Affordable Cincinnati Centerless Grinding Machines A Comprehensive Overview

When it comes to precision machining, centerless grinding is a crucial process employed in various industries, including automotive, aerospace, and manufacturing. Among the pioneers in this field, Cincinnati molienda sin centro (Cincinnati Centerless Grinding Machines) has gained a reputation for delivering high-quality machines that ensure optimal performance and reliability. Today, we will explore the benefits of investing in affordable Cincinnati centerless grinding machines, including their features, advantages, and the impact they have on productivity and cost-efficiency.

What is Centerless Grinding?

Centerless grinding is a machining process that uses abrasive cutting to remove material from the surface of a workpiece. Unlike traditional grinding, which requires the workpiece to be clamped between centers, centerless grinding holds the workpiece using a combination of a regulating wheel and a grinding wheel. This setup allows for continuous and consistent grinding without the need for complex setups, making it a popular choice among manufacturers.

The Cincinnati Advantage

Cincinnati is well-known for producing reliable and efficient centerless grinding machines. Their equipment is designed to cater to a variety of industries and applications, ensuring that users receive high-quality performance tailored to their needs. One of the key advantages of Cincinnati centerless grinding machines is their advanced technology, which allows for precise and repeatable grinding processes. This is crucial in industries where tolerances are tight, and even the slightest deviation can lead to significant quality issues.

Cost-Effectiveness of Cincinnati Centerless Grinding Machines

While high-quality machinery often comes with a steep price tag, Cincinnati has made significant strides to offer affordable options without compromising on quality. Their machines come equipped with features that maximize productivity while minimizing operational costs. For instance, Cincinnati centerless grinding machines boast energy-efficient designs and advanced automation capabilities, which reduce manual labor and downtime. This results in lower overall production costs, making them a cost-effective option for companies seeking to enhance their machining processes.

Features of Affordable Cincinnati Centerless Grinding Machines

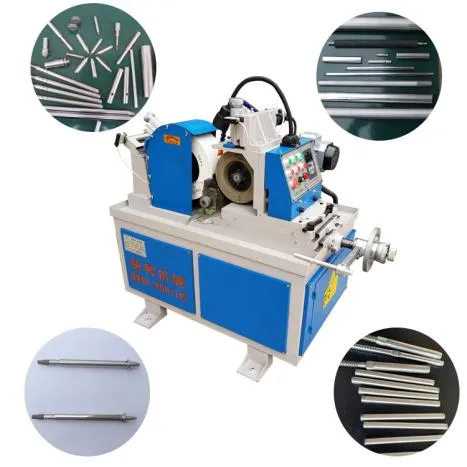

cheap cincinnati centerless grinding machine

Cincinnati's centerless grinding machines are packed with features that make them appealing to businesses looking for efficiency and performance

1. User-Friendly Controls Many models come with intuitive control systems that allow operators to easily set up and adjust grinding parameters, reducing the learning curve and increasing overall productivity.

2. Durability and Reliability Made from high-quality materials and components, Cincinnati machines are built to withstand rigorous use, ensuring longevity and reduced maintenance costs.

3. Versatility Cincinnati centerless grinding machines support a wide range of workpieces, including various sizes and materials. This versatility makes them suitable for multiple applications, reducing the need for multiple machines.

4. Speed and Precision The design of Cincinnati machines facilitates high-speed grinding processes without sacrificing accuracy, which is critical for achieving tight tolerances.

The Impact on Productivity

Investing in affordable Cincinnati centerless grinding machines can have a profound impact on a company's productivity. By streamlining the grinding process, businesses can reduce cycle times and enhance throughput. In addition, the consistency offered by these machines leads to lower scrap rates and improved product quality, which ultimately translates to higher customer satisfaction.

Conclusion

In summary, affordable Cincinnati centerless grinding machines represent a wise investment for businesses looking to enhance their machining capabilities. Their advanced features, cost-efficiency, and reliability make them an ideal choice for companies across various sectors. By integrating these machines into their operations, manufacturers can improve their productivity, reduce costs, and maintain a competitive edge in a fast-evolving market. For those exploring options in precision machining, Cincinnati's offerings warrant serious consideration as a pathway to achieving operational excellence.