Understanding China’s Junker Centerless Grinder A Technical Overview

In the realm of manufacturing and precision engineering, the role of grinding machines cannot be overstated. Among them, the centerless grinder stands out as a vital tool for achieving high precision and efficiency in workpieces. China, with its robust industrial framework, has made significant strides in the development and production of advanced machinery, including the Junker centerless grinder. This article explores the features, advantages, and applications of the Junker centerless grinder in China.

What is a Centerless Grinder?

A centerless grinder is a type of grinding machine that differs from traditional cylindrical grinders in its operational approach. Rather than supporting the workpiece between centers, a centerless grinder uses a combination of wheels to support and grind the workpiece from the outside. This method allows for continuous production of cylindrical parts without the extensive setup times associated with center-based grinding.

The Junker Centerless Grinder

The Junker brand is synonymous with quality in the world of grinding technology. With a heritage of innovation and commitment to precision, the Junker centerless grinder produced in China embodies these principles. The machine is designed to grind workpieces in a highly efficient manner, providing exceptional quality finishes and tight tolerances.

One of the key features of the Junker centerless grinder is its advanced control systems that allow for automated operations. This automation not only enhances productivity but also minimizes the likelihood of human error, resulting in consistent output quality. Additionally, the machine is equipped with high-speed spindles, which enable faster grinding processes and improved machine utilization.

Advantages of the Junker Centerless Grinder

1. High Precision and Quality The Junker centerless grinder is engineered to achieve tight tolerances, making it an ideal choice for industries that require high precision, such as aerospace, automotive, and medical equipment manufacturing.

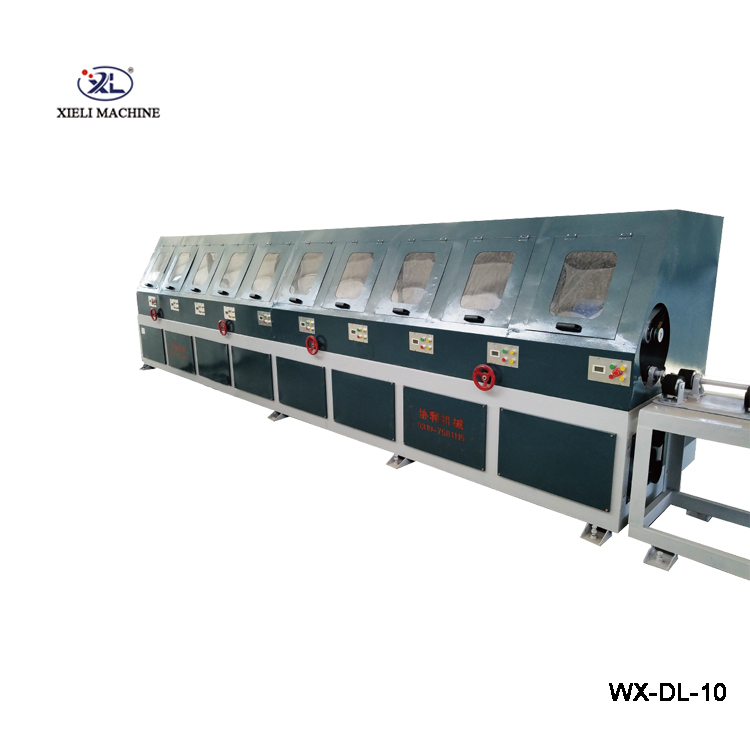

china junker centerless grinder

2. Increased Production Efficiency The design of the centerless grinder allows for the continuous feeding of workpieces, significantly increasing throughput. Manufacturers can produce a large number of components in a shorter timeframe compared to traditional grinding methods.

3. Versatile Applications The versatility of the Junker centerless grinder enables it to handle various materials, including steel, aluminum, and even exotic materials. This adaptability makes it suitable for a wide range of industrial applications.

4. Reduced Setup Time The centerless design minimizes the complexity of setup processes. This allows manufacturers to switch between different workpieces quickly, facilitating efficient production line changes.

5. Cost-Effectiveness While the initial investment in a high-quality Junker centerless grinder may be significant, the long-term savings in labor costs, production time, and waste reduction make it a cost-effective option for manufacturers.

Applications in Industry

The applications of the Junker centerless grinder are extensive. In the automotive sector, it is used to grind components such as shafts, bearings, and gears, which require precise dimensions and surface finishes. Similarly, in the aerospace industry, it plays a critical role in manufacturing parts that must meet stringent safety and performance standards.

The medical device industry also leverages the capabilities of the Junker centerless grinder to produce components like surgical instruments and implants, where precision and quality are paramount. Beyond these sectors, the versatility of the machine allows it to find use in various manufacturing processes across multiple industries.

Conclusion

The Junker centerless grinder represents a significant advancement in grinding technology, providing manufacturers in China and globally with the tools necessary to enhance productivity, precision, and overall operational efficiency. As industries continue to evolve and demand higher standards, the role of high-quality machinery like the Junker centerless grinder will remain critical in meeting these challenges. With its innovative features and versatility, it stands as a testament to the progress made in the manufacturing sector, ensuring that businesses can remain competitive in an ever-changing marketplace.