Centerless Grinding on Surface Grinder A Comprehensive Overview

Centerless grinding is a vital manufacturing process used to create precision components with tight tolerance specifications, which makes it a popular choice in various industries, including automotive, aerospace, and medical device manufacturing. Unlike conventional grinding processes, centerless grinding eliminates the need for a workholding fixture, allowing for continuous production and improved efficiency. When discussing centerless grinding within the context of a surface grinder, it’s essential to understand both the applications and the pricing dynamic that influences this process.

Understanding Centerless Grinding

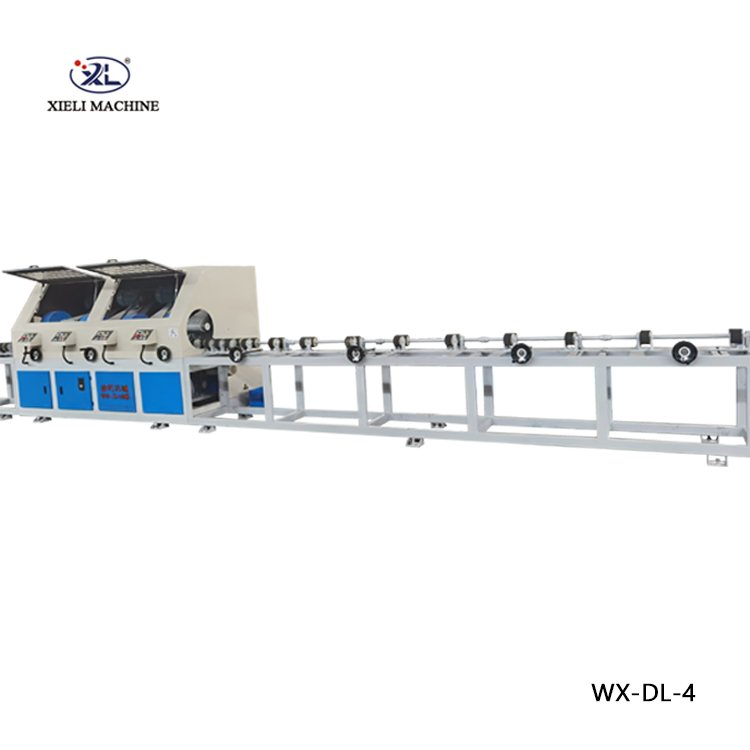

Centerless grinding involves three main components the grinding wheel, the regulating wheel, and the workpiece. The workpiece is not held in place between centers. Instead, it is supported on the work rest blade and held in place by the regulating wheel's pressure. This unique configuration allows for high-speed operations, enabling manufacturers to produce large quantities of parts with exceptional accuracy.

There are distinct types of centerless grinding processes through-feed, in-feed, and end-feed grinding. Each method caters to different shapes and sizes of workpieces. Through-feed grinding is typically used for cylindrical parts, while in-feed and end-feed methods accommodate different geometries, including complex shapes that require precise cut-off features.

Applications and Advantages

The advantages of centerless grinding are numerous. It is particularly advantageous for producing long, cylindrical parts with high roundness and low surface roughness. Additionally, the elimination of fixtures reduces setup times and costs, significantly enhancing productivity. Centerless grinding is also capable of processing larger volumes of parts in a time-efficient manner, which is advantageous for manufacturers aiming to meet high demand with tight production schedules.

Industries utilizing centerless grinding often require components such as shafts, pins, rollers, and other precision parts. The application of this process spans across various sectors, highlighting its versatility. For instance, in the automotive industry, centerless grinding is used to manufacture crankshafts, camshafts, and pins, whereas, in the aerospace sector, it is essential for producing components like turbine blades and other critical engine parts.

Pricing Structure of Centerless Grinding Services

centerless grinding on surface grinder pricelist

The pricing for centerless grinding services can vary widely based on several factors, including the complexity of the component, the type of grinding required, material specifications, and the volume of production. Typically, the pricing model can be broken down into several key components

1. Material Costs The type of material being processed can significantly affect pricing. Exotic metals and hardened materials generally incur higher costs due to the increased wear on grinding wheels and machinery.

2. Setup and Labor Costs The time and resources necessary for setting up the grinding machine and the labor involved in operating it can influence the price. More intricate setups or specialized labor will lead to higher overall costs.

3. Volume of Production Often, a higher volume of production reduces the per-unit cost. Manufacturers may offer discounts for bulk orders, as the efficiency of running a machine for an extended period lowers the overall operational costs.

4. Complexity of the Job Parts requiring intricate geometries or tighter tolerances often demand more advanced machinery and skilled labor, which can drive up costs.

5. Finish Requirement The desired surface finish plays a crucial role in determining pricing. Parts that require finer finishes or specific coatings will typically be more expensive due to additional processing requirements.

Conclusion

Centerless grinding on a surface grinder represents a cutting-edge solution for achieving precision in manufacturing. Understanding the intricacies of this process, including its advantages, applications, and pricing dynamics, enables companies to make informed decisions regarding their machining needs. As technology evolves, the capabilities of centerless grinding are likely to expand, further solidifying its role in the manufacturing landscape. For businesses seeking to optimize their production efficiency and maintain high quality, investing in centerless grinding services is a strategic choice that can yield significant benefits in the long run.