Custom Centerless Grinder Rebuild Enhancing Precision and Efficiency

In the world of manufacturing, precision is paramount. For companies relying on high-volume production and intricate machining processes, the centerless grinder stands as a vital tool. However, like any machine, it can wear down over time, necessitating a rebuild. In recent years, the trend of custom centerless grinder rebuilds has emerged, offering companies the opportunity to enhance both precision and efficiency while maximizing their investment.

Understanding Centerless Grinding

Centerless grinding is a machining process that removes material from a workpiece using a grinding wheel. Unlike traditional methods where the piece is secured between two centers, centerless grinding allows for increased efficiency, as pieces are fed continuously through the machine. This method is particularly advantageous when dealing with small, cylindrical parts, which require a high level of precision and surface finish.

Reasons for a Rebuild

Over time, the components of a centerless grinder can degrade, leading to a decline in performance. Factors such as wear and tear, misalignment, and outdated technology can contribute to inefficiencies, increased cycle times, and compromised product quality. A rebuild can address these issues by refurbishing key components, updating technology, and ensuring that the machine is operating at its optimal level.

Benefits of a Custom Rebuild

1. Tailored Solutions One of the most significant advantages of a custom rebuild is the ability to tailor the machine to specific needs. Manufacturers can choose to upgrade various components such as spindles, motors, controls, and grinding wheels based on their production requirements. This customization ensures that the grinder operates efficiently, producing high-quality parts that meet the exacting standards of today’s market.

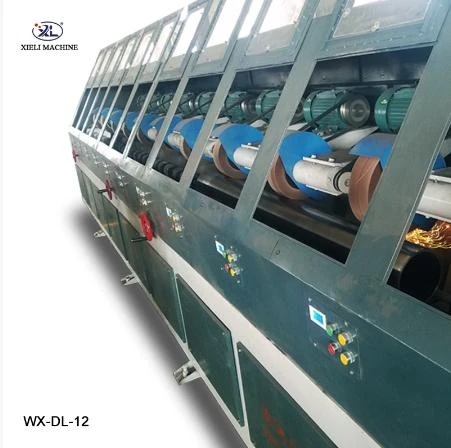

custom centerless grinder rebuild

2. Cost-Effectiveness Rebuilding a centerless grinder can be a more cost-effective solution compared to buying a new machine. The process allows companies to extend the life of their current equipment, reducing capital expenditure and minimizing downtime associated with installation and training on a new system.

3. Enhanced Efficiency Upgrading to contemporary controls and technology during the rebuild can significantly enhance the grinder's efficiency. Modern systems often incorporate advanced automation features, enabling faster cycle times and improved accuracy. This upgrade can lead to increased production rates, ultimately benefiting the bottom line.

4. Sustainability In an age where sustainability is becoming increasingly important, rebuilding machinery rather than replacing it can help reduce waste. By extending the life of existing equipment, companies can minimize their environmental impact while still achieving high standards of production.

The Rebuilding Process

A comprehensive rebuild typically involves several key steps. First, the grinder is disassembled, and each component is thoroughly inspected. Worn parts are either rebuilt or replaced with high-quality components. The next stage involves realignment and calibration to ensure that the machine meets precise specifications. Finally, the system is tested to confirm that it performs at or above the standards set by the original manufacturer.

Conclusion

In conclusion, a custom centerless grinder rebuild presents an excellent opportunity for manufacturers looking to improve their production capabilities. By choosing a rebuild over a complete replacement, companies not only save costs but also enhance their machines' precision and efficiency. With tailored solutions that address specific production needs and modern upgrades that keep pace with technological advances, a rebuilt centerless grinder can serve as a reliable asset for years to come. As the industry continues to evolve, investing in a rebuild may well be the key to maintaining a competitive edge.