Customized Centerless Grinder Exporter Paving the Way for Precision Manufacturing

In today's fast-paced manufacturing landscape, the need for precision and efficiency is paramount. This demand has given rise to specialized machinery that can deliver exceptional results. Among these, the customized centerless grinder has emerged as a crucial player, especially in industries such as automotive, aerospace, and medical manufacturing. As more companies seek to enhance their operational efficiency, the role of customized centerless grinder exporters has become increasingly significant.

Understanding Centerless Grinding Technology

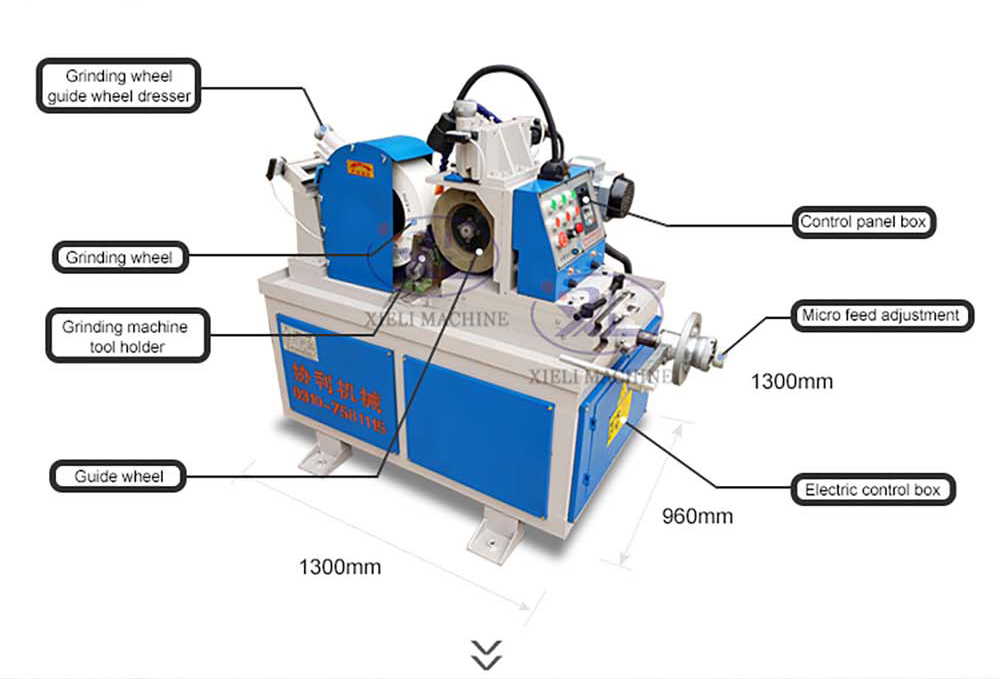

Centerless grinding is a manufacturing process that involves the grinding of the outer surfaces of an object without the need for a spindle or fixture. This technique allows for high-precision machining of cylindrical parts, making it ideal for applications where tight tolerances are required. The process generally uses three main components the grinding wheel, the regulating wheel, and the workpiece, which is held in place by the wheels without any central support.

The advantage of this method lies in its ability to process long batches of materials efficiently. Centerless grinders can produce parts with superior roundness, linearity, and surface finishes, making them indispensable in high-volume production environments.

Tailored Solutions for Diverse Industries

One of the defining features of centerless grinders is their adaptability. Every industry has unique requirements for size, shape, and material composition. Customized centerless grinder exporters focus on providing tailored solutions to meet these specific needs. By working closely with clients, they can design and manufacture machines that integrate seamlessly into existing production lines, thereby enhancing overall productivity.

For instance, the automotive industry requires precision ground components such as shafts, pins, and bushings

. A customized centerless grinder can be designed to accommodate the specific dimensions and tolerances required for these parts, ensuring consistency and quality in production.Similarly, in the medical sector, where the quality of components is directly linked to patient safety, customized grinders can produce intricate parts with exceptional accuracy. This includes items like surgical instruments or implant components, where even the slightest deviation can have serious consequences.

customized centerless grinder exporter

The Role of Exporters in the Global Market

With the rise of globalization, the demand for advanced manufacturing equipment has reached beyond domestic borders. Customized centerless grinder exporters play a pivotal role in meeting this demand. These exporters not only deliver machinery to various parts of the world but also provide support services such as installation, training, and maintenance.

By understanding the regulatory standards and operational challenges in different countries, these exporters can ensure that their clients receive compliant and efficient solutions. Moreover, they harness local insights to adapt the machines to meet specific market needs, which can range from modifying grinding parameters to providing support for local materials.

The Future of Customized Centerless Grinders

As industries increasingly adopt automation and smart manufacturing technologies, the future of customized centerless grinders looks promising. With innovations like IoT integration, manufacturers can monitor machine performance in real time, which can lead to predictive maintenance and reduced downtime.

Furthermore, advancements in materials and grinding techniques are likely to enhance the capabilities of centerless grinders, allowing them to handle even more complex tasks. This evolution will open new avenues for manufacturers across various sectors, enabling them to achieve higher levels of productivity and precision.

Conclusion

In conclusion, the role of customized centerless grinder exporters is crucial in today’s manufacturing ecosystem. By providing tailored solutions that meet the diverse needs of different industries, these exporters not only contribute to increased efficiency and quality but also support global manufacturing efforts. As technology continues to evolve, the potential for customized centerless grinders will only grow, helping companies stay competitive in an increasingly complex market.