Cincinnati Centerless Grinder 325-12 A Vital Tool for Precision Manufacturing

The Cincinnati Centerless Grinder 325-12 is a remarkable piece of engineering that has stood the test of time in the realm of precision manufacturing. Known for its efficiency and reliability, this grinding machine offers unparalleled performance, making it an essential asset for manufacturers looking to achieve high levels of accuracy in their production processes.

Overview of the Cincinnati Centerless Grinder 325-12

The Cincinnati 325-12 is designed to grind cylindrical parts without the need for supporting centers, which makes it a preferred choice for various industrial applications. This machine effectively handles a wide range of workpiece sizes and shapes, providing exceptional versatility. Users can expect tight tolerances and superior finishes, enhancing the overall quality of their products. Ideal for industries such as automotive, aerospace, and tool-making, the 325-12 model plays a crucial role in high-volume production settings.

Features and Benefits

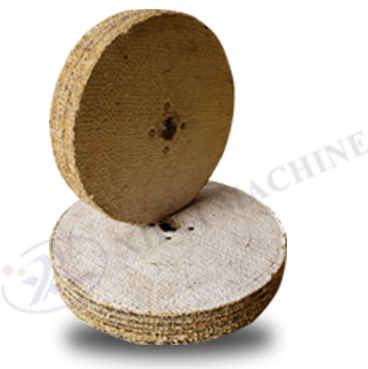

One of the standout features of the Cincinnati 325-12 is its robust construction. Built with high-quality materials, this grinder is designed for durability and long-lasting performance. The precision-engineered components minimize wear and tear, ensuring that the machine operates efficiently over time. Additionally, the machine’s advanced control system allows for easy adjustments, enabling operators to quickly adapt to different grinding requirements.

Another significant benefit of the Cincinnati Centerless Grinder is its ability to process parts at high speed. This high throughput not only increases productivity but also reduces operational costs. Manufacturers can achieve more within a limited timeframe, ultimately leading to greater profitability.

cincinnati centerless grinder 325-12 suppliers

The machine is also equipped with a range of custom options to suit specific manufacturing needs. From varying wheel sizes to adjustable feed rates, the Cincinnati 325-12 can be tailored to meet diverse production demands. This adaptability makes it a worthwhile investment for businesses aiming to stay competitive in today’s fast-paced market.

The Importance of Finding Reliable Suppliers

When it comes to acquiring a Cincinnati Centerless Grinder 325-12, sourcing from reputable suppliers is essential. Quality suppliers not only provide genuine machines but also offer parts and support services that are crucial for maintenance and operational efficiency. It’s advisable to seek suppliers who have a proven track record in the industry, demonstrating their commitment to customer service and technical expertise.

Researching potential suppliers can uncover valuable insights into their reputation and reliability. Reading customer reviews, checking industry certifications, and comparing after-sales services are key steps in selecting the right partner. Attending trade shows and networking within the manufacturing community can also provide recommendations to trustworthy suppliers.

Conclusion

The Cincinnati Centerless Grinder 325-12 stands as a cornerstone in precision manufacturing, embodying efficiency and accuracy. Its robust design, customizable features, and high-speed capabilities make it an invaluable tool for various industries. As businesses strive to meet increasing demands for precision, investing in a reliable grinding machine is crucial.

Sourcing the Cincinnati 325-12 from reputable suppliers ensures that manufacturers receive not only a high-quality grinder but also the necessary support for optimal performance. By prioritizing quality and reliability, companies can enhance their production capabilities, ultimately leading to success in the competitive landscape of precision manufacturing.