Cincinnati 2 Centerless Grinder A Marvel of Precision Engineering

The Cincinnati 2 Centerless Grinder is a notable piece of machinery in the world of manufacturing and precision engineering. Renowned for its ability to deliver accurate and efficient grinding, this equipment has been a staple in various industries, including automotive, aerospace, and general manufacturing. Its design and functionality reflect years of innovation and a commitment to high standards in machining processes.

At the core of the Cincinnati 2's appeal is its centerless grinding principle. Unlike traditional grinding machines that require the workpiece to be held in place by chucks or fixtures, a centerless grinder uses a unique setup where the workpiece is placed between two grinding wheels — the grinding wheel and the regulating wheel. This configuration allows for continuous operation, facilitating a higher throughput compared to conventional grinding methods.

One of the standout features of the Cincinnati 2 is its versatility. It can accommodate various workpiece sizes and materials, ranging from small shafts to larger components. The grinding process is easily adjustable, allowing operators to change settings to suit different tasks, whether it’s for fine finishing or heavy stock removal. This adaptability makes it an invaluable tool in any fabrication shop.

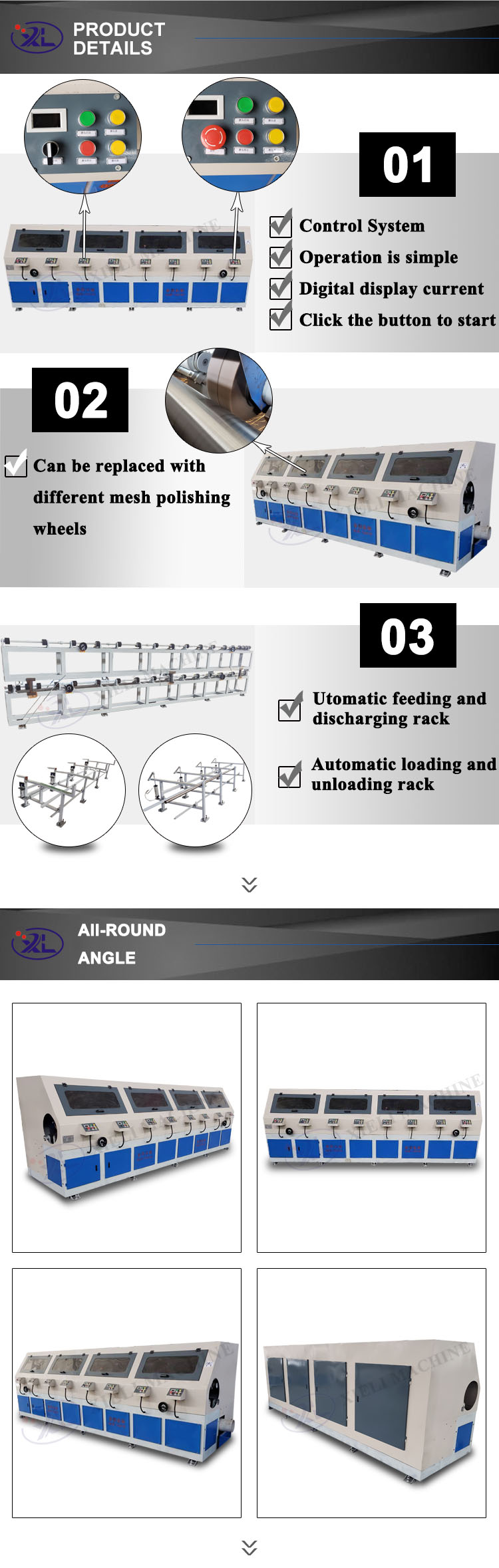

cincinnati 2 centerless grinder product

In terms of performance, the Cincinnati 2 is engineered for precision. The design minimizes vibration and ensures a stable platform for accurate grinding operations. Its robust build quality allows it to handle demanding workloads without compromising quality. Additionally, the machine is equipped with advanced controls that facilitate operator input and monitoring, ensuring that each grinding operation meets stringent tolerances.

Maintenance and durability are key considerations in any industrial machinery, and the Cincinnati 2 does not disappoint. Built with high-quality materials, this grinder boasts longevity, reducing the need for frequent repairs or replacements. This efficiency translates into cost savings over time, making it a smart investment for businesses looking to enhance their productivity.

Ease of operation is another hallmark of the Cincinnati 2 Centerless Grinder. Designed with the user in mind, it features intuitive controls and an ergonomic setup that minimizes operator fatigue. This design intention allows operators to achieve high levels of productivity while reducing the risk of error, contributing to superior output quality.

In conclusion, the Cincinnati 2 Centerless Grinder represents a significant advancement in grinding technology. With its precision, versatility, and user-friendly design, it has carved out a reputation as a reliable workhorse in the manufacturing sector. As industries continue to evolve, the need for high-precision grinding will remain, and the Cincinnati 2 will undoubtedly continue to play a crucial role in meeting these demands. Investing in such machinery not only enhances operational efficiency but also ensures that businesses remain competitive in an ever-changing market landscape. Whether you’re a large manufacturing plant or a small machine shop, the Cincinnati 2 Centerless Grinder stands out as a benchmark of quality and reliability in the grinding process.