Parts for Cincinnati Centerless Grinders Ensuring Optimal Performance and Longevity

Cincinnati centerless grinders are renowned for their precision and reliability in the machining industry. They offer a unique grinding process that can enhance productivity while maintaining superior tolerances. However, like any precision machinery, they require regular maintenance and replacement parts to ensure optimal performance and prolonged longevity.

Centerless grinding is a method that operates without the need for a fixture to hold the workpiece. Instead, it relies on the grinding wheel and regulating wheel’s unique configuration to maintain the workpiece's position throughout the grinding cycle. This innovative design simplifies the process and increases efficiency, making it the preferred choice for many manufacturers. However, to sustain this efficiency, the quality and condition of the grinder’s components are crucial.

Importance of Quality Replacement Parts

When it comes to maintenance and repairs, using high-quality replacement parts for Cincinnati centerless grinders is indispensable. OEM (Original Equipment Manufacturer) parts are often recommended because they are designed specifically for these machines, ensuring an exact fit and optimal functionality. Using non-OEM parts may save money initially but could lead to performance issues, increased downtime, and ultimately, more significant costs down the road.

Key components that typically require replacement include grinding wheels, regulating wheels, bearings, and spindle assemblies. Each of these parts plays a vital role in the grinding process, and their effective performance significantly affects the overall efficiency of the grinder. For example, worn grinding wheels can lead to poor surface finishes and decreased dimensional accuracy, while faulty bearings could cause increased vibration and wear on the machine.

Maintaining Your Cincinnati Centerless Grinder

Regular maintenance checks are essential for preventing unexpected breakdowns and ensuring that all parts function correctly. Here are some general tips for maintaining Cincinnati centerless grinders

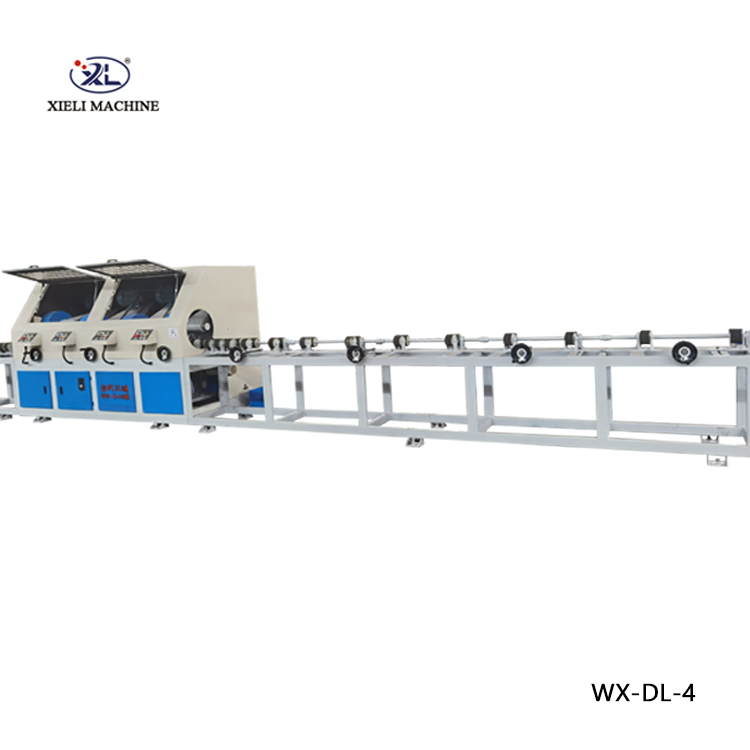

parts for cincinnati centerless grinder products

1. Regular Inspections Frequently examine key components for any signs of wear or damage. This includes checking the grinding wheels for signs of dressing and ensuring that bearings provide smooth operation.

2. Cleaning Keep the machine clean and free from debris. A clean work environment can prevent contaminants from interfering with the grinding process and can prolong the life of machine components.

3. Lubrication Ensure that all moving parts are properly lubricated according to the manufacturer’s specifications. This reduces friction and wear, enhancing the machine’s performance.

4. Alignment Regularly check and adjust the alignment of the grinding and regulating wheels. Proper alignment is crucial to achieving accurate tolerances and maintaining the quality of the finished product.

5. Training Operators Equip operators with the training necessary to recognize signs of wear and to perform basic maintenance. A well-trained operator can identify issues before they escalate into significant problems.

Sourcing Your Parts

When sourcing replacement parts for Cincinnati centerless grinders, it is essential to choose a reputable supplier. Look for companies specializing in industrial machinery and those that stock OEM parts. Reliable suppliers also offer knowledgeable customer service and support, helping you select the right components for your specific model.

In conclusion, maintaining a Cincinnati centerless grinder involves not only performing regular maintenance but also ensuring that high-quality replacement parts are readily available. Investing in quality components and diligent care can significantly enhance the machine’s performance and longevity, ultimately leading to increased productivity and profitability for manufacturing operations. By prioritizing these aspects, manufacturers can expertly navigate the challenges of the machining industry and uphold the precision standards that Cincinnati grinders are known for.