Centerless Tube Grinding Machine Revolutionizing Precision in Manufacturing

In the world of manufacturing, precision is paramount. For industries requiring the highest standards of accuracy and efficiency, the introduction of centerless tube grinding machines has been a game-changer. This advanced technology not only streamlines the production process but also ensures the quality of the finished products.

Centerless tube grinding machines are designed to perform grinding operations without the need for a spindle or fixture, thereby enhancing productivity. The process begins with a loading mechanism that feeds the tube through the grinding wheel without requiring additional support. This unique method allows multiple tubes to be processed simultaneously, significantly increasing throughput and efficiency.

The primary advantage of centerless grinding is its ability to maintain tight tolerances. Traditional grinding methods can introduce errors due to part handling and setup changes. In contrast, the centerless process ensures that the part remains in contact with the grinding wheel at all times, reducing the likelihood of inaccuracies. This is particularly important in industries such as automotive, aerospace, and medical device manufacturing, where even minute precision can have substantial implications.

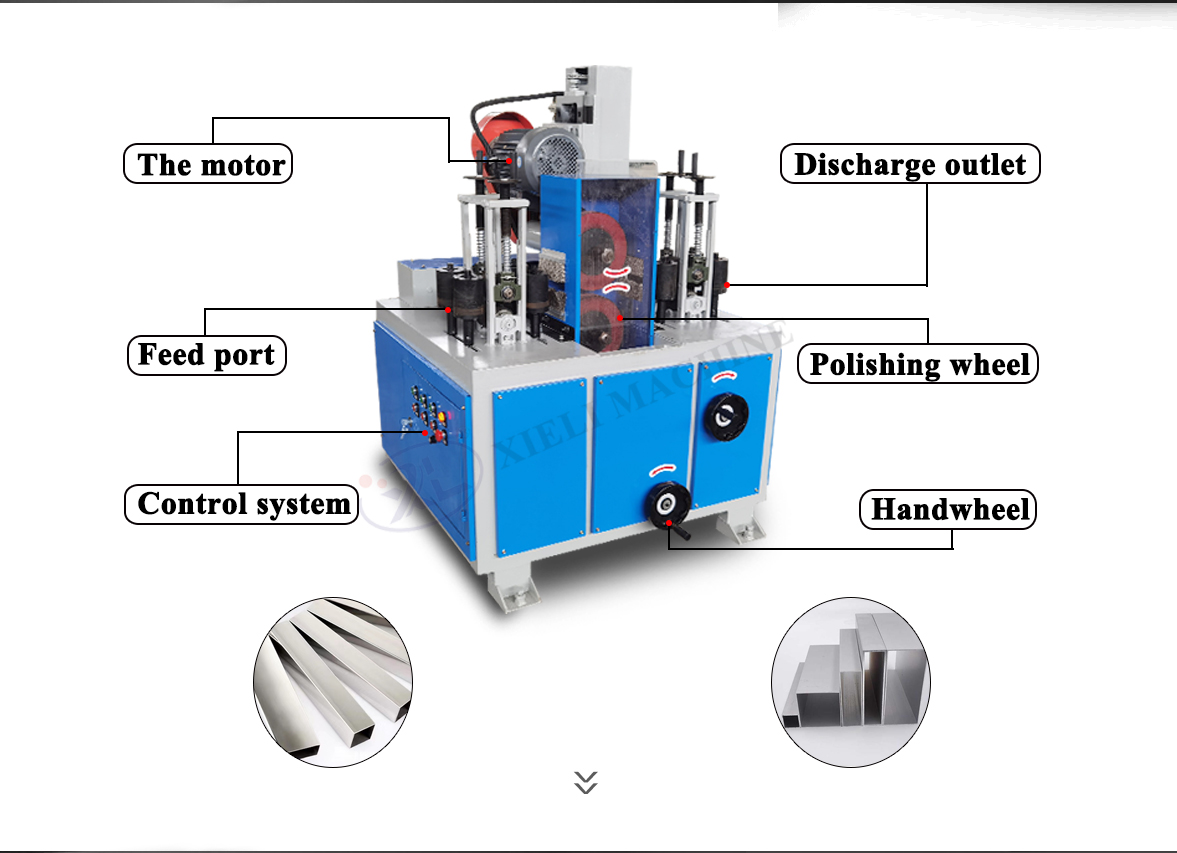

One of the main components of a centerless tube grinding machine is the grinding wheel itself. These wheels are specially designed to accommodate various tube sizes and materials, allowing for versatility in manufacturing. The use of high-grade abrasives ensures longevity and effectiveness in grinding operations. Furthermore, machines can be customized to meet specific requirements, catering to the unique demands of different manufacturing processes.

Another significant feature of centerless tube grinding machines is their automation capabilities. Many modern models are equipped with advanced control systems that enable operators to input precise specifications for the grinding process. This automation reduces the risk of human error and allows for consistent output quality. In addition, advanced monitoring systems can track and collect data during production, offering insights that can lead to further optimization of the grinding process.

centerless tube grinding machine company

Moreover, centerless grinding is an environmentally friendly option compared to traditional methods. The continuous feed eliminates waste generated from changing fixtures and setups, and the efficient use of resources minimizes energy consumption. With growing emphasis on sustainability, manufacturers are increasingly drawn to technologies that align with eco-friendly practices.

The application of centerless tube grinding is widespread across various sectors. In the automotive industry, for example, it is used to grind components such as valves, axles, and shafts, all of which require high precision to ensure optimal performance. In the aerospace sector, where safety and reliability are crucial, centerless grinding provides the accuracy needed for critical components. Similarly, the medical device industry relies on precise tube grinding for instruments and implants that meet stringent safety standards.

Moreover, the ease of maintenance associated with centerless tube grinding machines contributes to their appeal. Manufacturers can ensure minimal downtime by implementing regular maintenance checks, which helps to prolong the lifespan of the machine and maintain production efficiency. The user-friendly design also allows operators to quickly learn and adapt to the machine, reducing the training required for new employees.

As industries continue to evolve and demand higher levels of precision, the significance of centerless tube grinding machines will only increase. These machines exemplify the marriage of technology, efficiency, and quality, making them indispensable tools in modern manufacturing.

In conclusion, centerless tube grinding machines have transformed the manufacturing landscape by enhancing productivity, maintaining precision, and promoting sustainability. As more companies recognize the advantages of this technology, we can anticipate its greater adoption, ensuring that industries continue to thrive in a competitive global market. With ongoing advances in automation and machine design, the future of centerless grinding looks promising, paving the way for even more innovative manufacturing solutions.