The Emergence and Impact of CNC Centerless Grinder Factories

In recent years, the manufacturing industry has experienced significant advancements, particularly in the realm of precision machining. One of the standout innovations within this sector is the Computer Numerical Control (CNC) centerless grinder. As industry demands grow for higher precision and efficiency, CNC centerless grinder factories have emerged as critical players in the production landscape.

The Emergence and Impact of CNC Centerless Grinder Factories

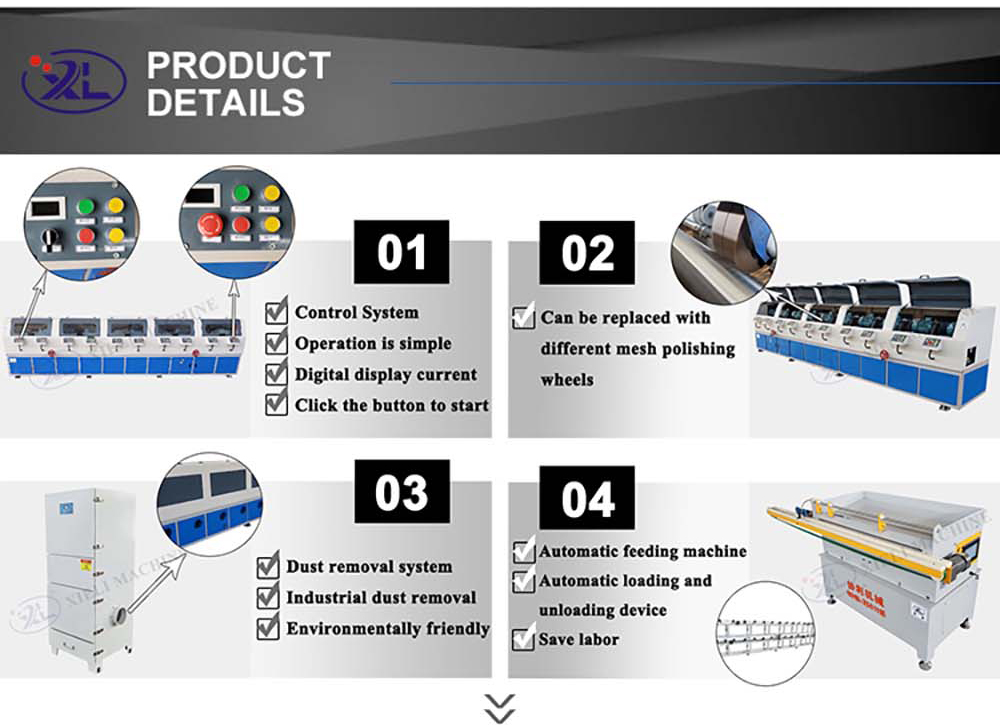

The rise of CNC technology has revolutionized the grinding process. CNC centerless grinder factories leverage sophisticated software to control the grinding process with incredible precision. This automation not only minimizes human error but also enhances repeatability — crucial factors in industries that demand strict adherence to specifications, such as the automotive, aerospace, and medical sectors. With the ability to program complex shapes and contours, manufacturers can achieve levels of accuracy that were previously unattainable with manual machining.

cnc centerless grinder factories

In the context of global manufacturing, the establishment of CNC centerless grinder factories has had far-reaching implications. These factories are often designed with advanced manufacturing principles in mind, incorporating lean manufacturing strategies to maximize efficiency and minimize waste. By utilizing high-speed grinding wheels and optimized tooling, they can produce parts more quickly while maintaining high levels of quality.

Moreover, the demand for CNC centerless grinders has prompted factories to continually innovate and improve their processes. These advancements include the integration of automation and robotic systems, which further enhance the speed and precision of operations. Additionally, the adoption of IoT (Internet of Things) technologies allows for real-time monitoring and data analytics. This helps manufacturers track performance metrics, predict maintenance needs, and ensure optimal machine utilization.

The proliferation of CNC centerless grinder factories also underscores the importance of skilled labor in the manufacturing sector. While automation plays a key role, the operation of CNC machines requires trained professionals who understand both the machinery and the underlying principles of machining. As a result, educational institutions and training programs have stepped up to prepare the next generation of machinists and engineers to meet industry needs.

In conclusion, the emergence of CNC centerless grinder factories marks a significant shift in the manufacturing landscape. By combining advanced technology and precision engineering, these facilities not only enhance production capabilities but also meet the stringent demands of modern industries. As technology continues to evolve, the role of these factories will likely expand, contributing to the ongoing transformation of manufacturing practices. As we look to the future, it is clear that CNC centerless grinders will remain at the forefront of innovation and efficiency in the machining world.