The Evolution and Importance of Buffing Polishing Machines in China

In the manufacturing landscape of China, buffing and polishing machines play an essential role in enhancing the finish and quality of various products. As industries evolve, the significance of these machines, particularly in sectors like automotive, aerospace, electronics, and furniture manufacturing, has grown tremendously. This article explores the development, applications, and future prospects of buffing polishing machines in China.

Understanding Buffing Polishing Machines

Buffing polishing machines are specialized equipment designed to smooth and shine surfaces through abrasive action. They are widely used to achieve a fine finish on materials such as metals, plastics, and wood. The processes involved generally include buffing, which involves the use of soft, fluffy wheels with fine polishing compounds to remove any surface imperfections, and polishing, which uses harder wheels or pads alongside abrasives to refine the surface finish.

Historical Context and Development in China

China's journey in the manufacturing sector has witnessed remarkable transformations over the past few decades. Initially focused on meeting local demands, the industry has expanded significantly, now competing on a global scale. The introduction of advanced buffing and polishing technologies has been central to this growth. Early machines were rudimentary, often operated manually, and lacked precision. However, advancements in automation and robotics have revolutionized how these machines operate, enhancing efficiency, consistency, and quality.

Today, Chinese manufacturers produce a wide range of buffing polishing machines, from small bench-top models to large industrial systems capable of processing massive volumes. The integration of computer numerical control (CNC) technology allows for more precise operations, ensuring that products meet the stringent specifications required in modern manufacturing.

Applications of Buffing Polishing Machines

The versatility of buffing and polishing machines has led to their incorporation across various industries

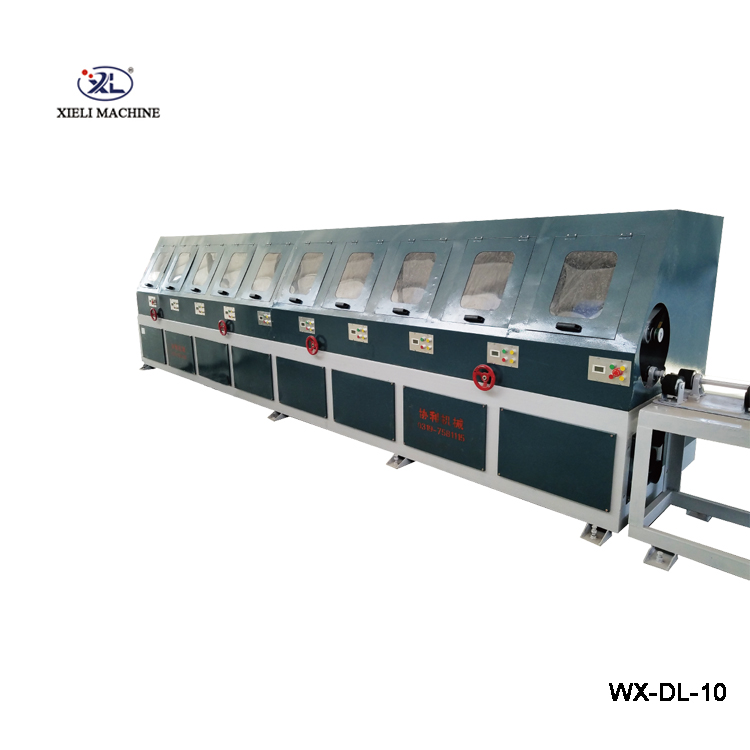

china buffing polishing machine

1. Automotive Sector In automotive manufacturing, these machines are critical for achieving the high gloss finishes demanded by consumers. Components such as wheels, grilles, and trim pieces often require buffing and polishing to enhance their aesthetic appeal and protect against corrosion.

2. Aerospace Industry The aerospace sector demands the highest levels of precision and safety. Buffing and polishing machines are essential for maintaining the integrity of aircraft components, ensuring that surfaces are smooth and free from defects that could compromise performance.

3. Electronics Manufacturing In electronics, the finishing of components is vital for both function and appearance. Buffing and polishing machines help eliminate surface flaws that can affect the performance of devices, ensuring a reliable and visually appealing product.

4. Furniture Production The furniture industry benefits from buffing and polishing machines to achieve smooth and shiny wood finishes, enhancing both the look and feel of the product while also providing protection against wear.

Future Prospects

Looking forward, the demand for sophisticated buffing polishing machines in China is expected to continue growing. As industries increasingly emphasize sustainability and efficiency, manufacturers are investing in advanced technologies. Automating the buffing and polishing processes reduces labor costs and enhances product consistency. Moreover, the development of eco-friendly polishing compounds is gaining traction, aligning with global sustainability trends.

In addition, with the rise of smart manufacturing and Industry 4.0, buffing and polishing machines are becoming integral to interconnected production systems. Real-time monitoring and data analytics can now optimize the performance of these machines, ensuring minimal waste and maximal efficiency.

Conclusion

In summary, buffing polishing machines are indispensable to the manufacturing landscape in China, contributing significantly to various industries' quality and efficiency. As technology continues to innovate, these machines will evolve, shaping the future of manufacturing not only in China but across the globe. The continued investment in advanced buffing and polishing technologies signifies a commitment to excellence, sustainability, and adaptability in an ever-competitive market.