Custom Centerless Bar Grinding Machine Enhancing Precision and Efficiency in Metalworking

In the realm of metalworking, precision plays a pivotal role in determining the quality and performance of finished products. Among various machining processes, centerless grinding has emerged as a vital technique for achieving the high standards required in modern manufacturing industries. Specifically, custom centerless bar grinding machines offer tailored solutions that enhance both efficiency and accuracy, catering to the diverse needs of engineers and manufacturers.

Centerless grinding, unlike traditional grinding methods, does not require a fixed axis for the workpiece. Instead, it utilizes a unique setup where the workpiece is placed between two rotating wheels. The grinding wheel, which removes material, and the regulating wheel, which controls the speed and movement, work in unison to produce smooth and precise cylindrical components. This process is particularly ideal for machining long and narrow parts, such as bars, shafts, and tubes, making it indispensable for industries ranging from automotive to aerospace.

One of the standout features of custom centerless bar grinding machines is their adaptability to specific requirements. Manufacturers often encounter varying specifications based on the types of materials being processed and the desired tolerances. A custom machine can be designed with precision controls, tailored tooling, and specialized configurations to handle different sizes, shapes, and materials, ensuring optimal performance in every application. By incorporating advanced technology, such as CNC (Computer Numerical Control), these machines offer enhanced automation, reducing the potential for human error while increasing production speeds.

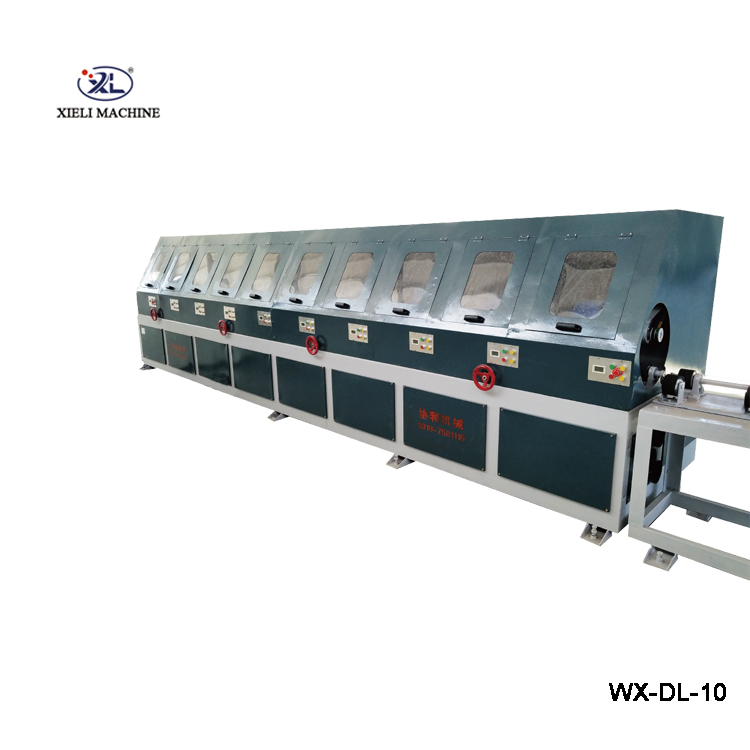

custom centerless bar grinding machine

The flexibility of custom centerless grinding machines also allows for the integration of additional processes, such as in-feed and through-feed grinding. In-feed grinding is particularly useful for components that require precise dimensional control at specific points along the length, while through-feed grinding is ideal for continuous production of straight bars. This versatility enables manufacturers to streamline their operations, reducing the need for multiple setups and thus saving time and resources.

Investment in custom centerless bar grinding machines not only boosts productivity but also significantly improves the quality of the finished products. With the capability to achieve tighter tolerances and superior surface finishes, manufacturers can deliver components that meet stringent performance criteria. This advantage is critical in industries where even the slightest variation can lead to failure of the final product, affecting safety and functionality.

Moreover, many custom machines incorporate features designed to enhance user experience and maintenance efficiency. Intuitive interfaces, streamlined maintenance procedures, and robust construction contribute to reduced downtime, ensuring that production schedules remain intact. As businesses strive to remain competitive in an ever-evolving market, these advancements in machine design and operation become essential.

In conclusion, custom centerless bar grinding machines represent a significant leap forward in the metalworking industry, offering unparalleled precision, efficiency, and adaptability. By meeting the specific needs of manufacturers, these machines facilitate the production of high-quality components that adhere to exacting standards. As technology continues to advance, the importance of tailored solutions in machining processes will only grow, cementing the role of custom centerless grinding machines as a cornerstone of modern manufacturing. Investing in such innovative machinery demonstrates a commitment to quality, performance, and the future of the industry.