CNC Centerless Grinder Suppliers and Exporters An Overview

In the world of manufacturing, precision and efficiency are paramount. One crucial machine that plays a significant role in achieving these goals is the CNC centerless grinder. This technology has revolutionized the grinding process, providing manufacturers with the ability to produce high-quality components with tight tolerances. As industries continue to evolve, the demand for specialized machinery, including CNC centerless grinders, has surged. Consequently, suppliers and exporters of these machines are increasingly vital players in the global market.

Understanding CNC Centerless Grinding

Before diving into the realm of suppliers and exporters, it's important to understand what CNC centerless grinding entails. Unlike traditional grinding methods that require the workpiece to be fixed between centers, centerless grinding allows the workpiece to be ground without any physical support. The grinding occurs between two wheels the grinding wheel, which removes material, and the regulating wheel, which controls the speed and position of the workpiece.

This method is particularly advantageous for producing cylindrical parts with a high degree of symmetry and precision. Applications range from automotive components to medical devices and aerospace parts, showcasing the versatility and necessity of CNC centerless grinders in modern manufacturing.

The Role of CNC Centerless Grinder Suppliers

CNC centerless grinder suppliers are critical in providing manufacturers with the necessary equipment to enhance their production capabilities. These suppliers typically offer a wide range of machines tailored to different specifications, ensuring that clients can find the right solution for their unique needs.

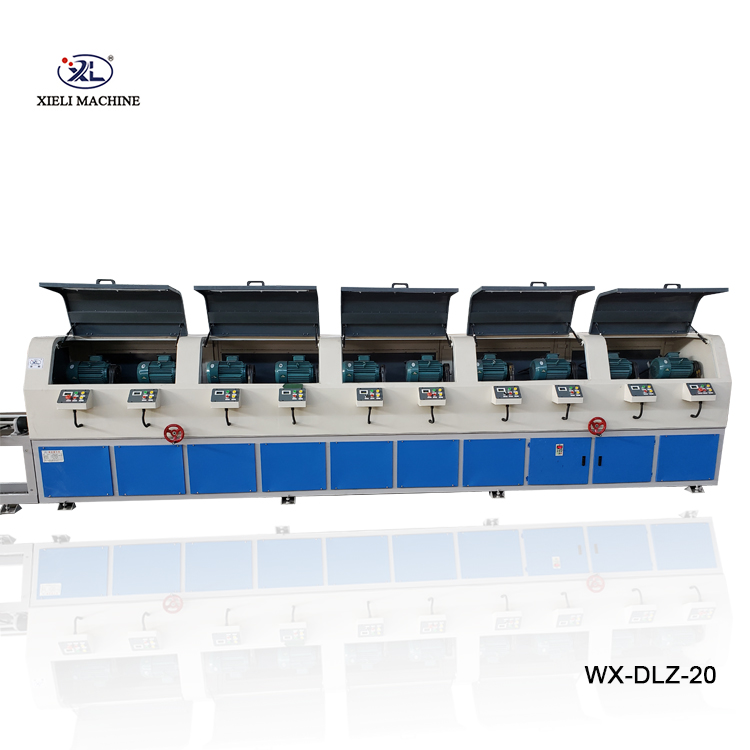

1. Diverse Product Offerings Suppliers often carry various models of CNC centerless grinders, accommodating different sizes and types of workpieces. Some machines may be designed for heavy-duty production, while others are optimized for smaller runs or specialized tasks.

2. Customization Many suppliers offer customized solutions. Manufacturers can request specific configurations or features that meet their operational requirements. This flexibility is particularly crucial for industries with unique specifications, such as aerospace and medical manufacturing.

3. Technical Support A reputable supplier provides not only machines but also technical support and guidance. Installation, maintenance, and operator training are essential services that ensure the equipment operates efficiently and safely.

cnc centerless grinder suppliers exporter

4. Quality Assurance The best suppliers source their machines from reputable manufacturers known for high-quality engineering. This focus on quality is vital, as it directly impacts the longevity and performance of the machines.

Exporting CNC Centerless Grinders Worldwide

With globalization, many CNC centerless grinder suppliers have expanded their reach beyond domestic markets. Exporting these machines to various countries has become a significant aspect of their business model. The following factors contribute to the growth of exports in this sector

1. Increased Global Demand As international industries ramp up production to meet global demand, the need for high-quality grinding machines has surged. CNC centerless grinders are often in high demand across continents, including North America, Europe, and Asia.

2. Compliance with International Standards Exporters must ensure that their machines comply with international safety and quality standards. This compliance not only facilitates smoother trade but also enhances the reputation of the suppliers in global markets.

3. Market Competitiveness The exporting landscape is competitive, with numerous suppliers vying for market share. Companies that can provide superior products, reliable customer service, and cost-effective solutions are more likely to succeed in international markets.

4. Technological Advancements The rapid pace of technological advancements in manufacturing necessitates that suppliers and exporters stay at the forefront of innovation. Modern CNC centerless grinders often feature advanced software, connectivity, and automation capabilities, making them increasingly valuable to manufacturers worldwide.

Conclusion

In summary, CNC centerless grinder suppliers and exporters play a crucial role in the manufacturing landscape. As industries seek greater efficiency and precision, the demand for high-quality CNC centerless grinding machines continues to rise. Suppliers who understand the needs of their clients, provide customized solutions, and offer robust support will undoubtedly thrive in this competitive sector. As globalization continues to shape the market, those who excel in exporting will also contribute significantly to meeting the ever-growing demands of consumers worldwide.