Exploring the Market for Centerless Grinders The Case of the Cinco 2015 Model

In the manufacturing and machining industries, precision and efficiency are paramount. Among the essential tools that contribute to achieving these goals are centerless grinders. These machines play a crucial role in shaping and finishing metal components, enabling manufacturers to meet strict specifications and maintain high production rates. One model that has garnered attention in the market is the Cinco 2015 centerless grinder. In this article, we will explore the features of the Cinco 2015, its applications, and why it stands out in the competitive landscape of centerless grinders.

What Is a Centerless Grinder?

Before delving into the specifics of the Cinco 2015, it is important to understand what a centerless grinder does. Unlike traditional cylindrical grinders that require the workpiece to be mounted between centers, centerless grinders support the workpiece using a system of wheels and rollers. This design allows for continuous production of parts without the need for repositioning, enabling manufacturers to achieve higher efficiency and throughput.

Centerless grinding is commonly used for processing cylindrical parts, including rods, shafts, pins, and various other components. The ability to grind workpieces without any centering device eliminates the need for elaborate setups, making it a preferred choice in many production environments.

Features of the Cinco 2015 Centerless Grinder

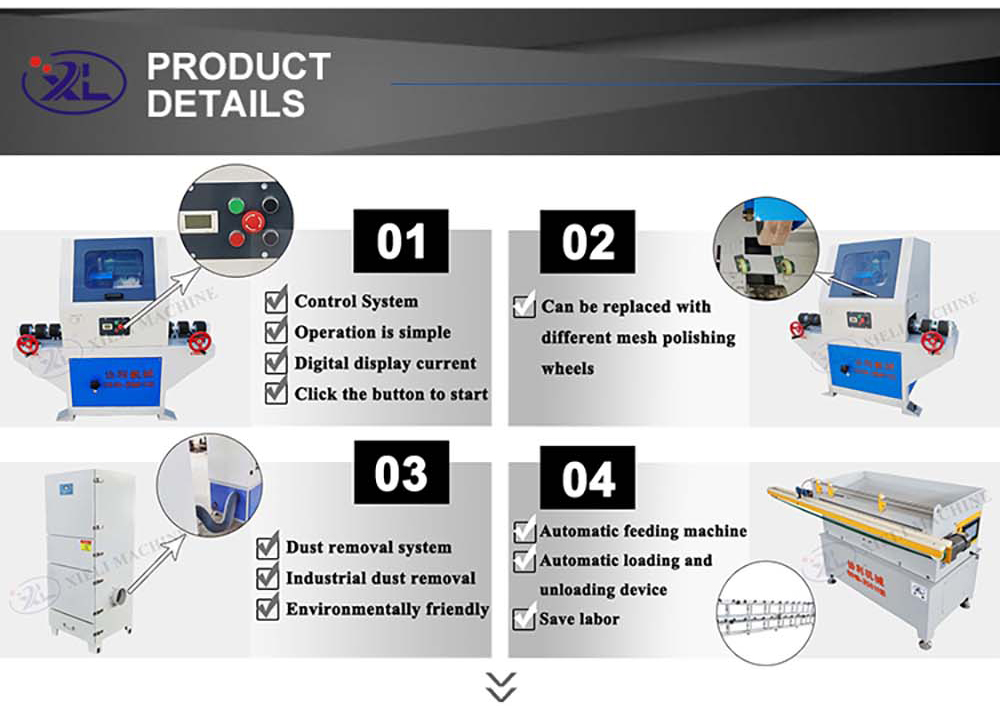

The Cinco 2015 centerless grinder is designed with advanced technology to optimize performance and efficiency. Some of its key features include

1. Precision Grinding Capabilities The Cinco 2015 provides high precision in grinding operations. Its design enables the production of tightly toleranced parts, which is essential for industries that require strict adherence to specifications, such as aerospace and automotive.

2. User-Friendly Controls Equipped with intuitive controls, the Cinco 2015 allows operators to easily set up and adjust grinding parameters. This user-friendly interface ensures that operators can quickly learn how to operate the machine, reducing the training time and enhancing productivity.

cinco 15 centerless grinder for sale company

3. Robust Construction The durability of the Cinco 2015 is one of its standout features. Built with high-quality materials, this grinder is designed to withstand the rigors of continuous operation. Its sturdy construction minimizes vibrations, leading to better surface finishes and extended tool life.

4. Versatility The Cinco 2015 is suitable for grinding a wide variety of materials, including hardened steel, aluminum, and other alloys. Its versatility makes it an attractive option for job shops and manufacturers who work with different materials and components.

5. Enhanced Automation Options As automation becomes increasingly important in manufacturing, the Cinco 2015 offers customizable automation options. This feature allows companies to integrate the grinder into automated production lines, enhancing efficiency and reducing manual labor.

Market Position and Applications

The Cinco 2015 centerless grinder is well-positioned in the market due to its combination of advanced features, reliability, and versatility. It appeals to many industries, including automotive, aerospace, medical devices, and general manufacturing. Companies looking to enhance their production capabilities often consider investing in the Cinco 2015 as it helps reduce processing times while maintaining quality.

In addition, as manufacturers increasingly focus on lean production and waste reduction, the centerless grinding process offered by the Cinco 2015 aligns perfectly with these goals. By minimizing setup times and maximizing throughput, companies can achieve greater flexibility and responsiveness to market demands.

Conclusion

The Cinco 2015 centerless grinder exemplifies the innovation and efficiency that modern manufacturing requires. Its features, including precision capabilities, user-friendly controls, and robust construction, make it a top choice for businesses seeking to enhance their machining processes. As the demand for high-quality ground components continues to rise, investing in state-of-the-art machinery like the Cinco 2015 could be a game-changer for manufacturers aiming to stay competitive in a challenging marketplace. Whether for small job shops or large-scale manufacturers, the Cinco 2015 is a solution worth considering for anyone in need of reliable centerless grinding capabilities.