The Importance of CNC Centerless Grinder Machines in Modern Manufacturing

In today's fast-paced manufacturing landscape, precision and efficiency are paramount. Among various machining technologies, CNC (Computer Numerical Control) centerless grinding machines stand out for their ability to produce high-quality components with minimal human intervention. This sophisticated technology not only streamlines the grinding process but also enhances productivity and accuracy, making it a crucial asset for manufacturers across multiple industries.

What is a CNC Centerless Grinder?

A CNC centerless grinder is a type of grinding machine that utilizes a centerless grinding process. Unlike traditional grinding machines where the workpiece is mounted between two centers, centerless grinders hold the workpiece in place using a support blade and the grinding wheel, which rotates around it. This method allows for continuous grinding without the need for the operator to reposition the workpiece, thus improving production rates.

Centerless grinding typically involves three main components the grinding wheel, the regulating wheel, and the workpiece. The grinding wheel is responsible for removing material from the workpiece, while the regulating wheel controls the speed of the workpiece and its axial position. Together, these components work in synergy to achieve precise dimensions and tolerances.

Advantages of CNC Centerless Grinding

1. High Precision One of the key benefits of CNC centerless grinders is their ability to deliver high precision and repeatability. The CNC control system enables meticulous adjustments in wheel speed, feed rates, and other parameters, providing manufacturers with tight tolerances that are often required in applications like automotive, aerospace, and medical manufacturing.

2. Enhanced Productivity The centerless grinding process allows for continuous operation, which minimizes downtime. Because workpieces do not require resetting or fetching for each cycle, manufacturers can achieve higher output levels. This continuous feed system makes CNC centerless grinding especially suitable for mass production environments.

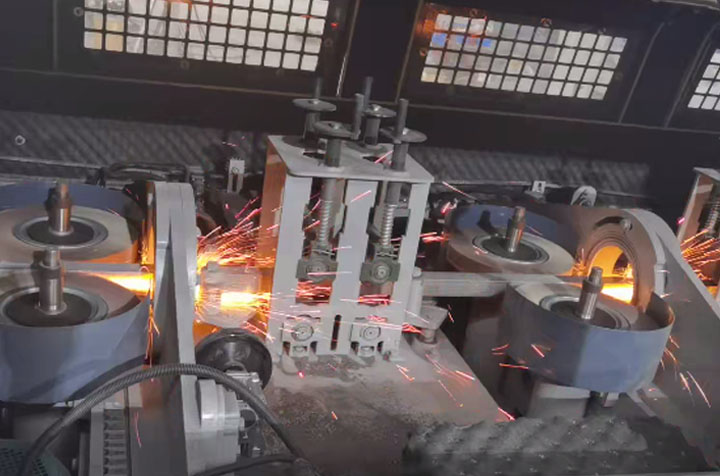

cnc centerless grinder machine

3. Versatility CNC centerless grinders can accommodate a wide range of workpiece materials and sizes. Whether it's grinding small, delicate components or larger, heavier parts, these machines can be customized to meet diverse machining needs. Additionally, CNC centerless grinders can easily adapt to various grinding operations, such as through-feed, in-feed, and end-feed grinding.

4. Reduced Labor Costs Automation through CNC technology significantly reduces the need for manual labor. Once programmed, CNC centerless grinders can operate independently, decreasing labor costs and allowing operators to focus on other essential tasks within the manufacturing process.

5. Improved Surface Finish The precision grinding capabilities of CNC centerless machines can yield exceptional surface finishes, which are crucial for components requiring smooth surfaces and minimal friction. This quality is particularly important in industries where high performance and durability are required.

Applications of CNC Centerless Grinders

CNC centerless grinders find applications in various sectors, including

- Automotive Industry They are used for grinding precision-engineered components, such as shafts, bearings, and fuel injectors. - Aerospace Manufacturing Components like landing gear and turbine blades require exact dimensions and surface finishes that centerless grinding can provide. - Medical Devices Many medical instruments and implants benefit from the high precision and biocompatibility achieved through centerless grinding. - Electrical Components The manufacturing of connectors and other small electronic components often utilizes centerless grinding for efficiency and precision.

Conclusion

CNC centerless grinder machines represent a revolution in the grinding process, providing manufacturers with unparalleled precision, efficiency, and versatility. As industries continue to demand higher quality and faster turnaround times, the role of CNC centerless grinders will undoubtedly become even more integral to the manufacturing ecosystem. By investing in this advanced technology, manufacturers can not only stay competitive but also drive innovation in their production processes, ensuring sustained success in the market. In a world where every second counts, CNC centerless grinding is poised to lead the way in modern manufacturing.