The Rise of Cincinnati Centerless Grinder Remanufacturing Factories

Cincinnati, Ohio, has long been a hub for manufacturing, particularly in the field of precision machinery. Among the city's specialties are centerless grinders, machines that are crucial for the production of cylindrical parts. However, as industries evolve, the demand for these machines has led to a growing trend the remanufacturing of centerless grinders. This process not only extends the life of these essential tools but also aligns with modern sustainability goals.

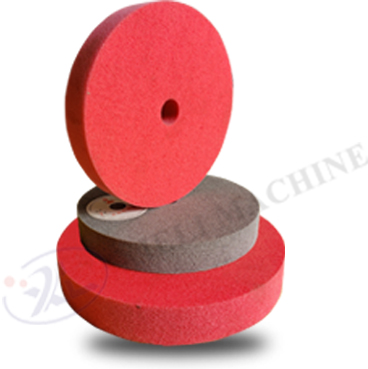

Understanding Centerless Grinding

Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece. Unlike traditional grinding, where the part is supported by centers, centerless grinding involves the workpiece being situated between two wheels the grinding wheel and the regulating wheel. This method allows for high-accuracy production of cylindrical shapes with superior surface finishes. Industries ranging from automotive to aerospace rely heavily on this technology because of its efficiency and ability to produce parts at scale.

The Need for Remanufacturing

While brand new machines can be quite expensive, remanufacturing offers a cost-effective alternative for companies looking to enhance their production capabilities. When a centerless grinder experiences wear and tear, rather than purchasing a new model, many businesses opt to remanufacture their existing equipment. This involves disassembling the machine, replacing or refurbishing worn components, and reassembling it to meet or exceed original specifications.

The remanufacturing process offers several advantages

1. Cost Savings Remanufactured machines can save companies up to 50% of the cost of buying new equipment. 2. Quality Assurance Reputable remanufacturing factories rigorously test and certify their machines, ensuring they perform at optimal levels. 3. Environmental Impact By extending the life of existing machines, remanufacturing reduces waste and the carbon footprint associated with manufacturing new equipment.

cincinnati centerless grinder remanufacturing factories

Cincinnati’s Remanufacturing Landscape

Cincinnati’s remanufacturing factories have embraced this trend, investing in advanced technologies and skilled labor to enhance their processes. These facilities not only service local industries but also cater to a global market, exporting remanufactured machinery to various countries.

One notable aspect of Cincinnati’s remanufacturing sector is its focus on innovation. Companies are utilizing modern diagnostic tools and techniques, such as computer-aided design (CAD) and advanced materials, to improve the performance and durability of remanufactured grinders. This commitment to quality and innovation ensures that their machines remain competitive in the face of rapidly advancing technologies.

Challenges and Future Directions

Despite the clear benefits, the remanufacturing industry faces challenges. Competition from lower-cost manufacturers in developing countries complicates pricing strategies, and ensuring a consistent supply of skilled labor is increasingly difficult. Moreover, as industries embrace automation and Industry 4.0 principles, remanufacturers must adapt and invest in new technologies to stay relevant.

Looking forward, the Cincinnati remanufacturing sector is well-positioned to leverage emerging trends such as artificial intelligence and machine learning. By integrating these technologies into the remanufacturing process, factories can enhance predictive maintenance models and improve efficiency, thereby delivering even more value to their clients.

Conclusion

Cincinnati’s centerless grinder remanufacturing factories exemplify the ingenuity and resilience of the American manufacturing landscape. As businesses continue to seek cost-effective, high-quality solutions for their production needs, the importance of remanufacturing will undoubtedly grow. With a commitment to sustainability, innovation, and quality, Cincinnati stands as a leader in this field, ready to meet the challenges of the 21st century head-on.