The Rise of Cheap Internal Centerless Grinding Machines

In the world of precision machining, the necessity for reliable and efficient machinery is paramount. One machine that has captured the attention of manufacturers looking for cost-effective solutions is the internal centerless grinding machine. As industries continually seek ways to reduce costs while maintaining high quality, the emergence of affordable internal centerless grinding machines has revolutionized the manufacturing landscape.

Understanding Internal Centerless Grinding

Internal centerless grinding is a technique used to finish machine the inner diameters of various components. Unlike traditional grinding methods, centerless grinding does not require a fixed center. Instead, the workpiece is placed between a grinding wheel and a regulating wheel, allowing for continuous workpiece rotation and movement. This method is particularly advantageous for cylindrical components and offers exceptional precision, which is critical in fields such as automotive, aerospace, and medical device manufacturing.

The benefits of centerless grinding extend beyond precision. The process is highly efficient, allowing for the mass production of components with minimal setup time. However, the initial investment in high-quality grinding machines can often be a hurdle for small to medium-sized enterprises. Enter the affordable internal centerless grinding machines, which are engineered to meet the demands of cost-conscious businesses while delivering reliable performance.

The Advantages of Affordable Machines

The market for cheap internal centerless grinding machines has been bolstered by advancements in technology and increased competition among manufacturers. By utilizing more efficient production techniques and streamlining operations, companies can now offer high-quality machinery at lower prices. This accessibility empowers even small manufacturers to incorporate centerless grinding into their production processes.

The benefits of these affordable machines are manifold

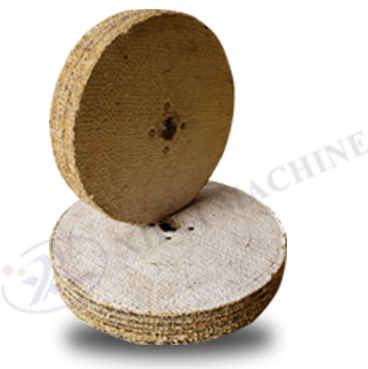

cheap internal centerless grinding machine

2. Increased Productivity The efficiency of centerless grinding allows for higher throughput, resulting in increased production rates and reduced lead times.

3. Versatility Cheap internal centerless grinding machines can handle a wide variety of materials and component sizes, making them suitable for diverse applications.

4. User-Friendly Many of these machines are designed with simplified controls, making them accessible even for operators with minimal experience.

5. Space Efficiency Internal centerless grinding machines are typically more compact than other options, allowing businesses with limited floor space to incorporate them without extensive redesign.

The Future of Centerless Grinding Technology

As technology continues to advance, the capabilities of cheap internal centerless grinding machines are expected to improve further. Innovations in automation, digitization, and artificial intelligence are already influencing the machining landscape, and these trends will likely enhance the performance and efficiency of affordable machinery.

Moreover, as industries place increased emphasis on sustainability, manufacturers are also focusing on producing machines that minimize waste and energy consumption.

Conclusion

The emergence of affordable internal centerless grinding machines has opened doors for manufacturers of all sizes. By embracing these cost-effective solutions, companies can enhance their production capabilities without compromising quality. As technology progresses, the potential for further advancements in this field is immense, ensuring that precision machining remains at the forefront of manufacturing innovation. For businesses ready to take the plunge, investing in cheap internal centerless grinding machines may be the key to unlocking greater efficiency and productivity in an increasingly competitive market.