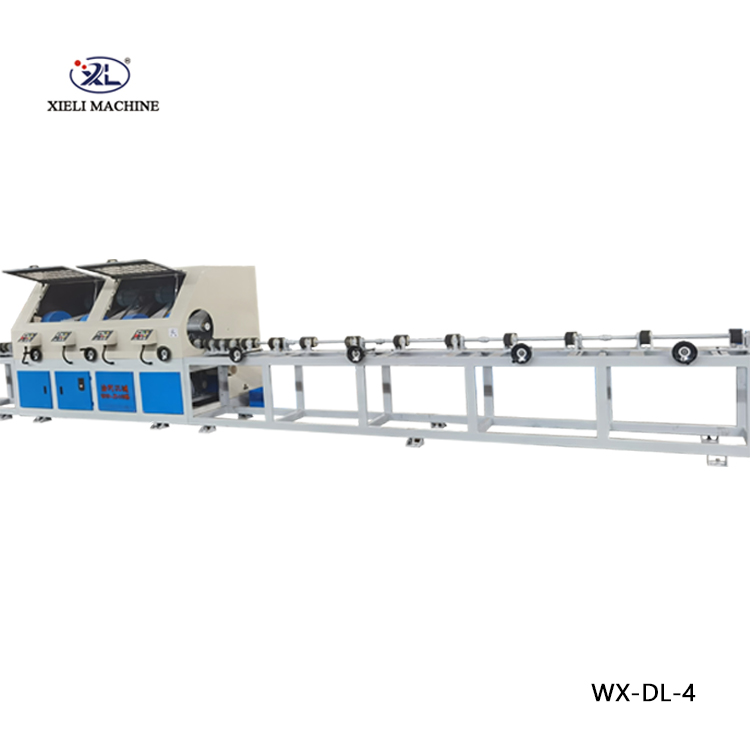

customized centerless grinder manufacturer

Authoritativeness is deeply rooted in a manufacturer’s ability to consistently deliver high-quality, robust machines that perform reliably under demanding conditions. It is often reflected in industry certifications and compliance with international standards, which not only cement the manufacturer's position as a leader in the field but also provide customers with the assurance that the products they receive conform to the highest benchmarks of quality and safety.

Trustworthiness, intrinsically linked to customer relationships, is arguably the most crucial of these pillars. A manufacturer that promises and delivers exceptional after-sales service, including prompt technical support, readily available spare parts, and comprehensive training programs, earns their clients' trust. Moreover, offering warranties and guarantees speaks volumes about the manufacturer’s confidence in their product, which in turn reinforces customer faith.

The synergy between these four elements—experience, expertise, authoritativeness, and trustworthiness—not only elevates a customized centerless grinder manufacturer above their competitors but also ensures long-term success and sustainability. By focusing on these aspects, a manufacturer can create a robust, trust-based network of returning customers who value their products not just for their precision and reliability but for the comprehensive support and partnership that comes with them.

Ultimately, for those who seek the pinnacle of precision engineering, a manufacturer who embodies these principles inherently becomes a preferred choice. They provide not only machines but also solutions tailored to the evolving needs of industries that demand nothing less than excellence. As industries continue to evolve, so too must the partners they rely on; those that fail to innovate and maintain these key qualities may quickly find themselves left behind in an ever-progressing landscape.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.