Understanding the Costs of Custom Centerless Grinders

When it comes to precision manufacturing, centerless grinders play a crucial role in achieving the tight tolerances and surface finishes required by various industries. For businesses looking to optimize their production processes, investing in a custom centerless grinder can be an excellent choice. However, one of the primary considerations when opting for this type of machinery is the price. Understanding what contributes to the cost of custom centerless grinders can help manufacturers make informed purchasing decisions.

What is a Custom Centerless Grinder?

A centerless grinder is a type of grinding machine that does not require any centering of the workpiece. Instead, the workpiece is supported by a work rest blade, with abrasive wheels positioned in a way that enables them to grind the piece in a continuous motion. A custom centerless grinder is tailored to meet the specific needs of a manufacturing operation, whether that involves optimizing dimensions, adjusting feed rates, or accommodating unique materials.

Factors Affecting the Price of Custom Centerless Grinders

1. Design Specifications Custom centerless grinders are designed based on the unique requirements of a specific application. The complexity of the design directly influences the cost. A grinder designed to handle multiple part sizes or intricate shapes will typically be more expensive than one built for a single application.

2. Material Quality The materials used in the construction of the grinder significantly impact the overall price. High-quality, durable materials that resist wear and tear come at a higher cost but offer longevity and reliability, ultimately providing better value over time.

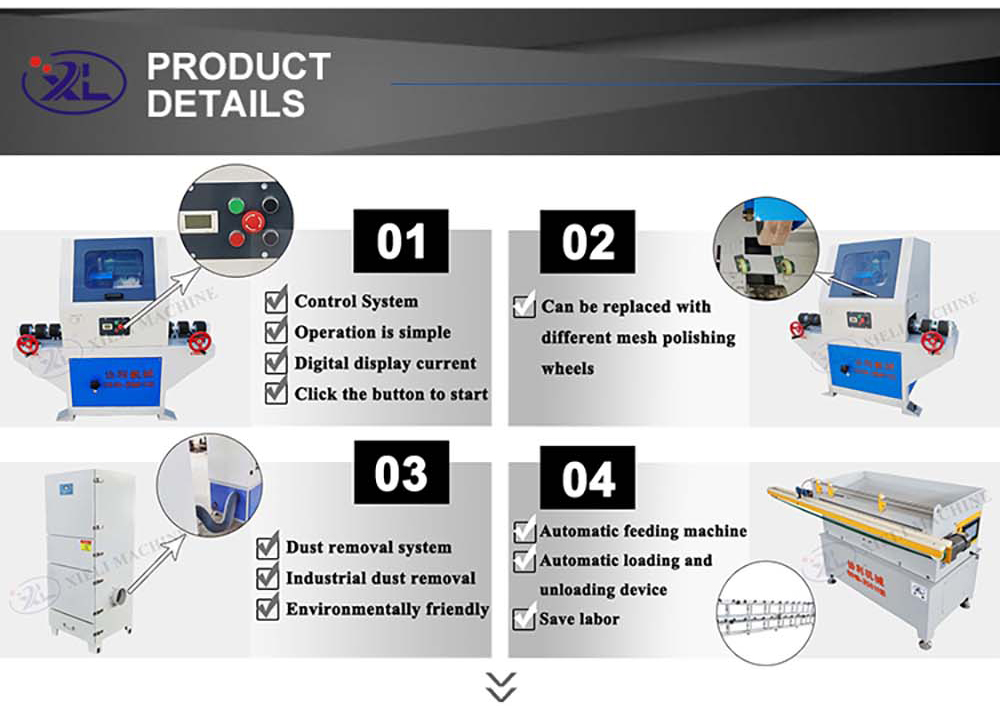

3. Features and Technology Advanced features such as automation, computer numerical control (CNC), and integrated monitoring systems can add to the cost of a centerless grinder. While these features can increase initial investment, they also enhance productivity and reduce labor costs, making them worthwhile in the long run.

custom centerless grinder price

4. Brand Reputation Established brands often charge a premium for their machinery due to their reputation for quality, service, and support. While investing in a reputable brand may seem costly at first, it often leads to fewer issues and higher resale values.

5. Customization Level The extent of customization required for a machine is another critical factor. Custom solutions designed from scratch or significantly modified from standard models require more engineering time and resources, thereby increasing costs.

6. Installation and Maintenance The price of a custom centerless grinder doesn’t end with the purchase. Installation, training, and maintenance costs can also add up. It is essential to factor these additional expenses into the overall budget when considering a purchase.

Estimating the Price

The price range for custom centerless grinders can vary widely, typically starting from tens of thousands to several hundred thousand dollars depending on the factors mentioned above. It is wise for businesses to conduct thorough research and request quotes from multiple suppliers. Some may offer financing options or leasing arrangements, providing flexible payment options that can ease the financial burden.

Conclusion

Investing in a custom centerless grinder is a significant decision for any manufacturing business. Understanding the components that influence the price is critical in making a well-informed choice. By considering design specifications, material quality, advanced features, brand reputation, and the costs of installation and maintenance, manufacturers can select a machine that not only fits their budget but also enhances their production capabilities. Ultimately, the right centerless grinder can lead to increased efficiency, improved product quality, and higher profitability in an increasingly competitive marketplace.