Understanding Cincinnati Centerless Grinder Parts and Their Importance

Cincinnati centerless grinders are renowned in the manufacturing industry for their efficiency and precision in metalworking applications. These machines are specifically designed to grind cylindrical parts without the need for a dedicated fixture or support. The elimination of this requirement not only enhances productivity but also allows for greater flexibility in manufacturing processes. Key to the optimal performance of these grinders are their various parts, each playing a crucial role in the machine's operation.

At the heart of any centerless grinder is the grinding wheel, which is responsible for material removal. Typically made of high-quality abrasive materials, the grinding wheel must be accurately dressed to achieve the desired surface finish. The condition and alignment of the grinding wheel are essential for consistent results; therefore, regular maintenance and timely replacement of this component are critical.

Another essential part of the Cincinnati centerless grinder is the regulating wheel. This wheel controls the rotational speed of the workpiece, allowing precise control over the grinding process. The regulating wheel’s material and surface texture greatly influence the grinding efficiency, and like the grinding wheel, it requires regular inspection and replacement to maintain optimal performance.

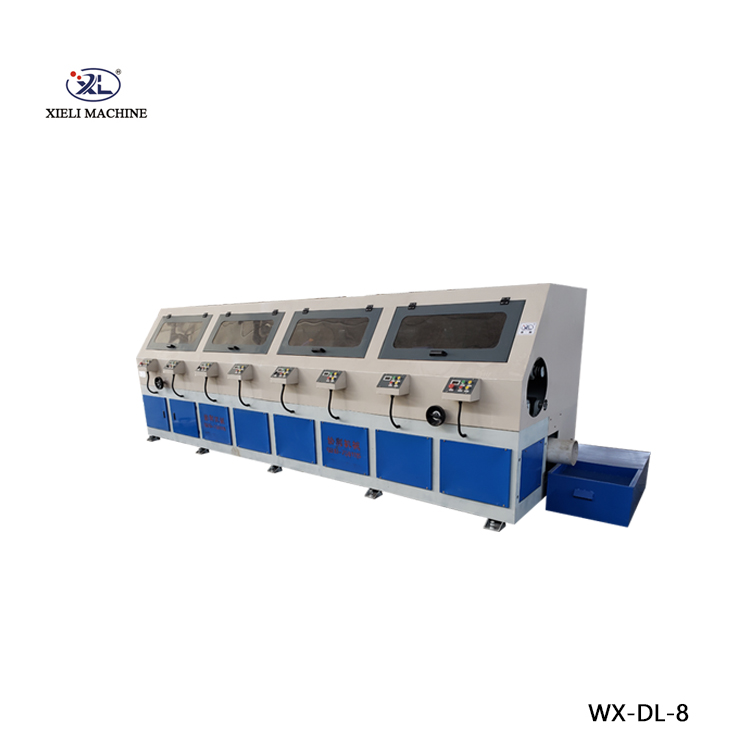

cincinnati centerless grinder parts products

The work rest blade is another important component in the setup of a centerless grinder. Positioned between the grinding wheel and the regulating wheel, the work rest blade supports the workpiece during the grinding operation. Proper adjustment of the work rest blade is crucial, as it ensures that the part remains stable and secure throughout the grinding process, contributing to the overall accuracy of the end product.

In addition to these core components, centerless grinders also contain various accessories and attachments that further enhance their functionality. For instance, infeed attachments can be used for specific part shapes or diameters, while automatic feeding systems can improve efficiency in high-volume production environments.

As with any complex machinery, the longevity and reliability of Cincinnati centerless grinders depend on the quality and condition of their parts. Regular maintenance, including cleaning, lubrication, and timely replacement of worn components, is essential to prevent breakdowns and ensure the machine operates at peak performance. This not only extends the life of the equipment but also reduces operational costs and minimizes downtime.

In conclusion, the parts of Cincinnati centerless grinders are integral to their operation. Understanding the importance of each component helps manufacturers maintain their machines effectively and achieve the high precision required in today’s competitive market. Investing in quality parts and prioritizing regular maintenance can lead to enhanced productivity and superior finished products, ultimately driving success in various machining applications.