Centerless Belt Grinder Service Ensuring Precision and Efficiency

Centerless belt grinders are essential machines in various industries, particularly in manufacturing and metalworking. They are used for grinding and finishing materials to achieve precise dimensions and surface quality. Given the complexity of these machines, regular servicing is crucial to maintain optimal performance and prevent costly downtimes.

Understanding Centerless Belt Grinders

Centerless belt grinders operate on a unique principle that allows workpieces to be positioned and removed without the need for support between the grinding wheels. This eliminates the need for center holes on the workpiece, making it easier to grind long or irregularly shaped items. The grinding action follows a continuous process, facilitated by a belt that rotates around a series of pulleys, ensuring even wear and improving the longevity of the machine.

Importance of Regular Maintenance

Just like any other heavy machinery, centerless belt grinders require regular maintenance to function effectively. Regular servicing can help identify potential issues before they escalate into major problems. This not only extends the lifespan of the machine but also enhances the quality of the finished products.

Key areas for maintenance include

1. Belt Inspection The grinding belt should be regularly checked for wear and tear. A worn-out belt can lead to subpar grinding results and can cause damage to the workpiece. It’s essential to replace belts at the first sign of significant wear.

2. Alignment Checks Proper alignment of the machine's components is vital for achieving precise grinding. Misalignment can cause uneven wear on the belt and lead to inconsistencies in the finished product. Regular alignment checks and adjustments should be part of the maintenance routine.

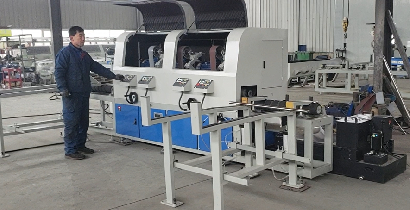

centerless belt grinder service

3. Lubrication The moving parts of the grinder should be properly lubricated to reduce friction and wear. Regular lubrication not only ensures smooth operation but also prevents overheating, which can cause damage to bearings and motors.

4. Cleaning Dust and debris can accumulate around and inside the machine, potentially affecting its performance. Regular cleaning schedules should be established to keep the machine free of contaminants that could hinder its operation.

5. Component Replacement Critical components such as bearings, pulleys, and motors may need to be replaced periodically. Keeping track of the wear rates of these components can prevent unexpected failures during operation.

Signs That Your Grinder Needs Service

Awareness of symptoms indicating that a centerless belt grinder needs service is essential. Increased vibration, unusual noises, or inconsistent grinding performance are telltale signs of potential issues. Operators should be trained to recognize these signs and take immediate action, which may involve consulting a professional service provider.

Conclusion

In conclusion, regular maintenance and servicing of centerless belt grinders are crucial for ensuring precision and efficiency in industrial applications. By implementing a robust maintenance schedule that includes inspection, alignment checks, lubrication, cleaning, and prompt replacement of worn components, businesses can ensure their investment in these machines pays off in the long run.

Moreover, fostering a culture of proactive maintenance can significantly reduce the likelihood of unexpected breakdowns and enhance production reliability. As industries continue to evolve and demand higher standards of quality, understanding and prioritizing centerless belt grinder service will be instrumental in achieving operational excellence.