Cincinnati Centerless Grinder A Comprehensive Overview for Buyers

The Cincinnati centerless grinder has been a cornerstone in the manufacturing industry for decades, known for its precision and efficiency. If you are considering purchasing a Cincinnati centerless grinder, whether for new projects or to enhance your existing production line, understanding the features, benefits, and manufacturers is essential. This article provides a detailed overview of Cincinnati centerless grinders, their applications, and what to consider when looking for the right machine.

What is a Centerless Grinder?

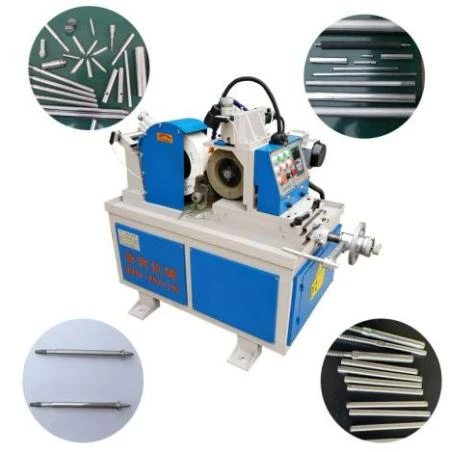

A centerless grinder is a type of grinding machine that uses a grinding wheel and a regulating wheel to perform precision grinding on cylindrical workpieces. Unlike traditional grinders, centerless grinders allow for continuous production of parts without the need for manual repositioning. This makes them ideal for high-volume manufacturing where speed and accuracy are critical.

The Advantage of Cincinnati Centerless Grinders

Cincinnati Grinders, a prominent name in the machinery sector, offers a range of centerless grinders that provide several advantages

1. Precision and Repeatability Cincinnati centerless grinders are engineered to achieve tight tolerances with a high degree of repeatability, making them perfect for industries such as automotive, aerospace, and medical device manufacturing.

2. Versatility These grinders can accommodate a variety of materials and workpiece sizes. Whether you are grinding steel, aluminum, or plastic, a Cincinnati centerless grinder can be customized to suit your specific needs.

3. Efficiency Centerless grinding minimizes downtime. The continuous feed and easy loading of parts enhance productivity, making it a savvy investment for any manufacturing operation.

Key Features to Look For

cincinnati centerless grinder for sale manufacturers

When shopping for a Cincinnati centerless grinder, consider the following features

- Wheel Diameter and Width Depending on your specific application, the diameter and width of the grinding wheel can significantly affect the grinding process.

- Regulating Wheel Adjustment Look for models that offer easy adjustments to the regulating wheel. This feature is vital for achieving accurate dimensions and can influence the overall speed of production.

- Infeed and Thrufeed Options Cincinnati centerless grinders typically offer both infeed and thrufeed mechanisms. Infeed grinding is suited for parts requiring a machining step in the middle of the cylinder, while thrufeed grinding is more efficient for longer parts.

- Control Systems Advanced control systems that facilitate easy operation and monitoring can enhance productivity. Options include CNC controls that allow for programmable settings and greater automation.

Finding Manufacturers and For Sale Listings

If you're in the market for a Cincinnati centerless grinder, it is critical to source machinery from reputable manufacturers. Established companies with decades of experience not only produce high-quality equipment but often offer reliable customer support and service.

Start your search by visiting industry-specific websites and marketplaces. Online platforms such as eBay, TradeMachines, or Machinery Network can provide listings of Cincinnati centerless grinders for sale, both new and refurbished. Attending trade shows and exhibitions, such as IMTS (International Manufacturing Technology Show), can also present opportunities to see equipment in action and connect with manufacturers.

Final Thoughts

Acquiring a Cincinnati centerless grinder can greatly enhance your manufacturing capabilities. By focusing on the precision, efficiency, and durability that these machines offer, you set your production line up for success. Whether increasing throughput or improving part accuracy, investing in the right centerless grinder is a strategic move. Ensure you conduct thorough research and make informed decisions to find the best machinery that suits your operational needs. With the information provided in this article, you are now better equipped to navigate the exciting landscape of centerless grinding machinery.