The Cincinnati centerless grinder machine stands as a testament to innovation and precision in the world of industrial grinding. This tool has revolutionized the manufacturing process, offering unparalleled efficiency and accuracy. For businesses in need of precision components, understanding the distinct advantages of Cincinnati centerless grinders is crucial—not only for operational excellence but also for maintaining a competitive edge in the market.

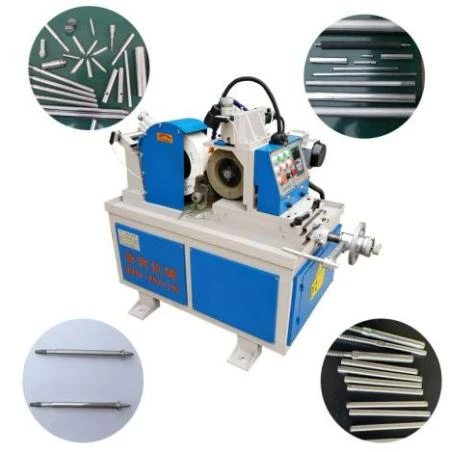

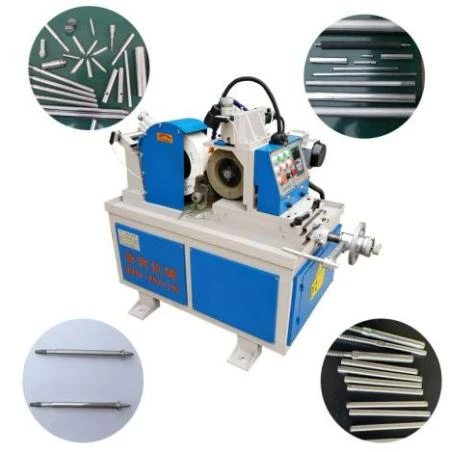

Centerless grinding, as opposed to traditional cylindrical grinders, eliminates the need for a workpiece to be held in place. Instead, the workpiece is positioned between a grinding wheel and a regulating wheel. The efficiency and capabilities of this configuration enable high-throughput operations, making the Cincinnati centerless grinder machine an optimal choice for mass production environments.

Expert users of Cincinnati centerless grinders often boast about the machines' ability to produce high volumes of precision parts without the necessity for extensive setup or fine-tuning between jobs. The machine’s capacity to grind parts without requiring additional fixtures makes it an asset in environments that demand adaptability and efficiency. With fewer hardware adjustments necessary, operators can transition between different specifications seamlessly, thus conserving valuable production time.

What sets the Cincinnati machines apart is their robust build quality and the ability to customize the grinding process according to precise specifications. Cincinnati grinders incorporate advanced control systems that allow operators to adjust the speed and pressure applied by the grinding wheels, customizing each aspect of the grinding process to achieve the desired finish and dimensional accuracy. This level of control ensures that operators can achieve mirror finishes or specific surface roughness, determined by the component's end-use. Industries ranging from aerospace to automotive heavily rely on this feature to adhere to stringent component specifications and quality standards.

Authoritativeness in the field of centerless grinding is particularly evident in Cincinnati’s commitment to technological advancement. The introduction of automation capabilities into their machines underscores their forward-thinking approach. By integrating robotic arms for part loading and unloading, Cincinnati has reduced manual intervention, which in turn minimizes human error and leads to increased repeatability across production batches. Automated cycle optimizations further enhance efficiency by reducing idle times and ensuring that each part is processed within optimal timelines without sacrificing quality.

cincinnati centerless grinder machine quotes

Trustworthiness is another cornerstone of Cincinnati’s market reputation. The machines are designed for durability and sustained high performance. Routine maintenance procedures are simplified, which increases reliability and longevity—key concerns for any production facility. Many satisfied operators note the longevity of Cincinnati machines, often exceeding expected service life while maintaining peak operational performance.

Moreover, the Cincinnati centerless grinder machine fulfills various compliance standards, an essential factor for industries where certifications determine market access. Their adherence to stringent quality and safety certifications ensures that operations remain compliant with international norms, providing peace of mind to businesses looking to expand their market presence globally.

In terms of real-world applications, experienced machinists frequently report that Cincinnati centerless grinders excel when tasked with producing precision shafts, bearings, and other cylindrical components. The machines’ capability to maintain tight tolerances ensures that each produced part upholds the strict requirements of industries where precision is not just a preference but a necessity.

In conclusion, for manufacturers considering investment in new grinding technology, Cincinnati centerless grinder machines should undoubtedly be top of mind. They provide a reliable, versatile, and high-performance solution. Businesses that prioritize product quality and operational efficiency will find these machines indispensable. From their robust design and precise grinding capabilities to technological advancements and compliance with safety standards, Cincinnati centerless grinders not only fulfill but often exceed industry expectations, establishing themselves as leaders in the market.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.