The Advantages of Cheap Centerless Tube Polishing Machines

In today’s competitive manufacturing landscape, efficiency and quality stand at the forefront of production processes. One essential aspect of manufacturing, particularly for metal products, is the finishing process. Among various finishing techniques, tube polishing plays a vital role in enhancing the aesthetics and functional performance of metallic tubes. This is where centerless tube polishing machines come into play, especially those that are affordably priced.

What is a Centerless Tube Polishing Machine?

A centerless tube polishing machine is a specialized device designed to smooth and polish cylindrical workpieces. Unlike conventional polishing methods, which often require a spindle for centering, centerless polishing utilizes a different approach. This type of machine allows for the continuous feeding of tubes without the need for specific fixtures or centers. The tube is placed between two rotating wheels, one wheel is fixed while the other is adjustable, allowing for precise control over the polishing process.

Cost-Effectiveness of Cheap Centerless Tube Polishing Machines

One of the key advantages of cheap centerless tube polishing machines is their affordability. Manufacturers often find themselves compelled to reduce costs without compromising on quality. A low-cost polishing machine can deliver impressive results without draining resources. These machines can cater to small to medium-sized companies that might not have the budget for high-end, complex polishing systems. Investing in these cost-effective machines enables businesses to maintain production outputs while optimizing their operational budgets.

Efficiency and Productivity

Centerless tube polishing machines are designed for high-speed operations. Their bulk processing capabilities enable companies to handle a large volume of work in significantly less time compared to manual polishing. This efficiency translates into increased productivity, and when operations run more swiftly, the overall throughput of manufacturing improves. By integrating cheap centerless tube polishing machines, companies can achieve higher output rates without the usual labor-intensive processes associated with tube polishing.

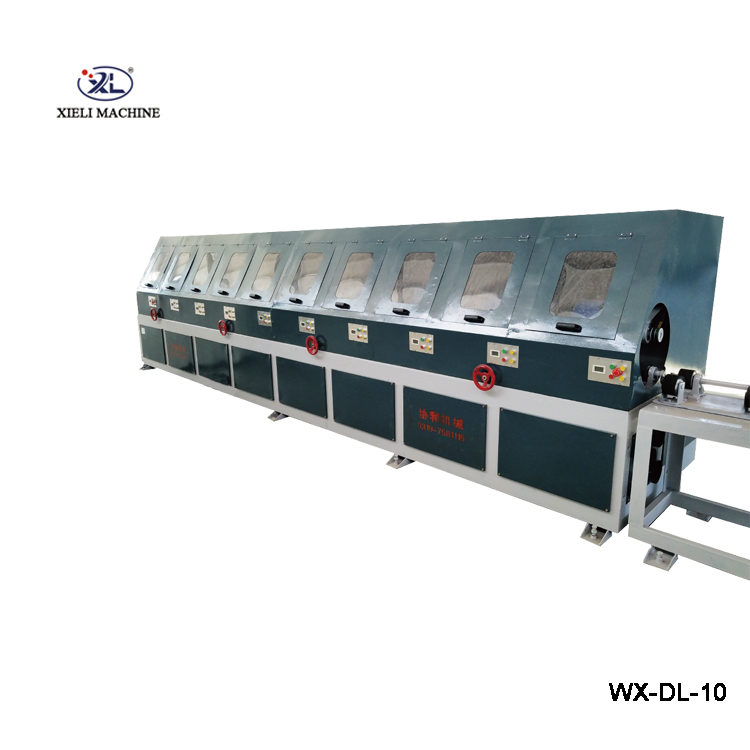

cheap centerless tube polishing machine

Versatility Across Industries

Another compelling aspect of centerless tube polishing machines is their versatility. They are suitable for various industries that require tube polishing, including automotive, aviation, furniture, and more. Different materials can be polished, ranging from stainless steel and aluminum to brass. This flexibility ensures that companies can adapt their manufacturing processes to meet diverse customer demands and product specifications with minimal adjustments.

Quality Improvement

While cost is a significant factor, it’s crucial that the quality of the finish is not overlooked. Cheap centerless tube polishing machines are designed to deliver consistent results through precision engineering and durable components. A well-polished tube not only looks better but also performs better. For instance, smooth surfaces can reduce friction, improve corrosion resistance, and enhance the overall lifespan of the product. Investing in a reliable yet affordable polishing machine ensures that quality is maintained across batches.

Reducing Labor Costs

By automating the polishing process, companies can significantly reduce labor costs. Centerless tube polishing machines require less manual intervention compared to traditional polishing methods. This not only frees up skilled labor for more complex tasks but also helps in optimizing workforce management. Employees can be shifted from routine polishing jobs to areas requiring more technical expertise, thus improving overall operations.

Conclusion

In conclusion, cheap centerless tube polishing machines offer a compelling solution for businesses looking to enhance their manufacturing processes without incurring substantial costs. Their effectiveness in boosting productivity, maintaining quality, and providing versatility across different materials and industries makes them an excellent choice for manufacturers aiming to stay competitive. By investing in these machines, companies can not only improve their finishing capabilities but also support their overall operational goals in an ever-evolving market. The benefits of adopting these machines extend far beyond initial cost savings, positioning businesses for long-term success and sustainability in their respective industries.