Centerless Valve Grinder A Comprehensive Overview for Prospective Buyers

In the world of precision machining, centerless valve grinders play a crucial role in the manufacturing and refurbishment of valve components. These machines are designed to grind the outer surfaces of valves without the need for a central support, allowing for higher productivity and accuracy. For manufacturers and companies looking to invest in a centerless valve grinder, understanding the features, benefits, and key considerations is essential.

What is a Centerless Valve Grinder?

A centerless valve grinder is a specialized machine used to precisely grind the outer diameter of valve components. Unlike traditional grinding techniques, centerless grinding employs a unique system that relies on two rotating wheels a grinding wheel and a regulating wheel. This design allows for continuous workpiece rotation and support, resulting in a higher throughput and consistent surface finish. The versatility of these grinders makes them ideal for processing a variety of valve types, including automotive, industrial, and aerospace valves.

Key Features to Look For

When considering a centerless valve grinder for sale, there are several key features that potential buyers should evaluate

1. Grinding Capacity Assess the maximum diameter and length of the valves the machine can accommodate. Different applications may require different sizes, so it’s essential to choose a grinder that matches your needs.

2. Precision Control Look for grinders that offer adjustable settings for speed, feed rate, and grinding pressure. Fine control enables custom grinding operations, for varying materials, leading to improved finish quality.

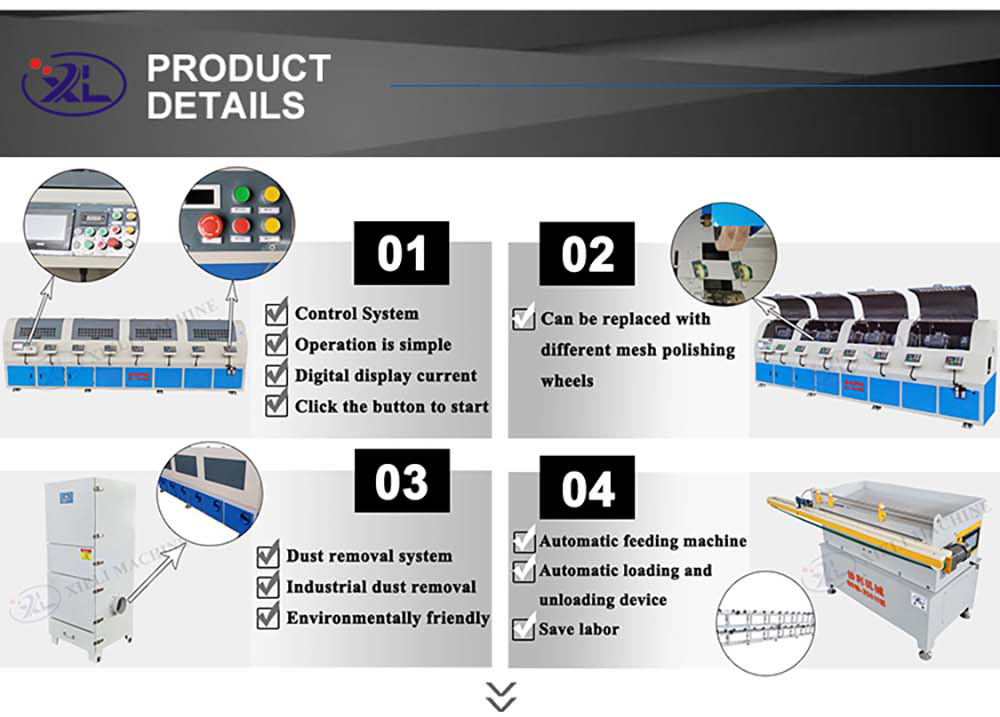

3. Automation Features Many modern centerless grinders come equipped with CNC (Computer Numerical Control) capabilities, allowing for automated adjustments and increased repeatability. This feature can significantly enhance productivity and minimize human error.

centerless valve grinder for sale manufacturer

4. Durability and Build Quality Machines made from high-grade materials and with robust designs typically offer longevity and reliable performance. Look for grinders with a reputation for durability, which can lead to lower maintenance costs over time.

5. Manufacturer Support Research the manufacturer’s reputation for customer service and support. Reliable after-sales support can help address any issues that may arise during operation and extend the life of the equipment.

Benefits of Using a Centerless Valve Grinder

Investing in a centerless valve grinder can provide numerous advantages for manufacturers

- Increased Efficiency The ability to grind without center support speeds up the machining process significantly, allowing for higher production rates.

- Improved Surface Finish The precision grinding process delivers superior surface finishes, essential for the performance and longevity of valves.

- Flexibility in Operations Centerless grinders can be adapted to different types of valves and materials, offering versatility that is crucial in a competitive market.

Conclusion

Centerless valve grinders are essential tools for companies looking to enhance their machining capabilities in valve production and refurbishment. By considering the key features and benefits outlined above, manufacturers can make informed decisions when selecting the right equipment for their operations. As technology continues to evolve, investing in advanced centerless grinding machines can pave the way for increased productivity and superior product quality in the valve manufacturing industry. Whether you are looking to purchase a new machine or upgrade your existing setup, understanding these factors will help you find the ideal centerless valve grinder for your needs.