The Role of China Ovality in Centerless Grinding A Comprehensive Overview

Centerless grinding is a precision machining process that is widely used in the manufacturing industry, particularly for producing cylindrical parts with a high degree of accuracy. This method is characterized by the absence of a spindle, where the workpiece is supported by a rotating wheel and a fixed point of contact, allowing for high-speed, efficient processing of various materials. Central to the success of centerless grinding, particularly in the context of Chinese manufacturing, is the concept of ovality, which refers to the deviation of a cylindrical part from its ideal circular shape.

In many cases, components produced through centerless grinding must meet stringent specifications, especially in sectors such as automotive, aerospace, and medical equipment. Ovality can have severe consequences on the performance and functionality of a given part. As such, understanding the relationship between centerless grinding and ovality is crucial for manufacturers looking to maintain quality and precision.

The Importance of Precision

Ovality affects how parts fit together and function within a larger assembly

. For instance, in the automotive industry, shafts that are even slightly out of round can lead to issues such as increased wear, vibration, and ultimately, premature failure of components. Therefore, manufacturers strive to minimize ovality in their products, which is where the intricacies of centerless grinding come into play.In Chinese manufacturing, where cost competitiveness is paramount, achieving high precision in centerless grinding processes is a critical factor. Companies have invested in advanced technologies, such as CNC centerless grinders, that offer enhanced control over the grinding process. These machines utilize sensors and software algorithms to monitor and adjust key parameters, thereby reducing the risk of producing oval components.

Factors Influencing Ovality in Centerless Grinding

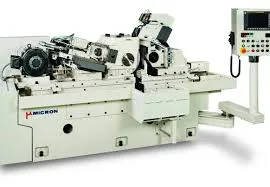

china ovality in centerless grinder

Several factors contribute to the occurrence of ovality during the centerless grinding process. One crucial element is the alignment and setup of the grinding machine. Any misalignment can lead to uneven pressure on the workpiece, resulting in an out-of-round condition. Moreover, the choice of grinding wheel material and the specific grinding parameters (such as feed rate, wheel speed, and coolant application) can greatly influence the outcome.

Additionally, the geometry of the workpiece itself plays a significant role in determining ovality. Variations in diameter, length, and surface roughness can all affect the grinding process and the final shape of the part. In the context of Chinese manufacturing, companies are increasingly implementing stringent quality control measures to ensure that these variables are accounted for, minimizing the risk of ovality.

Technological Advancements and Innovations

The Chinese manufacturing sector has been undergoing rapid transformation, fueled by advancements in technology and automation. Modern centerless grinding machines are now equipped with state-of-the-art features such as real-time monitoring systems and adaptive feedback controls. These technologies allow for dynamic adjustments during the grinding process, thereby reducing ovality and improving overall part quality.

Additionally, manufacturers in China are leveraging data analytics to optimize their grinding processes. By analyzing historical machining data, operators can identify patterns and correlations that contribute to ovality. This data-driven approach enables manufacturers to fine-tune their processes and enhance their capabilities.

Conclusion

In conclusion, ovality is a critical consideration in the realm of centerless grinding, especially for manufacturers in China striving for high precision and quality. Through careful attention to machine setup, grinding parameters, and technological innovations, it is possible to minimize ovality and produce components that meet stringent industry standards. As the manufacturing landscape continues to evolve, the integration of advanced technologies will play a pivotal role in enhancing the capabilities of centerless grinding processes, ultimately driving improvements in product quality and operational efficiency. By addressing the challenges posed by ovality, manufacturers can ensure their competitiveness in a global market and deliver superior products that meet the demands of modern industries.