Custom Cinco 15 Centerless Grinder Parts Enhancing Precision and Efficiency

When it comes to precision machining, the centerless grinder stands out as an essential tool in various manufacturing processes. Among the popular models in the market, the Custom Cinco 15 centerless grinder holds a prominent position, known for its reliability and efficiency. However, like any complex machine, it requires a range of quality replacement parts to maintain optimal performance. This article explores the importance of custom components for the Cinco 15 and how they contribute to enhanced machining capabilities.

Custom Cinco 15 Centerless Grinder Parts Enhancing Precision and Efficiency

One key benefit of using custom parts is that they are tailored to fit the specific requirements of the Cinco 15 grinder. OEM (Original Equipment Manufacturer) parts may be readily available, but they often come with generic specifications that may not address all operational nuances. Custom parts can be engineered to enhance specific functionalities, leading to improved accuracy and efficiency during the grinding process. This is particularly important in sectors where tolerances are stringent, such as aerospace and automotive components.

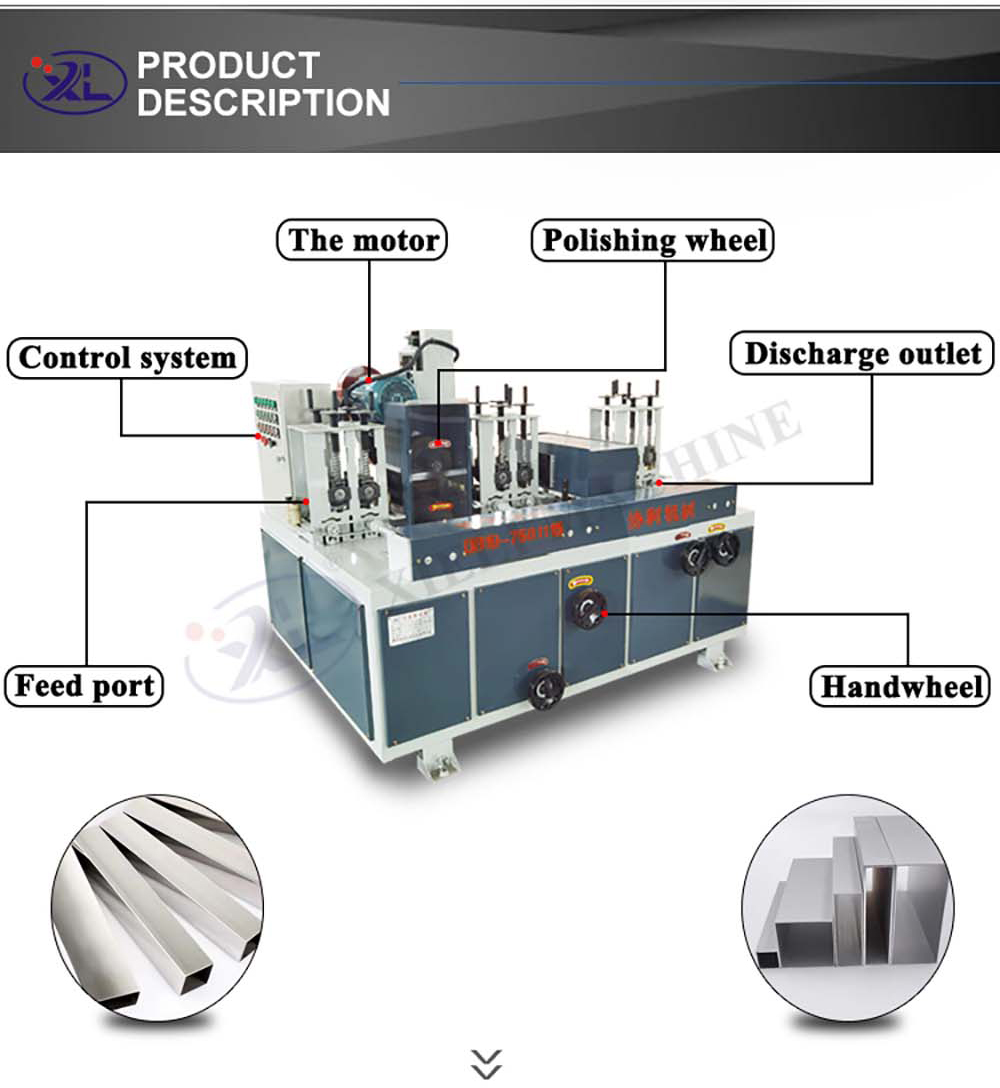

custom cinco 15 centerless grinder parts

Another advantage of custom parts is the opportunity for upgrades. With advancements in technology, certain components can be redesigned for better performance. For instance, custom grinding wheels can feature improved materials or designs that can enhance grinding speed or particle removal. Similarly, other parts like the feed mechanism or drive belts can be optimized to reduce downtime and enhance overall productivity.

Moreover, sourcing custom parts for the Cinco 15 is not just about performance; it also relates to reducing long-term operational costs. While the initial investment in custom components may seem higher, their precision and durability can lead to a significant reduction in maintenance needs and machine downtime. Fewer breakdowns mean more consistent production schedules, ultimately translating to cost savings over time.

In addition to performance and cost advantages, custom parts also ensure that compatibility is maintained with existing machinery. The risk of operational issues arising from ill-fitting components can lead to costly delays in production. Custom-fabricated parts can be engineered with exact specifications in mind, ensuring seamless integration and functionality.

In conclusion, the Custom Cinco 15 centerless grinder is a powerhouse in the machining industry, and the importance of quality replacement parts cannot be overstated. Opting for custom components tailored to the specific needs of the grinder not only enhances precision and efficiency but also contributes to long-term cost savings and machine reliability. By investing in the right parts, manufacturers can ensure that their grinding operations remain competitive and sustainable in an ever-evolving market landscape.