Finding Affordable Centerless Grinder Suppliers

In the realm of manufacturing and precision engineering, centerless grinding has emerged as a pivotal process. This technique is employed to achieve a high level of accuracy in the diameters of cylindrical components. However, succeeding in this area often hinges on selecting the right equipment and suppliers. For many businesses, especially small to medium-sized enterprises, budget constraints are a critical consideration. This article explores how to find affordable centerless grinder suppliers without compromising on quality.

Understanding Centerless Grinding

Before diving into supplier options, it's essential to understand what centerless grinding entails. Unlike traditional grinding methods that require the workpiece to be held between centers, centerless grinding allows for the workpiece to be supported only by the grinding wheel and the regulating wheel. This unique setup increases productivity and supports the efficient processing of long or cylindrical parts.

The Importance of Quality

While cost is a significant factor, it should not overshadow the importance of quality. A centerless grinder that fails to meet necessary specifications can lead to subpar products and increased operational costs due to rework or machine downtime. Thus, when exploring suppliers, it’s crucial to balance affordability with reliability.

Researching Suppliers

1. Online Marketplaces Websites such as Alibaba, Made-in-China, and Global Sources can provide an expansive list of suppliers. These platforms often have user reviews and ratings, which can help gauge the reliability of suppliers. Prioritize suppliers with positive feedback on their equipment’s performance and customer service.

2. Industry Forums and Trade Shows Engaging with industry-specific forums and attending trade shows can connect you with reputable suppliers. Here, you can gain firsthand insights into the machines’ operation and quality, as well as negotiate directly with suppliers for better pricing.

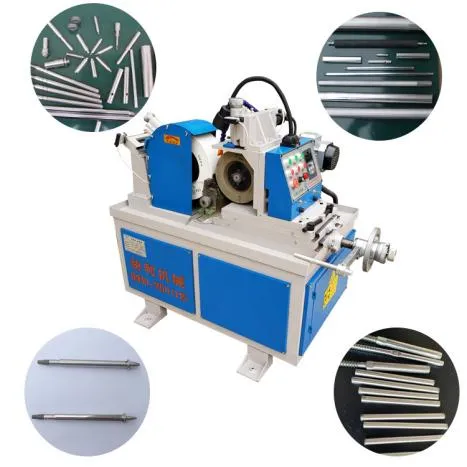

cheap centerless grinder suppliers

3. Local Manufacturers Don’t overlook local suppliers, which can often provide competitive pricing and the added benefit of easier communication and support. Visiting local manufacturers can also give you the opportunity to inspect the machines and discuss technical specifications in person.

4. Refurbished Equipment For companies looking for cost-effective solutions, considering refurbished centerless grinders can be a game-changer. Numerous suppliers specialize in refurbishing older models, ensuring they meet current standards of quality and efficiency at a fraction of the cost of new machines.

Negotiating Prices

When you identify potential suppliers, do not hesitate to negotiate prices. Many suppliers are open to discussions on bulk purchases or trial periods, which can lead to substantial savings. Building a relationship with your supplier can be beneficial, as they may offer discounts or flexible payment terms for loyal customers.

Evaluating After-Sales Support

In addition to initial costs, evaluate the after-sales support the supplier offers. Reliable customer service can make a significant difference, especially if issues arise post-purchase. Understanding warranty conditions, the availability of spare parts, and maintenance services can help ensure your production line remains operational.

Conclusion

Finding affordable centerless grinder suppliers is a balancing act between cost and quality. By researching various avenues, including online marketplaces, local manufacturers, and refurbished options, businesses can discover suppliers that meet their budgetary constraints. However, it is crucial to prioritize quality and after-sales support to maintain a competitive edge in the market. With the right approach, companies can successfully source centerless grinders that not only fit their financial requirements but also enhance their production capabilities.