Revolutionizing Metal Finishing with China’s Automatic Metal Polishing Machines

In recent years, the manufacturing sector has witnessed significant advancements, especially in the field of metal processing. Among these innovations, China’s automatic metal polishing machines stand out, combining efficiency, precision, and ease of use. These machines are vital for industries ranging from automotive to aerospace, where surface finish quality can significantly impact product performance and aesthetics.

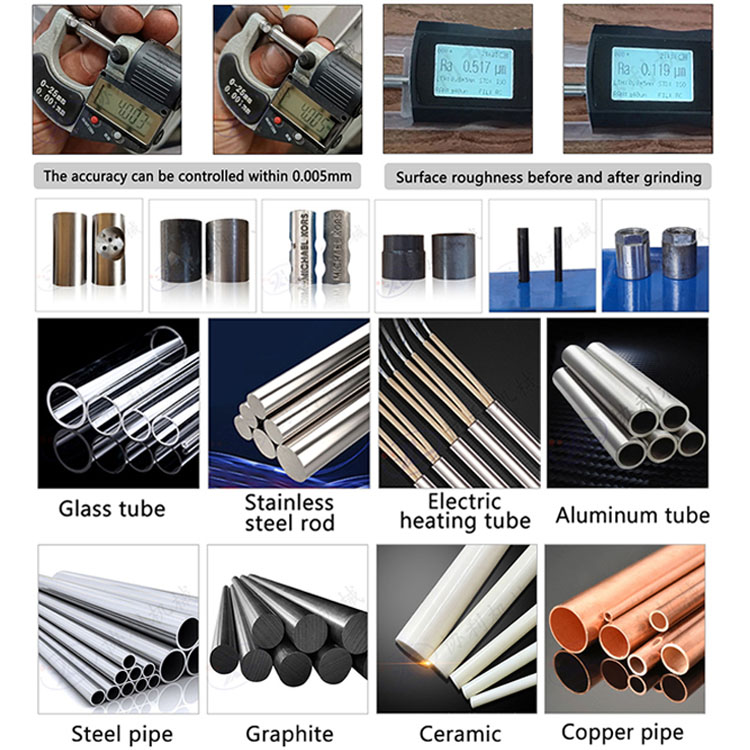

Automatic metal polishing machines are designed to enhance the surface finish of various metals, including stainless steel, aluminum, and brass. The need for these machines arises from the increasing demands for higher quality and precision in metal components. Manual polishing processes are often time-consuming and require skilled labor, which can lead to inconsistencies in the finish. In contrast, automatic polishing machines ensure uniformity and reduce labor costs while improving production speeds.

China has become a leader in manufacturing these advanced machines, providing a wide array of options to meet the needs of different industries. The technology behind these machines incorporates state-of-the-art features such as programmable controls, automated feeding systems, and high-precision polishing heads. These innovations allow for the adjustment of polishing parameters such as speed, pressure, and duration, enabling manufacturers to achieve specific surface finishes tailored to their requirements.

One of the key advantages of automatic metal polishing machines is their ability to handle large volumes of components efficiently. In industries such as automotive manufacturing, where thousands of parts may require polishing, automation significantly increases productivity. This efficiency not only cuts down on production time but also ensures that the final products meet the rigorous quality standards necessary in competitive markets.

china automatic metal polishing machine

Moreover, environmental considerations have prompted the development of more sustainable polishing solutions. Modern automatic polishing machines are equipped with features that minimize waste and reduce the environmental impact of the polishing process. For example, they often utilize closed-loop water systems and efficient dust collection mechanisms to curb pollution and promote recycling of materials.

The versatility of automatic metal polishing machines also cannot be understated. They can be used for various polishing techniques, including buffing, surface grinding, and electro-polishing. This adaptability makes them suitable for a wide range of applications, from creating the high-gloss finish desired in consumer products to preparing components for further processing in aerospace and medical equipment.

As industries continue to evolve, the role of automation becomes increasingly critical. In China, the ongoing investment in research and development is driving innovation in automatic metal polishing technologies. Manufacturers are continuously working to improve machine capabilities, focusing on enhancing user interfaces, integrating IoT for better monitoring and control, and developing more compact designs that can fit into smaller manufacturing environments.

In conclusion, China’s automatic metal polishing machines represent a significant leap forward in manufacturing technology. Their ability to provide consistent, high-quality finishes while increasing efficiency and reducing environmental impact makes them invaluable across various sectors. As technology continues to advance, these machines will undoubtedly play a critical role in shaping the future of metal processing and manufacturing, ensuring that quality and sustainability go hand in hand.