Cincinnati Centerless Grinder Parts Manufacturers Ensuring Precision in Grinding Technology

In the realm of industrial manufacturing, precision is paramount, particularly when it comes to machining processes. Centerless grinding stands out as one of the most efficient methods for shaping and finishing cylindrical parts, making it an essential technique across various industries. Among the leaders in this field are the Cincinnati Centerless Grinders, known for their robust design, durability, and precision. However, the effectiveness of these grinders relies significantly on the availability, quality, and compatibility of their parts. This article explores the significance of Cincinnati centerless grinder parts manufacturers and the critical role they play in maintaining and enhancing grinding operations.

The Importance of Centerless Grinding

Centerless grinding is a process that allows for the continuous round parts to be ground without the need for a spindle or fixture. This method offers several advantages, including high production rates, minimal setup time, and the ability to grind multiple pieces simultaneously. It is particularly useful in industries that demand high volume and tight tolerances, such as automotive, aerospace, and medical device manufacturing.

Role of Parts Manufacturers

Cincinnati centerless grinder parts manufacturers are crucial in ensuring that these grinding systems operate at peak efficiency. They produce a wide range of components that are integral to the machine's function, including

- Grinding Wheels These are perhaps the most critical components of any grinder. The right grinding wheel can significantly affect the finish and precision of the workpiece. Manufacturers provide various specifications of grinding wheels, tailored to different materials and applications.

- Spindles A spindle's precision affects the performance of the grinder. High-quality spindles are essential for maintaining accuracy in the grinding process and sustaining machine longevity.

- Hydraulic Cylinders Many centerless grinders use hydraulic systems to control various functions, including the feeding and clamping of the workpieces

. Reliable hydraulic cylinders are essential to prevent leaks and maintain consistent pressure during operation.- Dressers Regular dressing of the grinding wheels ensures consistent performance and prolongs their lifespan. Manufacturers produce diamond dressers that meet specific standards for precision grinding.

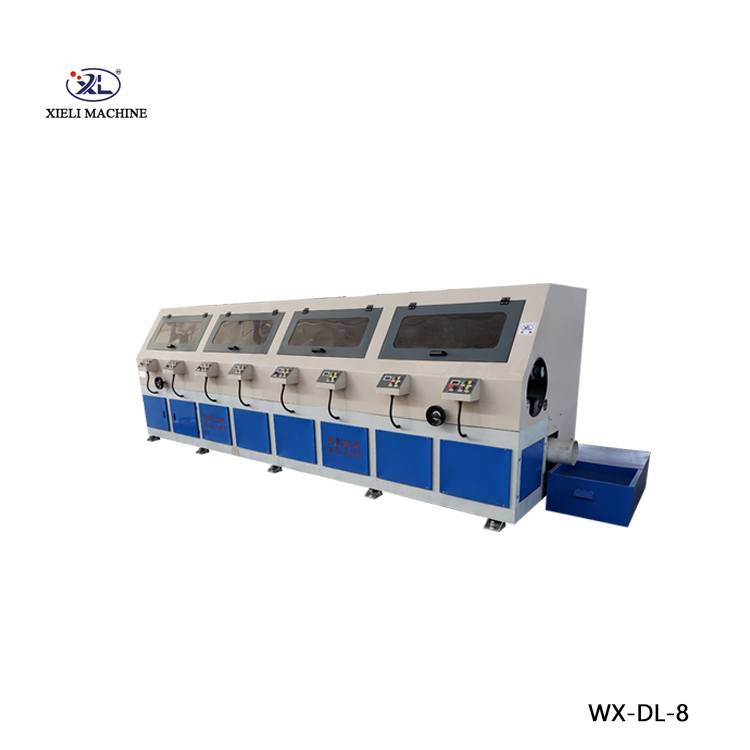

cincinnati centerless grinder parts manufacturers

- Control Systems Modern centerless grinders may be equipped with sophisticated control systems that facilitate automation and ensure high levels of repeatability. Parts manufacturers develop and supply electronic components that support these advanced functions.

Quality and Compatibility

One of the primary challenges faced by manufacturers and users of Cincinnati centerless grinders is ensuring that replacement parts maintain the same quality and compatibility as the original components. Reliability in quality control processes is crucial. Parts manufacturers must adhere to stringent specifications to meet industry standards.

Furthermore, given the wide variety of grinder models produced by Cincinnati, it’s crucial that parts manufacturers are well-versed in the specifications of different models. They need to provide parts that not only fit perfectly but also contribute to the machine’s overall performance. This understanding of the nuances of different models allows manufacturers to deliver tailored solutions that enhance operational efficiency.

The Future of Centerless Grinding Parts Manufacturing

As manufacturing technologies evolve, so too do the requirements for grinder parts. The advent of advanced materials and coatings, as well as automation and smart technologies, is shaping the future of centerless grinding. Parts manufacturers are increasingly focusing on integrating smart technologies into their components to enhance machine monitoring and performance.

Additionally, sustainability is becoming a more prominent consideration. Manufacturers are exploring eco-friendly materials and production methods to minimize waste and reduce their environmental footprint. This shift is not only beneficial for the planet but also aligns with the growing demand from stakeholders for sustainable practices in manufacturing.

Conclusion

Cincinnati centerless grinder parts manufacturers play a vital role in the grinding industry, contributing to the efficiency and precision of machining processes. With their commitment to quality, compatibility, and innovation, they ensure that manufacturers can maintain their centerless grinding operations at peak performance. As technology continues to advance, these manufacturers will be pivotal in shaping the future of precision grinding, ensuring that industries can meet the increasing demands for accuracy, efficiency, and sustainability. The relationship between machine manufacturers and parts suppliers is one that must be nurtured to ensure continual improvements and the success of modern manufacturing endeavors.