The Pricing and Overview of Square and Rectangle Tube Polishing Machines

In the world of metalworking and fabrication, the finishing process plays a crucial role in determining the final quality and aesthetics of products. Among the various finishing processes, polishing stands out for its ability to enhance the surface quality of materials, particularly in square and rectangle tube manufacturing. The demand for square and rectangle tube polishing machines has surged as industries strive for perfection in their products. This article explores the features, pricing, and significance of these machines in modern manufacturing.

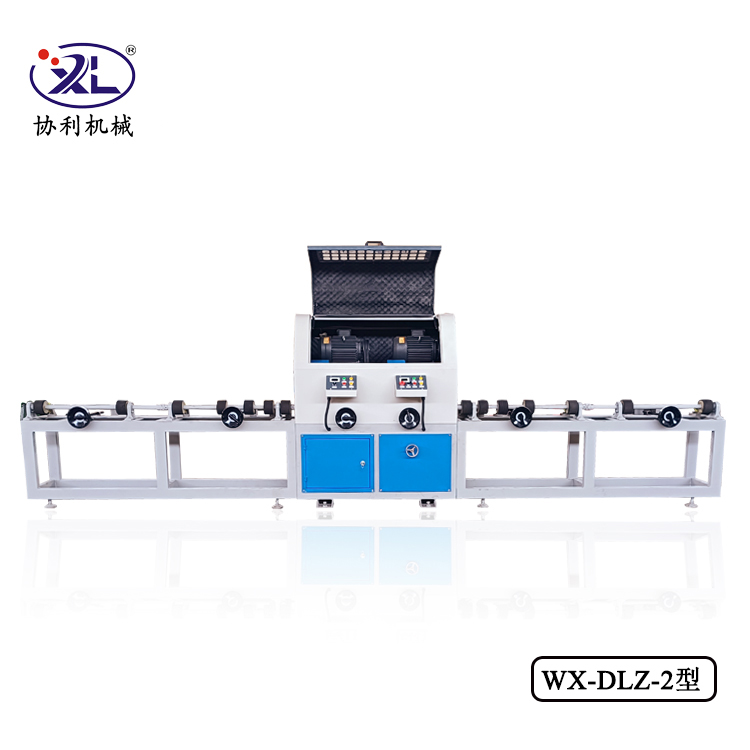

Features of Square and Rectangle Tube Polishing Machines

Square and rectangle tube polishing machines are specialized equipment designed to treat the surface of tubular materials, refining their texture and appearance. These machines are capable of delivering consistent polishing results, which is essential for high-quality output. Key features often include adjustable polishing speeds, a range of polishing belts, and automated feeding systems that cater to different tube dimensions. Advanced models may also incorporate CNC technology, allowing for precise control over the polishing process and enabling manufacturers to achieve uniform finishes across large production runs.

Moreover, safety features are paramount in these machines, with many incorporating guards and emergency stop functions to protect operators. The versatility of these machines allows them to handle various materials, including stainless steel, aluminum, and other alloys, making them indispensable in industries ranging from automotive to furniture fabrication.

Understanding the Pricing Landscape

The price of square and rectangle tube polishing machines can vary significantly based on several factors, including machine size, brand, capabilities, and additional features. Entry-level models suitable for small to medium-sized operations can start from around $5,000, primarily designed for basic polishing tasks. These machines usually have limited capabilities but are an excellent option for businesses looking to enhance their production processes without a hefty initial investment.

In contrast, high-end models equipped with advanced technology and capable of handling larger production volumes can reach prices of $50,000 and above. These machines typically offer features such as multi-axis polishing, automated loading and unloading, and enhanced control systems that provide greater precision and speed. For businesses with substantial production requirements, investing in premium polishing machines can lead to significant efficiency gains and higher-quality output.

square rectangle tube polishing machine pricelist

Factors Influencing Prices

Several factors influence the pricing of polishing machines, including

1. Technical Specifications The complexity and capabilities of a machine can greatly affect its cost. Machines offering automation, advanced controls, and higher production capacities generally demand higher prices.

2. Brand Reputation Well-established brands known for reliability and customer support may command premium prices compared to lesser-known manufacturers.

3. Market Demand Economic conditions and market trends can impact prices. During periods of high demand, prices may rise due to increased competition for a limited number of machines.

4. Customizations and Accessories Additional features such as custom polishing head attachments or enhanced safety mechanisms can add to the total cost of the machine.

Conclusion

Investing in a square or rectangle tube polishing machine is a significant decision for any manufacturing business focused on achieving high-quality products. While the pricing landscape varies widely, it’s essential for business owners to consider their specific needs, production volume, and the potential return on investment. By selecting the right polishing machine, manufacturers can enhance the aesthetic appeal and durability of their products, ultimately leading to greater customer satisfaction and business success. As manufacturing technologies continue to evolve, staying informed on equipment options and price trends will enable businesses to remain competitive in the rapidly changing market.