Choosing the Right CNC Centerless Grinder Supplier

In today's manufacturing landscape, precision engineering and efficient production processes are paramount. One of the key machines facilitating this is the CNC (Computer Numerical Control) centerless grinder. This specialized equipment is integral in achieving high levels of accuracy and efficiency while grinding cylindrical workpieces. As such, selecting the right CNC centerless grinder supplier is critical for any manufacturing business aiming to maintain competitive advantage and operational excellence.

Understanding CNC Centerless Grinders

CNC centerless grinders are designed to shape and finish parts without the need for a holding fixture. The process involves placing a workpiece between two rotating wheels a grinding wheel and a regulating wheel. The grinding wheel removes material to achieve the desired dimensions, while the regulating wheel controls the speed and movement of the workpiece. The precision achieved with CNC technology allows manufacturers to produce high volumes of parts with exact specifications.

The Importance of Choosing the Right Supplier

When investing in CNC centerless grinders, the choice of supplier significantly impacts business outcomes. A reliable supplier not only provides high-quality machines but also offers essential services such as installation, training, maintenance, and technical support. This pivotal relationship can influence production efficiency, product quality, and the overall return on investment (ROI).

Key Factors to Consider When Selecting a Supplier

1. Quality of Machinery The foremost consideration is the quality of the CNC centerless grinders offered. Look for suppliers known for their durable machines built with precision engineering. Ensure that the products comply with international quality standards and have passed rigorous testing.

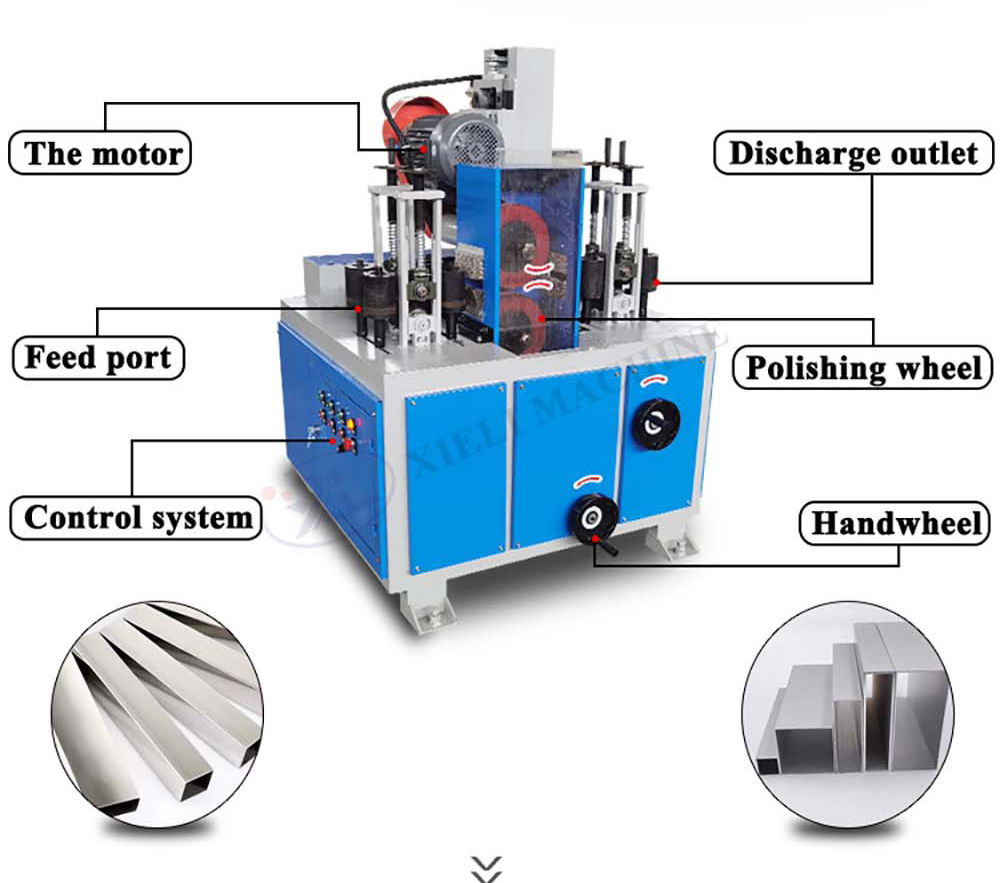

cnc centerless grinder supplier

2. Customization Options Every manufacturing process is unique, and so are its requirements. A good supplier should offer customization options tailored to meet specific production needs, ensuring that the equipment fits seamlessly into existing operations.

3. Technical Expertise A supplier with extensive technical knowledge can provide invaluable insights into the most suitable machinery for your specific applications. Their expertise can guide you in understanding the capabilities of different models and help you make an informed decision.

4. Customer Service and Support Post-purchase support is crucial in minimizing downtime and ensuring consistency in production. Evaluate the supplier's customer service track record, including their availability for troubleshooting, maintenance services, and the provision of spare parts.

5. Reputation and Reviews Research the supplier’s reputation in the industry. Look for customer reviews, testimonials, and case studies that reflect their previous work and client satisfaction levels. A supplier with a solid reputation for reliability and quality is often more trustworthy.

6. Cost and Financing Options While price shouldn’t be the sole factor driving your decision, it is still crucial. Compare the costs of different suppliers, and explore financing options that may be available to ease the investment burden.

7. Lead Times and Delivery Assess the supplier’s lead times for delivering the equipment. Timely delivery is essential to keep your production schedule on track, so ensure that the supplier can meet your deadlines.

Conclusion

Selecting the right CNC centerless grinder supplier is a strategic decision that can affect your manufacturing operations for years to come. By taking the time to evaluate potential suppliers based on the factors mentioned, businesses can find a partner that aligns with their needs and helps drive success. With the right CNC centerless grinder and a supportive supplier, manufacturers can enhance productivity, improve product quality, and ultimately achieve greater profitability in a competitive market.