Navigating the world of precision machinery, the Cincinnati serial number centerless grinder has emerged as a leading choice for industry experts who value performance and precision. For decades, Cincinnati centerless grinders have been synonymous with state-of-the-art innovation and unparalleled quality in the grinding industry.

Renowned for their precision engineering, these machines boast a legacy that intertwines masterful craftsmanship with advanced technology. The foundation of their success stems from an ongoing commitment to innovation and improvement, driven by real-world experiences from users across various industries. As such, Cincinnati grinders have consistently evolved, meeting the ever-changing needs of modern manufacturing environments.

One of the standout features of the Cincinnati serial number centerless grinder is its ability to perform consistent and high-quality finishing operations. These machines are meticulously designed to accommodate a wide range of grinding applications, which include everything from small batch production to large-scale, high-volume manufacturing processes. Their versatility is a testament to Cincinnati's expertise in understanding the intricate demands of different industrial sectors.

Central to the draw of Cincinnati grinders is their cutting-edge three-point positioning system. This system ensures optimal stability and consistency during the grinding process, minimizing deviations and delivering superior finish quality. Notably, this feature represents a fusion of traditional engineering principles and modern technological advancements, underscoring Cincinnati's authoritative command in the grinding domain.

Users also benefit from intuitive controls and customizable settings, allowing for seamless integration into existing workflows. This adaptability not only enhances productivity but also reduces setup times, thereby promoting operational efficiency. These elements collectively make Cincinnati centerless grinders a trusted asset in achieving competitive edge in the field of precision machining.

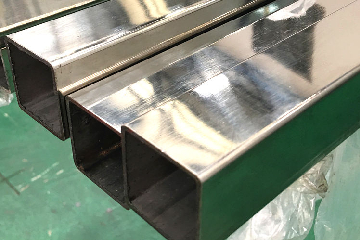

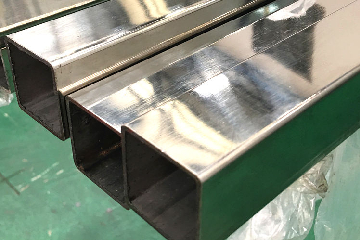

cincinnati serial number centerless grinder product

Investing in a Cincinnati centerless grinder means investing in the credibility that comes with the brand’s longstanding history of reliability. The trustworthiness of these machines is further augmented by Cincinnati's comprehensive support network, which provides expert guidance and solutions to maximize machine performance. This ensures that businesses can rely on continuous, high-quality output while minimizing downtime.

Furthermore, the documentation associated with the serial numbers of Cincinnati grinders enables a precise tracking mechanism for maintenance and part replacements. This serial number system empowers users by providing access to detailed machine histories, contributing to prolonged machine life and sustained production excellence.

Real-world experience from long-term users highlights the durability and resilience of Cincinnati centerless grinders. Time and again, these machines have demonstrated their ability to operate under demanding conditions without compromising on the quality of output. This durability reflects a deep understanding of material properties and mechanical engineering, which Cincinnati has honed over years of dedicated research and development.

In terms of expertise, Cincinnati's continuous engagement with leading engineers and industry specialists ensures that their grinders meet the highest standards of precision and performance. This collaborative approach not only fuels innovation but also fortifies the grinders’ status as industry benchmarks for accuracy and efficiency.

In conclusion,

the Cincinnati serial number centerless grinder encompasses a blend of experience, expertise, authoritativeness, and trustworthiness. It stands as a testament to Cincinnati’s commitment to delivering machines that embody technical excellence and unrivaled reliability. For manufacturers seeking to elevate their production capabilities, Cincinnati centerless grinders offer not just a tool, but a transformative experience that enhances both quality and efficiency in the competitive landscape of modern manufacturing.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.