Centerless Grinders for Sale Enhancing Precision in Manufacturing

In the ever-evolving landscape of manufacturing, precision is of paramount importance. One of the essential machines that ensure this level of accuracy is the centerless grinder. Companies specializing in CNC (Computer Numerical Control) centerless grinders are revolutionizing the machining industry by offering advanced equipment capable of achieving high precision and efficiency. If you are in the market for a CNC centerless grinder, understanding its features, advantages, and application can aid in making an informed purchase.

What is a Centerless Grinder?

A centerless grinder is a type of grinding machine that does not require the workpiece to be mounted on a spindle or fixture. Instead, the workpiece is held between two rotary grinding wheels. This design allows for continuous grinding, making it an efficient and effective solution for machining cylindrical parts. The absence of a center mounting provides several advantages, including improved efficiency, reduced setup time, and the ability to produce parts with tighter tolerances.

Advantages of CNC Centerless Grinders

CNC centerless grinders offer significant advantages over traditional grinding methods. Here are some of their key benefits

1. Precision and Consistency CNC technology automates the grinding process, ensuring that each part is produced with high precision. This consistency is critical in industries where tolerances are strict, such as aerospace and automotive manufacturing.

2. Increased Productivity The automatic nature of CNC centerless grinders allows for faster production rates. These machines can operate continuously, minimizing downtime and maximizing output.

3. Flexibility Modern CNC centerless grinders are adaptable and can handle various materials and shapes with ease. This versatility makes them suitable for a wide range of applications, from medical devices to tooling components.

4. Reduced Labor Costs With automation and precision, the need for excessive manual labor is reduced. This not only cuts labor costs but also minimizes human error, leading to higher quality output.

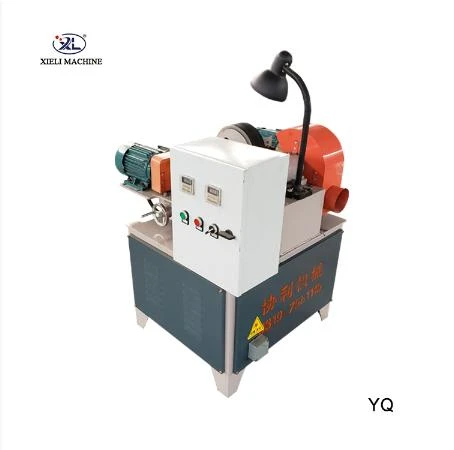

cnc centerless grinder for sale company

5. Enhanced Machining Capabilities CNC centerless grinders can perform various operations, such as in-feed grinding and through-feed grinding, making them valuable assets for manufacturers requiring different machining techniques.

Choosing the Right CNC Centerless Grinder

When searching for a CNC centerless grinder for sale, there are several factors to consider

1. Specifications Look for machines that fit your specific requirements in terms of size, capacity, and the types of materials you will be grinding.

2. Brand Reputation Opt for reputable manufacturers known for quality and reliability. Reading customer reviews and testimonials can provide valuable insights into the performance of different models.

3. After-Sales Support Ensure that the company offers comprehensive after-sales support, including maintenance, spare parts availability, and customer service.

4. Cost vs. Value While price is always a consideration, it is crucial to weigh the cost against the value and capabilities of the machine. Investing in a high-quality CNC centerless grinder can lead to long-term savings through enhanced productivity and reduced waste.

Conclusion

CNC centerless grinders are at the forefront of precision manufacturing, providing the efficiency and accuracy needed in today’s competitive market. By understanding the benefits and features of these machines, companies can make well-informed decisions when purchasing. Investing in a CNC centerless grinder will not only improve production processes but also ensure the quality and consistency of manufactured parts, ultimately contributing to a company’s success in the industry. As the market for CNC centerless grinders continues to grow, now is the perfect time to explore available options and take your manufacturing capabilities to the next level.