The Importance of Quality Parts in Centerless Grinding A Focus on Cinco 2015

Centerless grinding is a critical machining process widely used in manufacturing to produce high-precision cylindrical parts. Among the various players in the market, Cinco has established itself as a notable manufacturer of centerless grinders, particularly the model released in 2015. The quality and availability of replacement parts for such machines are crucial due to the rigorous demands of the grinding process. This article delves into the significance of sourcing quality parts for the Cinco 2015 centerless grinder and examines the factories that specialize in their production.

The Importance of Quality Parts in Centerless Grinding A Focus on Cinco 2015

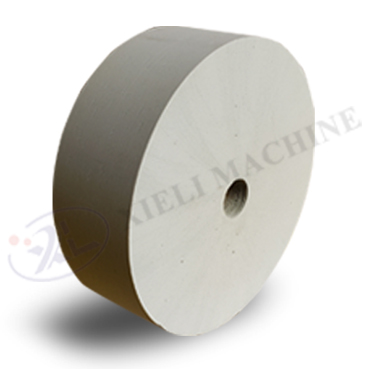

When discussing the parts for the Cinco 2015 centerless grinder, several components come to the forefront, including grinding wheels, regulating wheels, bearings, and drive mechanisms. Each of these parts plays a crucial role in the operation of the machine. For example, the grinding wheels must be made from high-quality materials that resist wear and tear while providing the precision needed to meet tight tolerances. Similarly, bearings that support the rotating parts must be of excellent quality to minimize friction and contribute to the smooth operation of the grinder.

cinco 15 centerless grinder parts factories

The factories that manufacture parts for the Cinco 2015 centerless grinder are equipped with advanced technology and skilled labor. These factories not only produce replacement parts but are also responsible for ensuring that these components meet stringent industry standards. Quality control processes are vital in these factories, as any deviation in part specifications can lead to issues such as uneven grinding, increased wear on the machine, and diminished quality of the finished products. Reputable manufacturers will often conduct regular audits and quality assessments to maintain the integrity of their production processes.

Another essential factor to consider is the availability of parts. In industries that rely on precision machining, the downtime resulting from equipment failures can be costly. Therefore, having reliable suppliers for the Cinco 2015 centerless grinder components is imperative. Factors such as lead time, inventory levels, and after-sales support are all critical when choosing a supplier. Factory partnerships that prioritize quick response times and a robust inventory of commonly used parts can significantly reduce downtime and improve operational efficiency.

Furthermore, advancements in technology have led to the incorporation of better materials and innovative manufacturing techniques that enhance the performance of grinding components. Factories are increasingly utilizing computer-aided design (CAD) and computer numerical control (CNC) machinery to produce precision parts that fit seamlessly with the original equipment. This level of innovation ensures that users of the Cinco 2015 centerless grinder can maintain optimal performance through the use of superior replacements.

In conclusion, the right parts are integral to the effective operation of the Cinco 2015 centerless grinder. Sourcing high-quality components from reputable factories not only preserves the integrity of the machine but also maximizes productivity and minimizes costs. As industries continue to evolve, the demand for precision in machining will only increase, making the quality of replacement parts an asset that manufacturers cannot afford to overlook. For operators of the Cinco 2015 centerless grinder, investing in quality components is a step towards sustaining operational excellence and achieving manufacturing goals.