The Affordable Shumag Centerless Grinder A Game Changer for Precision Machining

In the world of precision machining, efficiency and accuracy are paramount. Among the various tools utilized in manufacturing processes, centerless grinders stand out for their ability to achieve tight tolerances and high production rates. For many businesses, particularly small and medium-sized enterprises, the cost of purchasing such specialized machinery can be a significant barrier. Enter the affordable Shumag centerless grinder, a revolutionary solution that combines quality, performance, and cost-effectiveness.

Understanding Centerless Grinding

Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece. Unlike traditional grinding methods where the workpiece is held in place between two centers, in centerless grinding, the workpiece is supported by a work rest blade and is fed between a grinding wheel and a regulating wheel. This setup allows for continuous production, making it ideal for processing cylindrical components.

The key advantages of centerless grinding include its ability to grind parts without the need for complex setups, high rates of material removal, and the capacity to grind multiple parts simultaneously. These features make it particularly popular in industries such as automotive, aerospace, and manufacturing of precision components.

The Shumag Centerless Grinder Features and Benefits

The Shumag centerless grinder is designed with affordability in mind, making it accessible to businesses that previously might have shied away from investing in such equipment. Here are some of the notable features and benefits it offers

1. Cost-Effectiveness One of the standout aspects of the Shumag centerless grinder is its competitive pricing. By reducing overhead costs and streamlining manufacturing processes, it allows companies to achieve a return on investment without the financial strain typically associated with high-end machinery.

2. User-Friendly Design The Shumag centerless grinder boasts an intuitive interface and straightforward setup, enabling operators to quickly learn how to use the machine effectively. This reduces the learning curve and minimizes downtime during training.

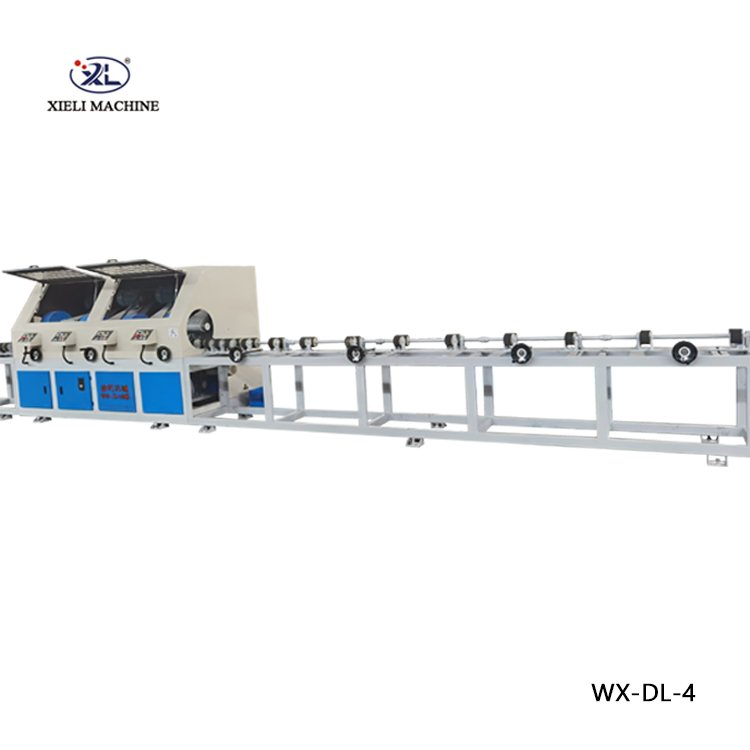

cheap schumag centerless grinder

3. Compact Size Many traditional centerless grinders can occupy a significant amount of floor space. The Shumag model is designed to be compact, allowing it to fit comfortably into smaller workshops while maintaining the capacity for higher production volumes.

4. Versatility This grinder can handle various materials and sizes, making it suitable for a wide range of applications. Whether working with hard metals or softer materials, the Shumag centerless grinder adapts to meet the demands of different projects.

5. Precision Engineering Despite being affordable, the Shumag centerless grinder does not compromise on precision. It features advanced engineering that ensures consistent accuracy, allowing businesses to produce high-quality components that meet stringent specifications.

Transforming Machining Operations

The introduction of the Shumag centerless grinder has the potential to transform machining operations in various industrial sectors. Businesses can achieve higher production rates without sacrificing quality, allowing them to compete more effectively in the marketplace. Smaller companies, in particular, can leverage this technology to expand their capabilities without overwhelming their budgets.

Moreover, as companies increasingly focus on automation and efficiency, the Shumag grinder can easily integrate into existing manufacturing setups. Its adaptability makes it possible for businesses to innovate and optimize processes continually.

Conclusion

In a competitive industry where precision and efficiency are critical, investing in the right machinery can make all the difference. The affordable Shumag centerless grinder offers a compelling solution for businesses looking to enhance their grinding capabilities without incurring substantial costs. With its user-friendly design, versatility, and impressive engineering, this machine is poised to become a staple in workshops looking to strike the perfect balance between quality and affordability. By embracing such advancements, companies can position themselves for success in an ever-evolving manufacturing landscape.