Cincinnati Centerless Grinder Remanufacturing A Premier Solution for Precision Machining

In the world of precision machining, the importance of durable and efficient equipment cannot be overstated. Among the various machines that serve pivotal roles in machining processes, centerless grinders, particularly those manufactured by Cincinnati, hold a distinguished place. The remanufacturing of these high-precision machines not only rejuvenates their performance but also extends their life cycle, offering a cost-effective alternative to new equipment.

Cincinnati centerless grinders are renowned for their ability to produce exceptionally accurate and consistent results. These machines are utilized in a variety of industries, including automotive, aerospace, and medical manufacturing, where precision is paramount. Over time, however, even the most well-maintained grinders may experience wear and tear, leading to diminished performance. Here is where remanufacturing comes into play.

Remanufacturing involves dismantling the entire machine to its core components, inspecting each part for signs of wear, and replacing or repairing anything that does not meet stringent operational standards. This process revitalizes the centerless grinder, restoring it to like-new condition. A reputable supplier specializing in Cincinnati centerless grinder remanufacturing will employ skilled technicians who possess an intimate understanding of the intricacies of these machines. By adhering to original specifications and utilizing high-quality replacement parts, these suppliers ensure that the remanufactured machines can deliver optimal performance.

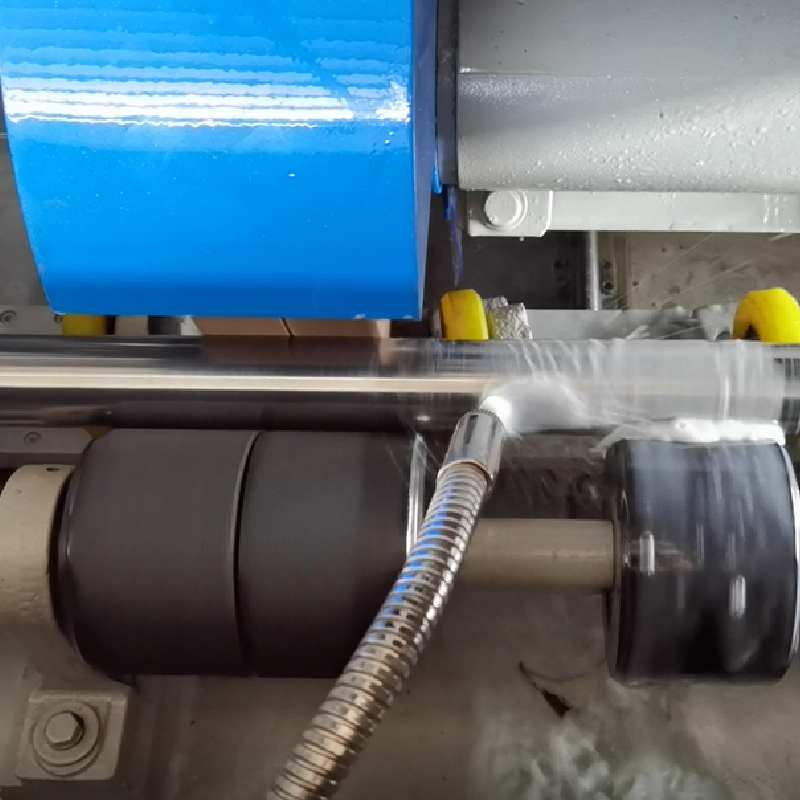

cincinnati centerless grinder remanufacturing supplier

One of the primary benefits of choosing remanufacturing over purchasing new equipment is cost efficiency. New centerless grinders can represent a significant financial investment, often running into hundreds of thousands of dollars. In contrast, remanufactured grinders typically come at a fraction of the cost while still providing reliable performance. Additionally, because remanufacturing allows for the reuse of existing machines, it contributes to sustainability by reducing waste and minimizing resource consumption.

Moreover, many remanufactured Cincinnati centerless grinders come with warranties that rival those of new machines. This assurance not only reflects the confidence suppliers have in their work but also provides peace of mind for manufacturers who depend on these machines for their operations.

In conclusion, Cincinnati centerless grinder remanufacturing is an excellent option for businesses aiming to maintain production efficiency and precision machining capabilities without the substantial investment of buying new equipment. By partnering with experienced suppliers who specialize in remanufacturing, companies can ensure they have access to high-quality machinery that meets their operational requirements. As the manufacturing landscape continues to evolve, remanufactured equipment stands out as a forward-thinking solution that combines performance, sustainability, and cost-effectiveness.