The Importance of Round Pipe Polishing Machines in China

In recent years, the demand for high-quality metal products has surged across various industries, including construction, automotive, and manufacturing. A critical factor in achieving this quality is the surface finish of metal components, particularly round pipes. In China, the development and use of advanced round pipe polishing machines have become increasingly essential, transforming the way manufacturers process and deliver their products.

The Importance of Round Pipe Polishing Machines in China

In China, a leading manufacturing hub, the adoption of round pipe polishing machines has contributed significantly to the metalworking industry. Manufacturers are now able to produce pipes with high precision and a superior finish, which are crucial for industries that require stringent quality standards, such as food processing, pharmaceuticals, and aerospace. A polished surface not only improves the visual appeal of metal products but also enhances their resistance to corrosion, thereby extending their lifespan.

china round pipe polishing machine

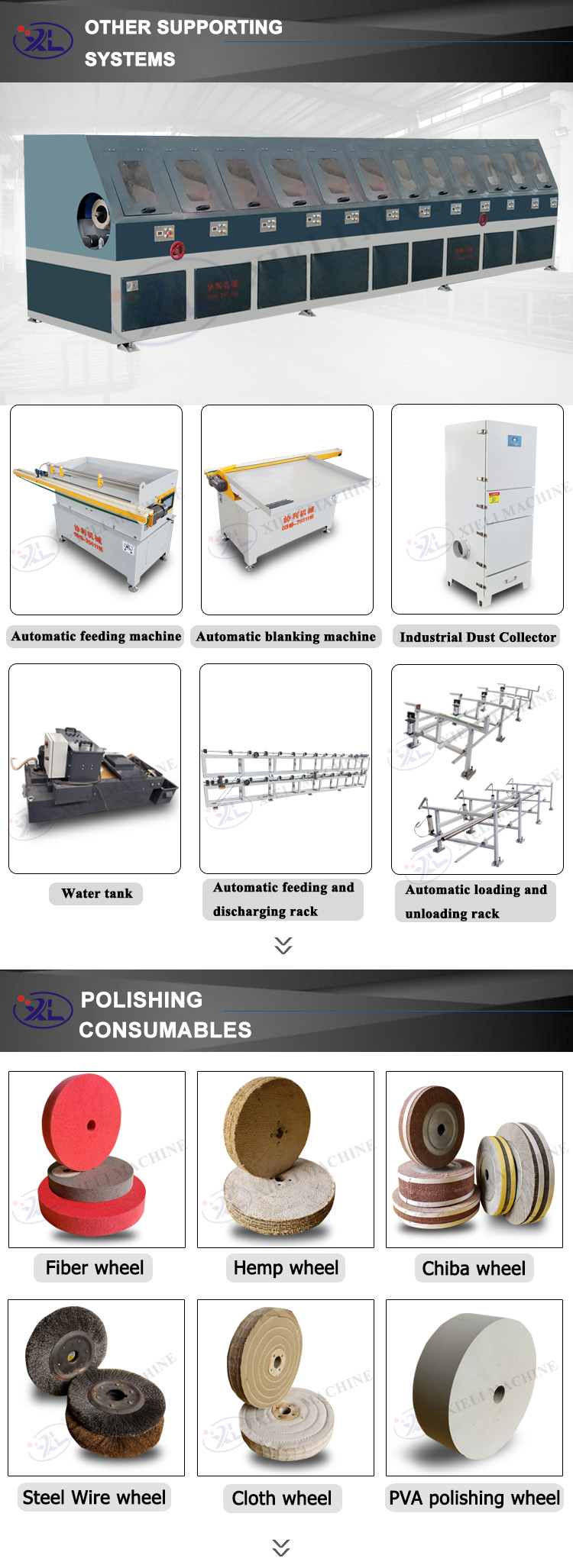

Furthermore, the use of round pipe polishing machines aligns with China's commitment to sustainable manufacturing practices. By investing in efficient polishing technologies, manufacturers can minimize waste and reduce energy consumption during the production process. Modern machines often incorporate features such as dust extraction systems and eco-friendly polishing agents, which contribute to a cleaner working environment and lower environmental impact.

In addition, the growing trend of customization in manufacturing requires round pipes with specific surface finishes. Polishing machines can be adjusted to meet unique customer demands, further allowing manufacturers to differentiate their products in a competitive market. This flexibility is crucial for meeting the diverse needs of clients and ensuring customer satisfaction.

In conclusion, round pipe polishing machines play an integral role in enhancing the quality of metal products in China's manufacturing sector. Their ability to provide superior surface finishes not only meets industry standards but also supports sustainable practices. As technology continues to evolve, it is expected that the efficiency and effectiveness of these machines will further improve, solidifying their importance in the future of manufacturing in China. Investing in advanced polishing solutions will be vital for manufacturers aiming to stay competitive in this rapidly changing landscape.