Exploring Affordable SMT Centerless Grinders A Comprehensive Guide

In the realm of precision machining, the importance of a centerless grinder cannot be overstated. These machines are fundamental in manufacturing processes that require the shaping and finishing of cylindrical parts. Among the various types available on the market, the SMT centerless grinder stands out for its cost-effectiveness and efficiency. This article delves into the features, benefits, and considerations of choosing an affordable SMT centerless grinder for your machining needs.

What is a Centerless Grinder?

A centerless grinder is a type of grinding machine that grinds cylindrical parts without the need for prior mounting. Unlike traditional grinders, which require the workpiece to be centered between two points, a centerless grinder allows the workpiece to be held in place by two rotating wheels. This unique setup facilitates continuous and uninterrupted grinding, leading to high production rates and consistent quality.

Advantages of SMT Centerless Grinders

SMT (Surface Mount Technology) centerless grinders are particularly appealing due to their affordability and specialized features. They are designed to deliver precise and efficient results, making them suitable for various applications, including automotive parts, medical devices, and aerospace components.

1. Cost-Effective Solutions One of the most significant advantages of SMT centerless grinders is their affordability. Unlike high-end models that may cost a fortune, SMT grinders provide a viable option for small to medium-sized businesses, helping them maintain competitive pricing without sacrificing quality.

2. High Precision SMT grinders are engineered to achieve tight tolerances and smooth finishes. They can grind parts to an exceptional degree of accuracy, which is essential for industries where precision is paramount.

3. User-Friendly Operation Many SMT centerless grinders come equipped with intuitive controls and automatic features, making them easy to operate even for those with limited experience. This usability helps reduce training time and increases overall productivity.

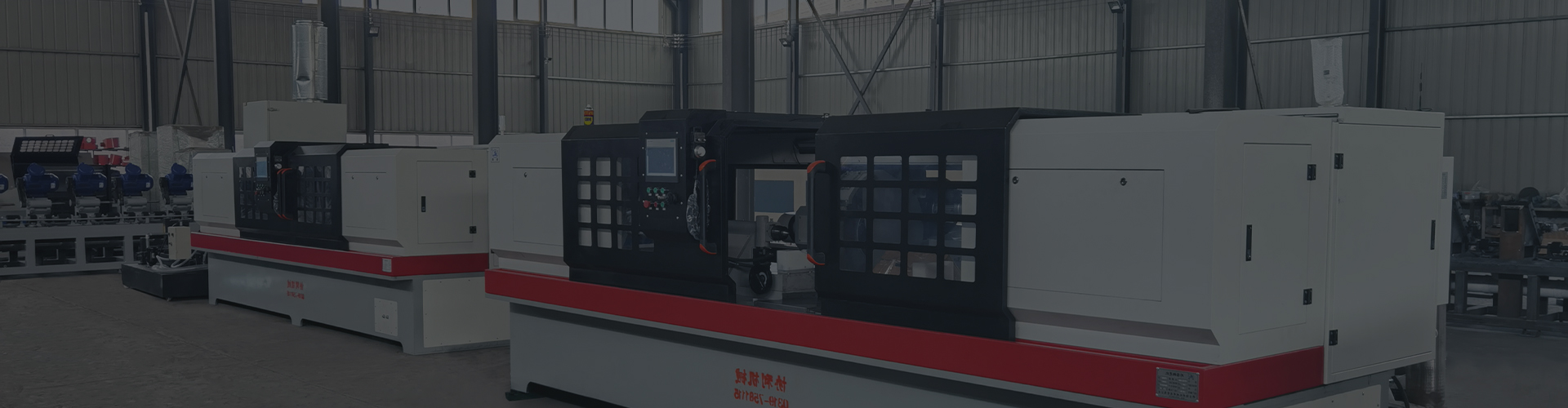

cheap smt centerless grinder

4. Versatility These grinders can handle a variety of materials, including steel, aluminum, and plastic. This versatility makes them suitable for various projects, enhancing their utility in different manufacturing environments.

Considerations When Choosing an SMT Centerless Grinder

While the benefits of SMT centerless grinders are compelling, potential buyers should consider several factors before making a purchase.

- Size and Footprint Assess the available floor space in your workshop. SMT grinders come in different sizes, so it’s crucial to choose one that fits your operational workflow without occupying excessive space.

- Production Volume Determine the volume of work you plan to process. Some SMT grinders are better suited for higher production volumes, while others excel in lower-volume applications.

- Maintenance Requirements Understand the maintenance needs of the machine. Affordable models might require more frequent servicing, which can affect long-term costs.

- Technical Support and Warranty Research the manufacturer’s reputation for customer support. A good warranty and accessible technical support can save you time and money in case of any issues.

Conclusion

In summary, affordable SMT centerless grinders offer an excellent solution for businesses looking to enhance their machining capabilities while maintaining a budget. With their high precision, user-friendly operation, and versatility, these machines represent a valuable investment for companies across various industries. By carefully considering your specific needs and available options, you can find the right SMT centerless grinder that aligns with your operational goals.