The Advantages of Choosing a Cinco 2015 Centerless Grinder for Sale

In the realm of precision manufacturing, the significance of reliable equipment cannot be overstated. Among the critical tools used in the manufacturing process, centerless grinders play a vital role in enhancing production efficiency and ensuring high-quality output. One notable model that has gained attention in the industry is the Cinco 2015 Centerless Grinder. For companies seeking to optimize their production lines, purchasing a Cinco 2015 offers numerous advantages.

1. Enhanced Precision and Quality

The Cinco 2015 Centerless Grinder is designed to deliver exceptional precision in grinding operations. This model is engineered to meet the stringent tolerances required in various manufacturing processes. Whether it is for automotive components, medical devices, or aerospace parts, the precision of the Cinco grinder ensures that the finished products meet the highest quality standards. By investing in such a reliable machine, businesses can significantly reduce waste and rework, contributing to overall operational efficiency.

2. Increased Production Efficiency

One of the key benefits of the Cinco 2015 Centerless Grinder is its ability to streamline the manufacturing process. The machine allows for continuous operation with minimal downtime, which is essential for high-volume production. Its user-friendly interface and automated features enable operators to set up and adjust the machine quickly, reducing changeover times between jobs. This efficiency translates to shorter lead times, allowing companies to respond more swiftly to market demands and customer needs.

3. Versatility in Grinding Applications

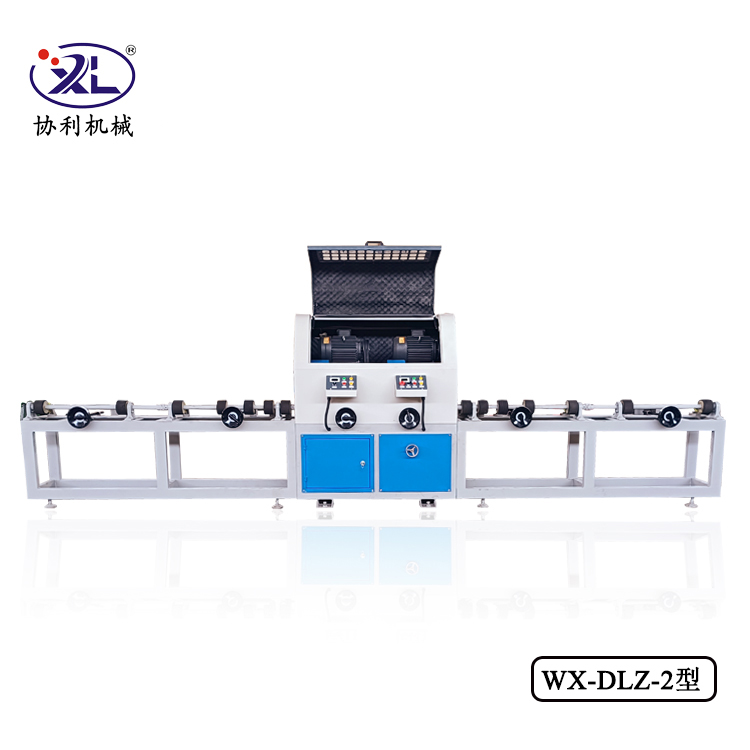

cinco 15 centerless grinder for sale company

The versatility of the Cinco 2015 Centerless Grinder makes it an ideal choice for a wide range of applications. This model can handle different materials and sizes, making it suitable for various industries. Whether you need to grind small, intricate components or larger parts, the Cinco grinder adapts easily to different requirements. This flexibility empowers companies to diversify their product offerings without the need for additional equipment, thus maximizing their return on investment.

4. Cost-Effective Solutions

When considering the purchase of a centerless grinder, cost-effectiveness is a crucial factor. The Cinco 2015 strikes a balance between affordability and high performance. With its durable construction and reliable components, this model minimizes maintenance costs and extends operational longevity. Additionally, the efficiency gains achieved through improved production processes can lead to significant cost savings over time, making the initial investment worthwhile.

5. Industry Reputation and Support

Cinco has established a strong reputation in the manufacturing industry for producing high-quality grinding equipment. Buyers of the 2015 Centerless Grinder can benefit from a wealth of knowledge and support from the company. This includes access to training resources, technical support, and a network of parts suppliers, ensuring that clients can maintain their machines effectively. Such support is invaluable in minimizing operational disruptions and maximizing machine uptime.

Conclusion

In conclusion, the Cinco 2015 Centerless Grinder is a compelling option for businesses looking to enhance their manufacturing capabilities. With its precision, efficiency, versatility, and cost-effectiveness, this model stands out in the competitive landscape of industrial equipment. As companies seek to innovate and improve their processes, investing in reliable machinery like the Cinco 2015 can provide a significant competitive edge, ultimately leading to increased productivity and profitability. For organizations committed to excellence in manufacturing, the Cinco 2015 Centerless Grinder is a smart choice that promises to deliver exceptional results.