The Cincinnati Centerless Grinder A Vital Tool for Precision Manufacturing

In the realm of precision manufacturing, the tools and equipment utilized can significantly influence the outcome of production processes. Among these essential machines, the Cincinnati centerless grinder stands out as a vital asset for manufacturers seeking to achieve high levels of accuracy and efficiency in their operations. Renowned for its robust construction and innovative design, the Cincinnati centerless grinder is a preferred choice among various industries, including automotive, aerospace, and medical device manufacturing.

Understanding Centerless Grinding

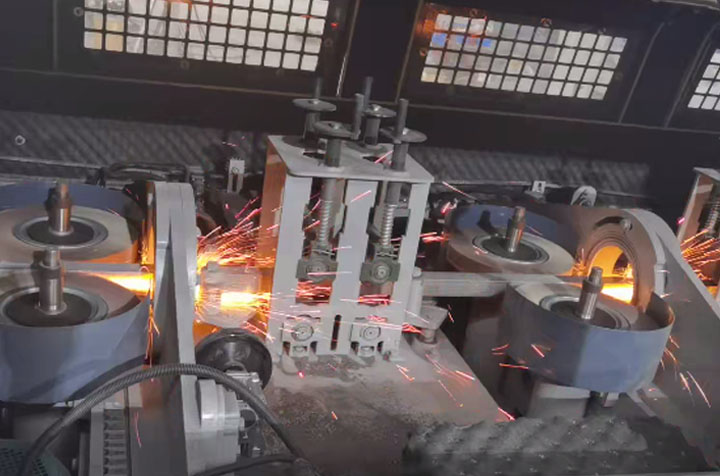

Centerless grinding is a machining process that enables the grinding of cylindrical surfaces without the need for the workpiece to be mounted between centers. This method allows for swift processing of parts, which can significantly reduce production time and costs. The Cincinnati centerless grinder excels in this area, offering superior control and precision. It uses a unique combination of grinding wheels and regulating wheels, which provide stability and enhance the grinding process, resulting in uniformity across large batches.

Key Features of the Cincinnati Centerless Grinder

One of the standout features of the Cincinnati centerless grinder is its user-friendly design. The machine is equipped with various settings that allow operators to easily adjust parameters such as speed, feed rate, and wheel position. This flexibility is crucial in catering to the diverse requirements of different manufacturing processes. Moreover, Cincinnati grinders are known for their durability and reliability, ensuring that they can withstand the rigors of continuous operation while maintaining high performance.

cincinnati centerless grinder supplier

Another significant advantage of the Cincinnati centerless grinder is its ability to accommodate a wide range of workpiece sizes and materials. Whether it’s a small intricate part or a larger, sturdier piece, these grinders can be configured to handle varying dimensions and specifications. This versatility makes them an invaluable tool for manufacturers who require adaptability in their equipment.

The Competitive Edge

In today's competitive manufacturing landscape, efficiency and precision are paramount. By integrating a Cincinnati centerless grinder into their production line, manufacturers can achieve tighter tolerances and better surface finishes, which are critical in applications such as hydraulic components, shafts, and pins. Improvements in product quality not only enhance customer satisfaction but also reduce the likelihood of costly rework or returns.

Furthermore, the reliability of Cincinnati grinders contributes to minimizing downtime, which can disrupt production schedules. These machines are designed for easy maintenance, allowing operators to swiftly perform routine checks and replacements, ultimately ensuring consistent operational uptime.

Conclusion

In summary, the Cincinnati centerless grinder is a cornerstone for manufacturers pursuing excellence in precision grinding. Its innovative design, versatility, and reliability provide businesses with a significant competitive advantage in a fast-paced market. Investing in a Cincinnati centerless grinder means investing in quality, efficiency, and the future success of any manufacturing operation. As industries continue to evolve, tools like the Cincinnati centerless grinder will remain essential in pushing the boundaries of what is possible in precision engineering.