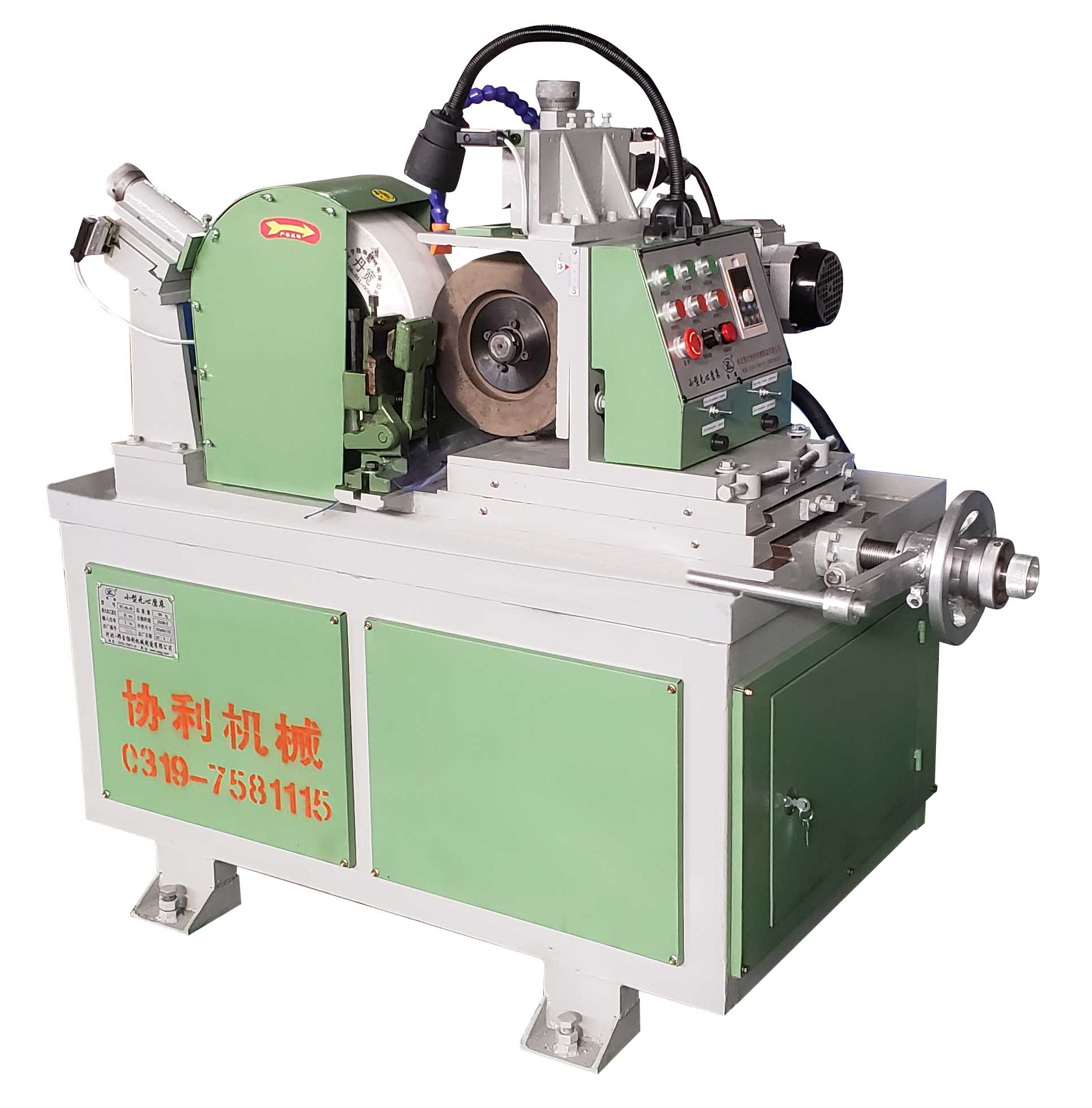

The Cincinnati Centerless Grinder 340-20 A Benchmark in Precision Engineering

The Cincinnati Centerless Grinder 340-20 is a key player in the realm of manufacturing and precision engineering

. Known for its robust design and exceptional grinding capabilities, this machine has become an indispensable tool for industries that prioritize accuracy and efficiency in their production processes.Centerless grinding has revolutionized the manufacturing landscape by providing a process that does not require the workpiece to be held in a fixture as is customary in traditional grinding methods. Instead, the Cincinnati 340-20 employs a unique mechanism that enables the grinding wheel to contact the part material directly, allowing for greater efficiency and speed in producing cylindrical parts. This innovation reduces setup time and enhances productivity, making it a favored choice among manufacturers seeking to optimize their operational capabilities.

One of the standout features of the Cincinnati Centerless Grinder 340-20 is its ability to grind materials to extremely tight tolerances. This precision is crucial in sectors such as aerospace, automotive, and medical device manufacturing, where minute deviations can lead to significant performance issues or even catastrophic failures. The machine's design minimizes vibrations, ensuring a smooth grinding operation that contributes to the consistency of the final product.

cincinnati centerless grinder 340-20 exporter

Moreover, the 340-20 model is celebrated for its user-friendly operation. The intuitive controls and well-laid-out interface allow operators to adjust settings easily, making the transitioning between different grinding tasks smoother and less time-consuming. This adaptability is essential for businesses that manage various projects with differing specifications, as it provides flexibility without compromising quality.

In the realm of maintenance, the Cincinnati Centerless Grinder 340-20 shines with its straightforward upkeep requirements. Routine maintenance procedures are simplified, which reduces downtime and enhances the overall lifespan of the grinder. This reliability translates to a more consistent output and reduced costs associated with machine failures and repairs.

Exporting the Cincinnati Centerless Grinder 340-20 to international markets represents a significant opportunity for manufacturers worldwide. As industries seek to enhance their manufacturing processes, the demand for high-quality, efficient grinding machines continues to grow. This demand creates an avenue for exporting not only the machine itself but also the associated knowledge and expertise in operating and maintaining such precision equipment effectively.

In conclusion, the Cincinnati Centerless Grinder 340-20 stands as a testament to advanced engineering and manufacturing excellence. Its combination of precision, efficiency, and user-friendly operation makes it an ideal solution for companies aiming to improve their grinding processes. As industries across the globe adopt centerless grinding techniques, the market for the Cincinnati 340-20 looks set to expand, signaling a promising future for both manufacturers and exporters alike. By leveraging the benefits of this state-of-the-art machine, businesses can elevate their production standards and remain competitive in an ever-evolving global marketplace.