Affordable Infeed Centerless Grinders A Game Changer for Precision Machining

In the world of precision machining, grinding plays a crucial role in achieving the desired surface finish and dimensional accuracy of components. Centerless grinding, in particular, offers a unique approach that enhances productivity and efficiency. For businesses looking to maintain competitiveness while managing costs, the emergence of affordable infeed centerless grinders presents an exciting opportunity.

Affordable Infeed Centerless Grinders A Game Changer for Precision Machining

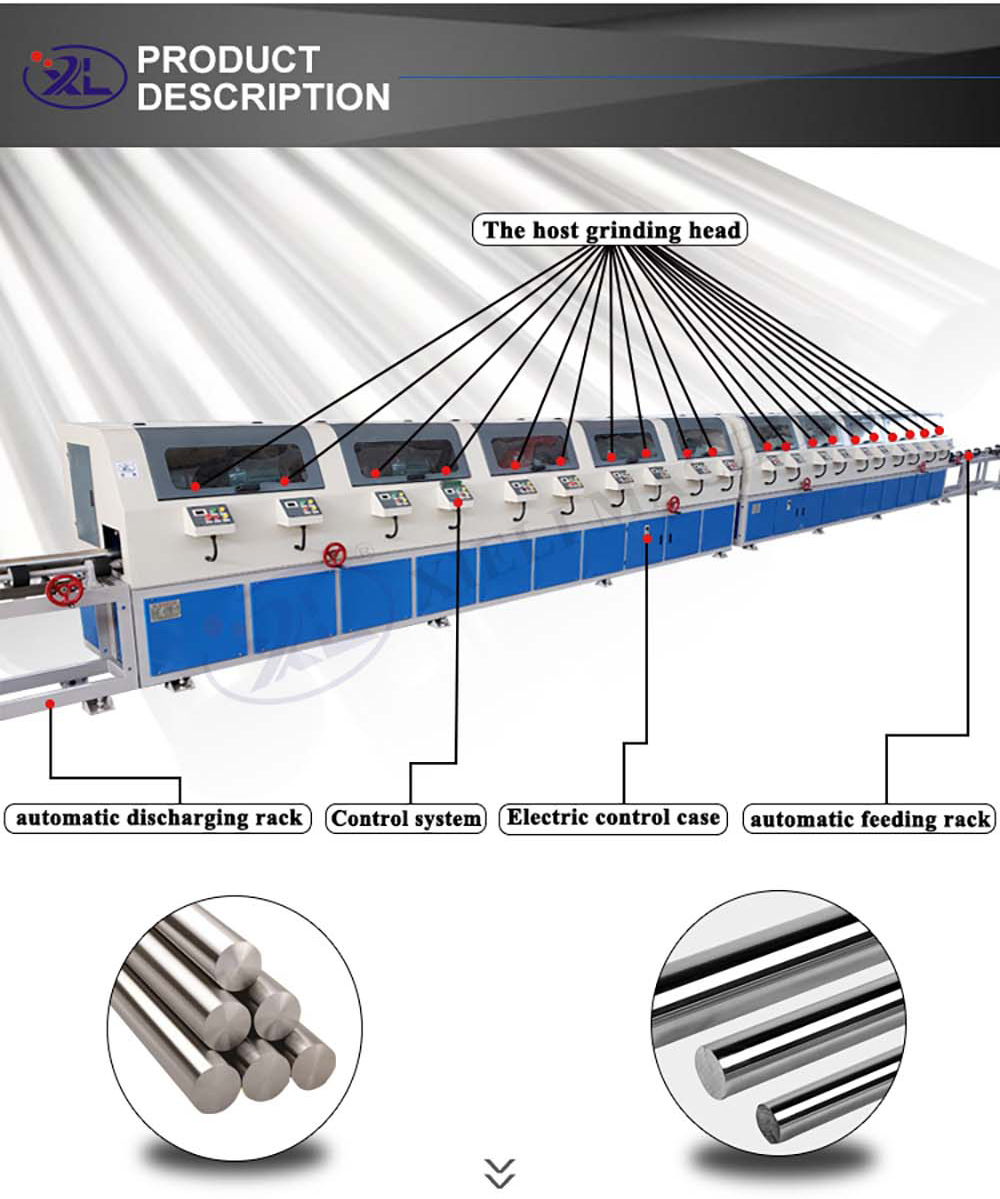

One of the key advantages of these affordable machines is their ability to maintain precision in grinding operations while minimizing operator intervention. With features such as automatic feeding systems and digital controls, users can expect consistent results, significantly reducing the likelihood of human error. This boost in reliability not only enhances product quality but also increases throughput, allowing businesses to meet tight deadlines without sacrificing standards.

cheap infeed centerless grinder

Furthermore, modern infeed centerless grinders incorporate innovative designs that focus on user-friendliness and maintenance. Many of these machines feature compact designs suitable for workshop environments with limited space. This is particularly beneficial for smaller operations that need to optimize their workspace utilization. Additionally, ease of maintenance ensures that these grinders can remain in operation with minimal downtime, further enhancing productivity.

Another significant aspect of affordable infeed centerless grinders is their versatility. These machines can handle a wide variety of materials, from soft metals to hardened steel, accommodating different applications and industry needs. This flexibility is essential for manufacturers who may deal with diverse product lines but want to keep their equipment investment lean.

In conclusion, the introduction of affordable infeed centerless grinders marks a pivotal turning point for companies aiming to enhance their machining capabilities without overstretching their budgets. By investing in these advanced yet economical grinding solutions, businesses can improve their operational efficiency, ensure high-quality output, and remain competitive in an ever-evolving market. As the industry continues to embrace technological advancements, the future looks bright for precision machining enthusiasts ready to take their operations to the next level.