Understanding Centerless Grinders A Key Component for Precision Machining

In the world of precision machining, centerless grinders play a crucial role in enhancing productivity and efficiency. Unlike conventional grinding methods, centerless grinding offers unique advantages that make it a popular choice for many manufacturing processes. In this article, we’ll explore the importance of centerless grinders and why they are sought after in the industry.

Centerless grinders operate on a simple yet effective principle. Instead of using centers to hold the workpiece, they rely on a combination of a grinding wheel, a regulating wheel, and a work support blade. This setup allows the grinding wheel to remove material from the outside diameter while the regulating wheel controls the speed and positioning of the part. As a result, centerless grinding can achieve remarkable precision and consistency, often with higher throughput than traditional methods.

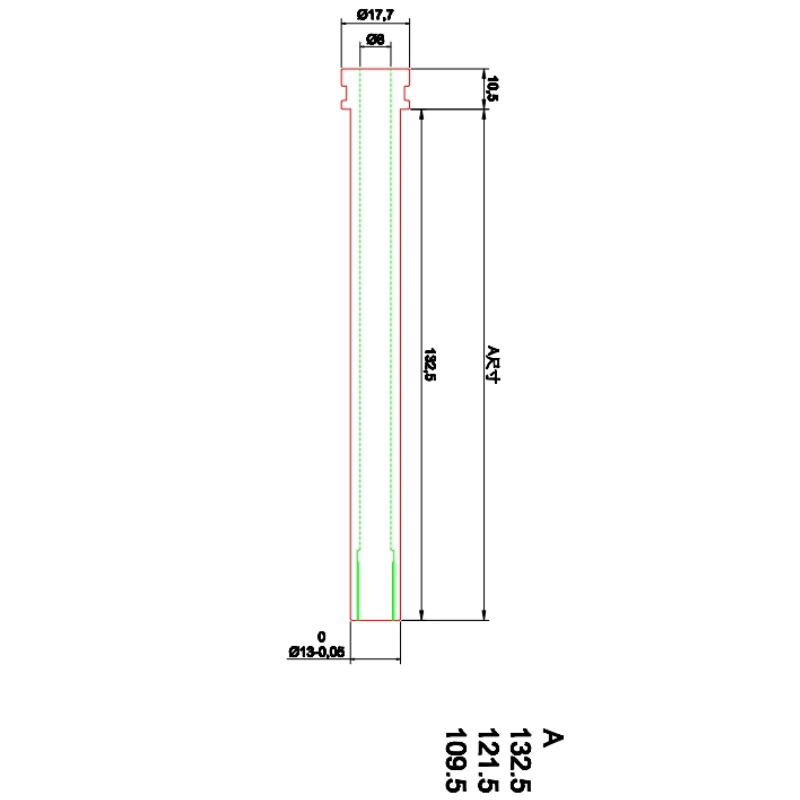

One of the most significant advantages of centerless grinding is its ability to handle long and slender workpieces. This capability makes it exceptionally suitable for parts that require tight tolerances, such as shafts, pins, and tubing. Additionally, centerless grinding can accommodate multiple parts simultaneously, further increasing productivity and reducing manufacturing costs.

craigslist.org dedtru centerless grinder quotes

For businesses looking to enhance their machining capabilities, the market offers a wide range of centerless grinders, from manual machines to fully automated systems. The choice largely depends on the specific requirements of the operation, including the type of materials being machined, the desired tolerances, and production volume. Investing in a high-quality centerless grinder can be a game-changer for companies aiming to improve efficiency and maintain a competitive edge.

When exploring options for centerless grinders, platforms like Craigslist can be valuable resources. Many sellers list both new and used machines, allowing businesses to find suitable equipment that fits their budget. Buyers should thoroughly assess the condition of used grinders, checking for wear and tear and ensuring that all components are in good working order. It's also essential to verify the seller's reputation and read reviews to avoid potential pitfalls.

Additionally, obtaining quotes from multiple vendors can help gauge the market price for centerless grinders. Comparing prices and features can lead to better-informed decisions, ensuring that businesses invest in the right machinery to meet their needs.

In conclusion, centerless grinders are indispensable tools in the precision machining landscape. Their ability to provide high-quality finishes on various workpieces, coupled with their efficiency, makes them a popular choice among manufacturers. Whether a business is looking to purchase a new machine or find reliable used equipment, resources like Craigslist can help facilitate the search. By investing in a centerless grinder, companies can achieve greater precision, reduce production time, and ultimately drive their success in a competitive market.