Custom Junker Centerless Grinder Revolutionizing Precision Machining

In the world of precision machining, the demand for high-quality, efficient, and reliable grinding solutions is ever-growing. A key player in fulfilling this need is the custom Junker centerless grinder, which has become a staple for manufacturers aiming to enhance their production capabilities. This article delves into the features, benefits, and applications of custom Junker centerless grinders, showcasing how they are revolutionizing the machining landscape.

The Concept of Centerless Grinding

Centerless grinding is a machining process that removes material from a workpiece, typically cylindrical in shape, without the need for clamping the part between centers. Instead, the workpiece is supported by two wheels the grinding wheel and the regulating wheel. The grinding wheel performs the actual grinding, while the regulating wheel controls the rotation and feed rate of the workpiece. This configuration allows for high precision, efficiency, and throughput, making it an ideal choice for various industries.

Custom Solutions for Diverse Applications

One of the most significant advantages of Junker centerless grinders is their ability to be customized according to specific production needs. Manufacturers often face unique challenges based on the materials they work with, the dimensions of their components, and the desired tolerances. Custom Junker grinders can be tailored to meet these requirements, ensuring optimized performance and superior results.

For instance, the machine can be configured to accommodate different wheel sizes, shapes, and abrasive materials, allowing operators to switch between various grinding styles quickly. This flexibility is crucial for companies that produce a diverse range of parts, as it minimizes downtime and maximizes productivity.

Advanced Technology

Junker is known for its commitment to innovation and advanced technology. Their centerless grinders incorporate state-of-the-art features such as CNC control systems, allowing for precise adjustments and programming. This level of automation not only enhances accuracy but also reduces the potential for human error, ensuring consistent quality in every batch produced.

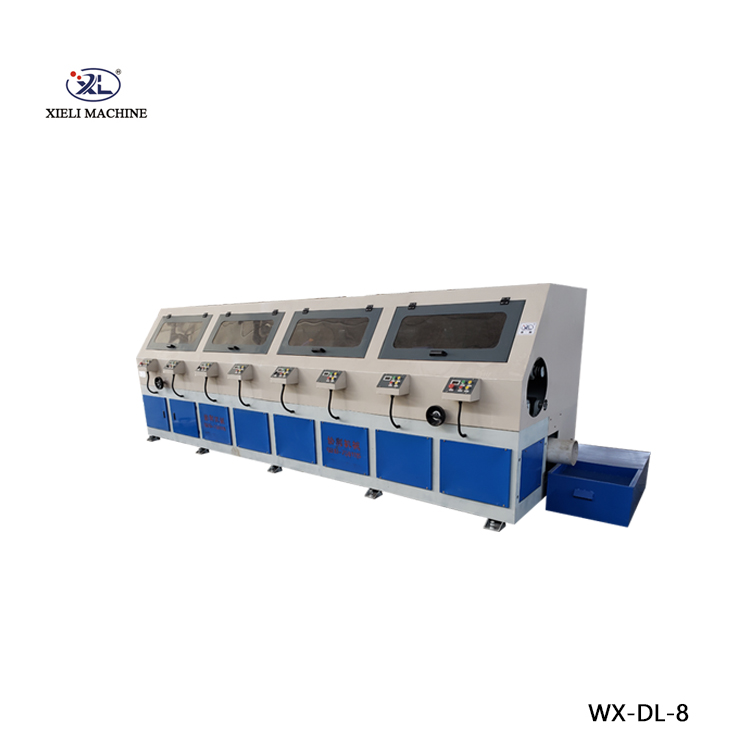

custom junker centerless grinder

Additionally, Junker centerless grinders often come equipped with sophisticated monitoring systems that provide real-time feedback on the grinding process. These systems enable operators to identify any inconsistencies or deviations swiftly, facilitating proactive maintenance and minimizing disruptions in production.

Benefits of Using Custom Junker Centerless Grinders

1. Enhanced Precision Custom configurations allow for tighter tolerances and high repeatability, which are essential in industries like aerospace, automotive, and medical devices.

2. Increased Efficiency The optimized grinding process reduces cycle times and improves throughput, meaning manufacturers can meet growing demands without sacrificing quality.

3. Versatility The ability to customize engagement settings, wheel selection, and operational parameters makes Junker grinders suitable for a wide range of materials, from steel and aluminum to plastics and ceramics.

4. Cost-Effectiveness While the initial investment may be higher than standard grinding machines, the long-term savings from decreased waste, fewer rejected parts, and lower operational costs justify the expense.

Conclusion

In conclusion, custom Junker centerless grinders embody the future of precision machining. Their adaptability, advanced technology, and focus on quality ensure that manufacturers remain competitive in an increasingly demanding marketplace. As industries continue to evolve and require more sophisticated solutions, the role of custom centerless grinders will undoubtedly become more crucial, driving innovation and efficiency in production processes worldwide.