Cincinnati 220-8 Centerless Grinder Service Ensuring Precision and Efficiency

The Cincinnati 220-8 Centerless Grinder is a highly regarded piece of machinery renowned for its precision and efficiency in manufacturing and metalworking processes

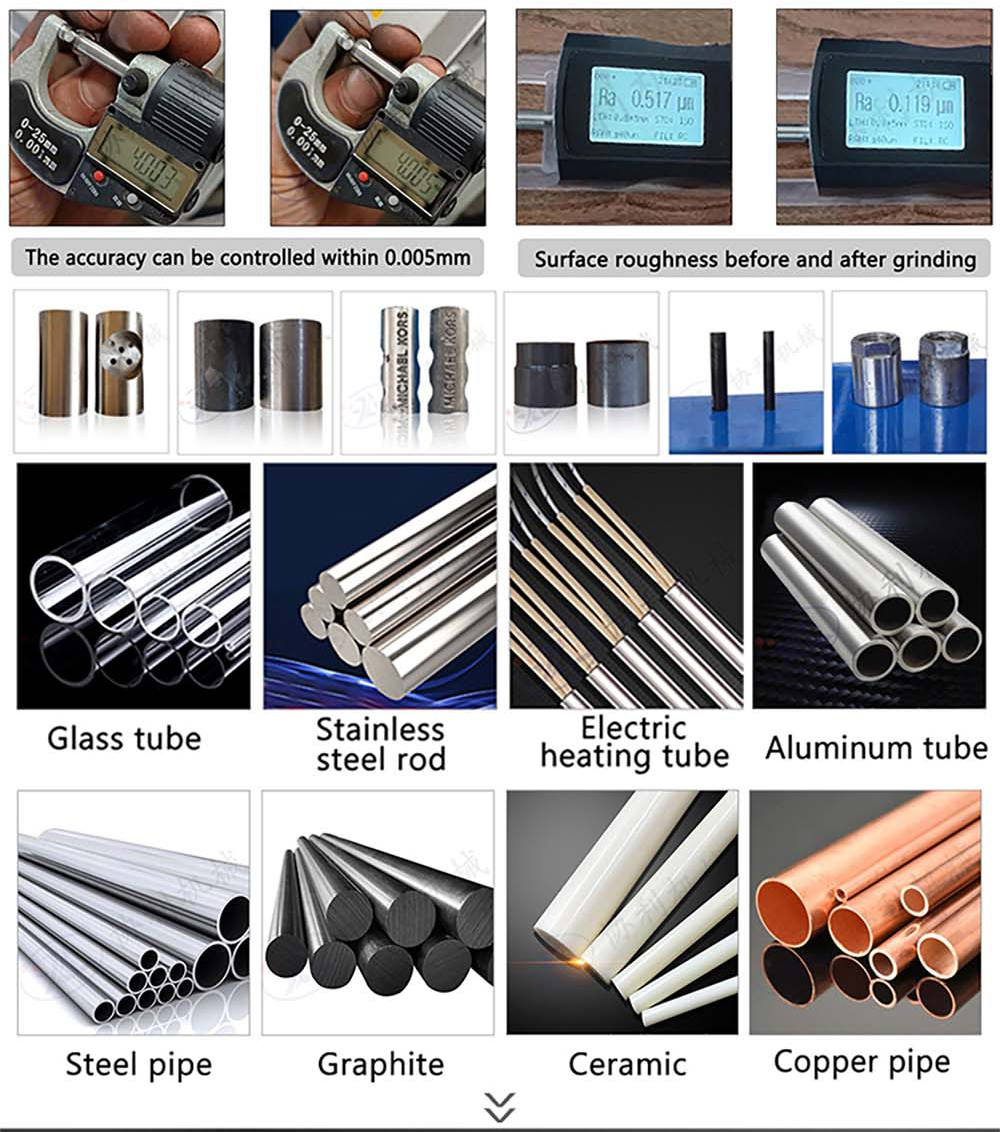

. As industries strive for greater productivity and optimal results, maintaining this iconic equipment becomes paramount. Regular service and maintenance not only prolong the machine's lifespan but also ensure that it operates at peak performance.Centerless grinding is a unique process that differs significantly from traditional grinding methods. In a centerless grinder, the part being machined is supported by a regulating wheel, which allows for high-speed operations without the need for additional clamping mechanisms. The Cincinnati 220-8 model epitomizes this technique, catering to a diverse range of applications, from automotive components to aerospace fittings.

To keep a Cincinnati 220-8 functioning flawlessly, it is essential to adhere to a rigorous maintenance schedule. Routine services should include inspection of critical parts such as the spindle, bearings, and grinding wheels. Proper alignment and adjustments are crucial for sustaining the tolerance levels that the industry demands. Additionally, regular cleaning and lubrication will mitigate wear and tear, ensuring that the machinery remains reliable over time.

cincinnati 220 8 centerless grinder service

One of the primary advantages of the Cincinnati 220-8 is its versatility. It can grind various materials and complex shapes with remarkable precision. However, any inconsistencies in the grinding process can lead to defects in the finished product, which ultimately affects overall productivity and profitability. Thus, timely servicing is indispensable in mitigating potential challenges that could impede operations.

Finding qualified technicians who specialize in Cincinnati centerless grinder services is crucial. Experienced professionals can conduct in-depth inspections, provide expert advice on parts replacement, and execute repairs with precision. Furthermore, they can offer training sessions to operators, ensuring that they are up-to-date on best practices for machine operation and maintenance.

In conclusion, the Cincinnati 220-8 Centerless Grinder is a vital asset for many manufacturing facilities. Regular service and maintenance are essential to keep this equipment operating at optimal levels. By prioritizing a proactive maintenance approach and relying on skilled technicians, businesses can enhance their production efficiency, reduce downtime, and ultimately maintain the high standards of quality that their customers expect. Investing in the care of such sophisticated machinery is not just a necessity; it's a strategic move toward sustained success in a competitive landscape.