Custom Centerless Grinder Suppliers Elevating Precision Machining

In the realm of precision machining, the importance of high-quality grinding equipment cannot be overstated. Among these, centerless grinders stand out due to their ability to produce parts with exceptional accuracy and efficiency. For manufacturers seeking tailored solutions, custom centerless grinder suppliers offer a vital service that enhances the grinding process, ensuring that businesses can meet their specific production requirements.

Understanding Centerless Grinding

Centerless grinding is a machining process that allows for the grinding of cylindrical components without the need for centering devices. The workpiece is positioned between two wheels the grinding wheel and the regulating wheel. This setup supports two critical functions the grinding wheel shapes the part while the regulating wheel controls its speed and movement. The precision of this method makes it ideal for repeatable machining tasks across various industries, including automotive, aerospace, and consumer goods.

The Role of Custom Centerless Grinder Suppliers

While standard centerless grinders suffice for many applications, there are instances where customized solutions are necessary. Here, custom centerless grinder suppliers come into play. These suppliers work closely with manufacturers to design machines that meet specific production needs, such as part dimensions, materials, and performance requirements.

1. Tailored Solutions for Unique Needs Different industries have varying requirements, and a one-size-fits-all approach often leads to inefficiencies. Custom suppliers analyze the customer's operations to develop grinding solutions that enhance productivity. Whether it’s a modification in design, capacity adjustments, or specialized tooling, these suppliers provide options that optimize the grinding process.

2. Technology Integration With rapid advancements in technology, traditional grinding practices are evolving. Custom suppliers are at the forefront of integrating cutting-edge technology into their machines, such as automation, advanced monitoring systems, and software for enhanced precision. This integration allows for real-time adjustments, ensuring that quality standards are consistently met while minimizing waste.

3. Quality Control and Compliance Customized equipment often demands rigorous testing to meet industry standards. Custom centerless grinder suppliers implement strict quality control measures to ensure that each machine complies with both international standards and customer specifications. This attention to detail guarantees that businesses can confidently rely on their equipment to produce high-quality components.

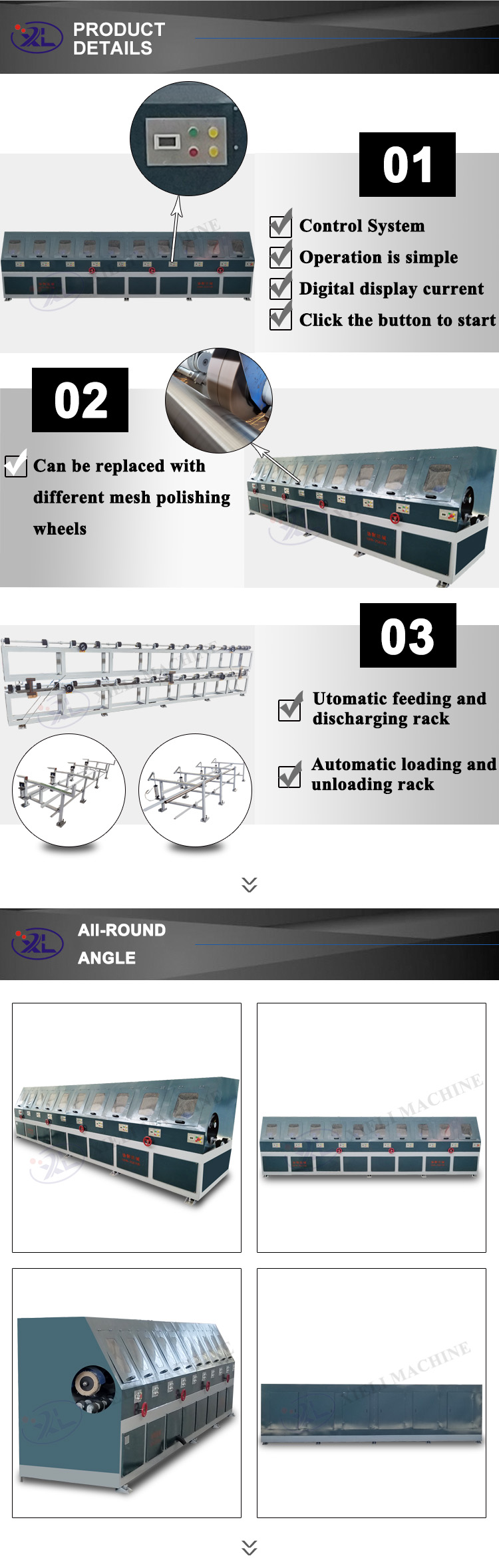

custom centerless grinder suppliers

4. After-Sales Support and Maintenance A reliable supplier goes beyond just selling machinery. They also provide ongoing support and maintenance services. Custom centerless grinder suppliers often have dedicated teams for after-sales service, ensuring that the machines operate at peak performance throughout their lifespan. This commitment helps companies avoid costly downtime and extends the life of their equipment.

Selecting the Right Supplier

Choosing the right custom centerless grinder supplier is crucial for businesses that prioritize precision and efficiency. Here are some factors to consider

- Experience and Expertise Suppliers with a proven track record in the industry are more likely to offer the expertise needed for custom solutions. Look for suppliers who have worked with businesses in similar sectors.

- Customization Capabilities Assess the supplier’s ability to provide tailored solutions. Ask for case studies or examples of previous customizations that have led to improved outcomes for clients.

- Technology and Innovation Inquire about the technology used in their machines. Suppliers who invest in research and development are likely to offer more advanced, efficient solutions.

- Reputation and Reviews Research the supplier’s reputation in the industry. Customer reviews and testimonials can provide valuable insights into their reliability and the quality of their products.

Conclusion

In conclusion, custom centerless grinder suppliers play a pivotal role in the manufacturing landscape. By offering tailored solutions that align with specific production needs, they enable companies to achieve higher levels of efficiency, precision, and quality. As technological advancements continue to reshape the industrial sector, the collaboration between manufacturers and suppliers will be essential for staying competitive. Investing in a custom centerless grinder not only enhances manufacturing capabilities but also significantly contributes to long-term business success.