The Heart of Precision Centerless Grinding Machine Parts

In the realm of modern manufacturing, precision is paramount. Among the various machining processes, centerless grinding stands out as a highly efficient method for shaping and finishing cylindrical parts. At the core of this process is the centerless grinding machine, which operates without the need for part holding fixtures. Instead, it relies on a combination of clever machine design and precision-engineered components. In this article, we explore the crucial parts of centerless grinding machines and the importance of their manufacturing.

Centerless grinding machines consist of several key components, each playing a vital role in the grinding process. The three main elements include the grinding wheel, the regulating wheel, and the workpiece support. The grinding wheel, typically made from abrasive materials, is responsible for removing material from the workpiece. Its performance is vital, as it directly affects the accuracy of the grinding operation. Quality grinding wheels are manufactured to specific standards and require careful balancing to ensure even wear and consistent surface finish.

The regulating wheel, on the other hand, is critical for controlling the workpiece's rotation and feed rate. Positioned at a slight angle, the regulating wheel grips the workpiece and guides it through the grinding zone. This component is crucial in maintaining the desired shape and dimensions of the part. The materials used in the construction of the regulating wheel must provide optimal friction to ensure the workpiece doesn’t slip.

Another essential part of a centerless grinding machine is the work rest. This component supports the workpiece as it passes through the grinding process, providing stability and alignment. The design of the work rest must allow for easy adjustment to accommodate different sizes and shapes of parts, further emphasizing the need for precision engineering in the manufacturing of these machines.

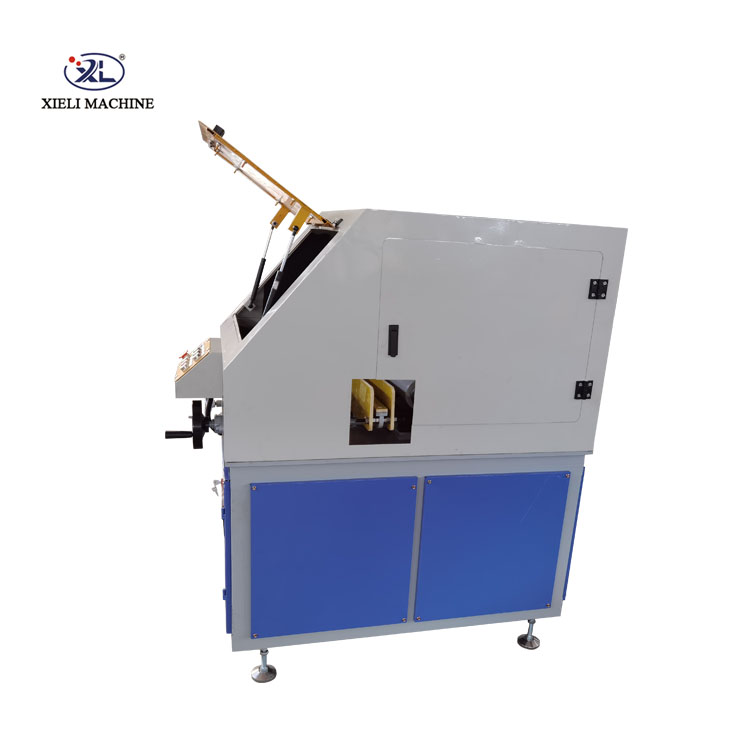

centerless grinding machine parts factory

Beyond these primary components, centerless grinding machines also include various supporting structures and systems, such as coolant delivery systems, which play a significant role in enhancing the grinding process. Coolants help dissipate heat generated during grinding, reducing the risk of damaging the workpiece and extending the life of the grinding wheel. Proper coolant management is essential for maintaining the precision and efficiency of the grinding operation.

The manufacturing of centerless grinding machine parts requires advanced machining techniques and strict quality control. Factories specializing in these components often utilize CNC (Computer Numerical Control) technology to achieve the high tolerances necessary for proper machine operation. Skilled engineers and technicians oversee the production process, ensuring that each part meets rigorous specifications and standards.

Furthermore, the global demand for high-quality centerless grinding machines has led to increased investment in R&D and innovation within factories. New materials and processes are being developed, aimed at improving machine efficiency and reducing production costs. This evolution is crucial, particularly as industries such as automotive, aerospace, and medical devices continue to require precision machined components.

In conclusion, the importance of precise and durable parts in centerless grinding machines cannot be overstated. The performance and efficiency of these machines hinge on the quality of their components, from the grinding and regulating wheels to the work rests and support structures. As technology advances, so too does the potential for innovation in the manufacturing of these essential parts, ultimately shaping the future of precision machining. Investing in high-quality production processes ensures that the centerless grinding machines of tomorrow will continue to meet the ever-increasing demands for precision and efficiency in manufacturing.