Centerless Grinders A Comprehensive Overview of CNC Technology in Precision Manufacturing

In the realm of precision manufacturing, CNC (Computer Numerical Control) centerless grinders play an indispensable role. These advanced machines are designed to grind cylindrical parts without the need for a supporting structure, a unique process that enhances efficiency and accuracy in production environments. This article will explore the significance of CNC centerless grinders, their operational principles, applications, and the benefits they offer to manufacturers.

Understanding CNC Centerless Grinding

CNC centerless grinding is a machining process that involves the removal of material from a workpiece using a grinding wheel, supplemented by a regulating wheel that controls the workpiece's rotation and position. Unlike traditional grinding methods, centerless grinding does not require a fixture or centre to hold the part. Instead, the workpiece is positioned between the grinding wheel and the regulating wheel, allowing for continuous production without the setup time required for conventional grinding processes.

This grinding technique is particularly effective for high-volume, precision parts, making it ideal for industries ranging from automotive to aerospace, medical devices, and general manufacturing. CNC technology enhances the process by allowing for programmed control of the grinding parameters, leading to higher productivity and less human error.

Key Components of CNC Centerless Grinders

1. Grinding Wheel The primary tool used for material removal. It is typically made from abrasive materials and can come in various shapes and sizes depending on the application. 2. Regulating Wheel This component controls the rotational speed and positioning of the workpiece, ensuring uniform grinding and reducing the risk of part slippage.

3. Workblade A rigid support that holds the workpiece in place, providing stability during grinding operations.

4. Computer Control System The brains of the operation, this system allows for precise programming of the grinding parameters, such as feed rates and wheel speeds, which can be adjusted to optimize the grinding process for different materials and geometries.

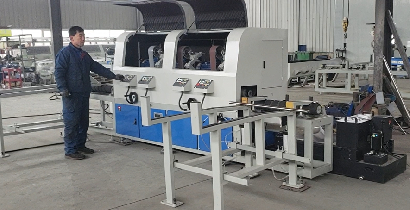

cnc centerless grinder products

Advantages of Using CNC Centerless Grinders

1. Increased Efficiency CNC centerless grinders allow for continuous operation, which minimizes downtime and maximizes productivity in manufacturing settings. This is crucial for high-volume production runs.

2. Higher Accuracy The automatic control of each grinding cycle reduces human error, resulting in tightly held tolerances and superior finish quality. This is essential for industries requiring stringent precision, such as aerospace or medical manufacturing.

3. Versatility CNC centerless grinders can handle a wide range of materials and part sizes, making them adaptable to various manufacturing processes. They can easily switch between different part types with minimal adjustments, which is beneficial in manufacturing environments with diverse product lines.

4. Cost Efficiency Although the initial investment in CNC technology can be high, the long-term savings through reduced labor costs, increased production rates, and lower scrap rates provide a strong return on investment.

5. Innovative Features Modern CNC centerless grinders often come equipped with advanced features like in-process gauging, automatic loading and unloading, and enhanced cooling systems, which further optimize the grinding process and improve overall machine reliability.

Conclusion

In conclusion, CNC centerless grinders are a core component of modern precision manufacturing. Their ability to grind cylindrical parts efficiently and accurately without the need for a fixed center enhances productivity and quality across various industries. As technology continues to advance, the integration of CNC systems into centerless grinding will likely evolve, further transforming manufacturing processes and leading to new applications and efficiencies. For companies committed to maintaining high standards of quality and efficiency, investing in CNC centerless grinding technology is an essential step toward meeting the demands of today’s competitive market.