Understanding Centerless Grinding Machine Parts Suppliers

In the world of precision machining, centerless grinding plays a pivotal role in the manufacturing process. This technique is widely used for producing cylindrical parts with high accuracy and excellent surface finishes, making it essential for various industries, including automotive, aerospace, and medical equipment manufacturing. At the heart of this process lies the centerless grinding machine, which relies on several key components. Consequently, understanding the suppliers of these machine parts is crucial for manufacturers looking to optimize their production capabilities.

What is Centerless Grinding?

Centerless grinding is a method of removing material from a workpiece by using a rotating grinding wheel. Unlike traditional grinding methods, which require the workpiece to be held between centers or in a chuck, centerless grinding allows the workpiece to be supported by a resting plate and the grinding wheel. This unique setup offers several advantages, including the ability to grind multiple parts simultaneously and achieve high levels of precision.

The process involves three primary components the grinding wheel, the regulating wheel, and the workpiece. The grinding wheel removes material, while the regulating wheel controls the speed and position of the workpiece. Additionally, the infeed mechanism facilitates the movement of the workpiece through the grinding area.

Importance of Quality Machine Parts

The effectiveness of centerless grinding largely depends on the quality and performance of its components. The grinding wheels must be made from high-quality abrasives to ensure efficient material removal while maintaining the desired surface finish. The regulating wheel also plays a crucial role in controlling the part's geometry during the grinding process. Low-quality parts can lead to subpar performance, increased wear and tear, and ultimately affect the product's overall quality.

Hence, partnering with reputable suppliers of centerless grinding machine parts is essential for manufacturers. These suppliers provide the necessary components that meet industry standards and performance requirements, contributing to the overall efficiency and reliability of the grinding operations.

Key Considerations When Choosing Suppliers

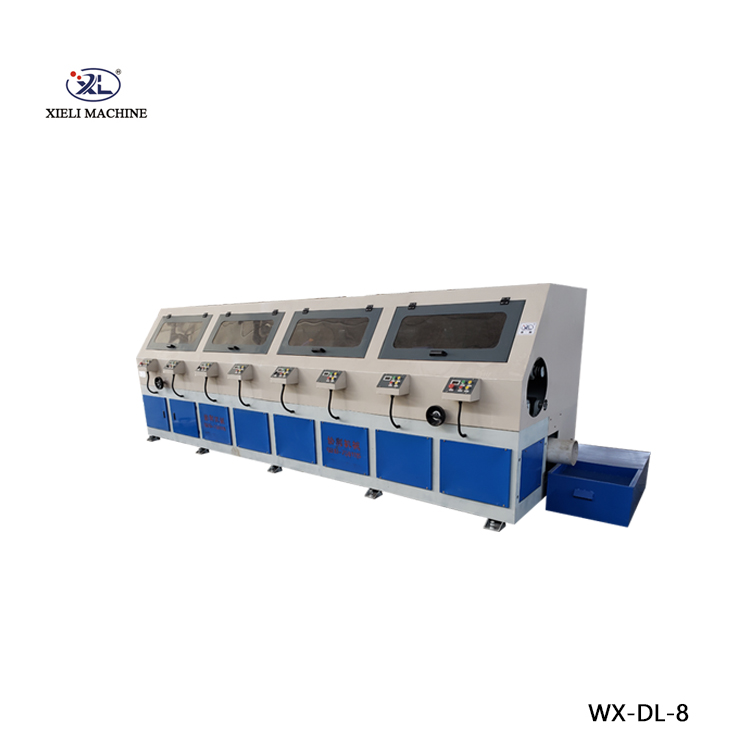

centerless grinding machine parts suppliers

When searching for centerless grinding machine parts suppliers, manufacturers should take several factors into account

1. Quality of Parts The primary consideration is the quality of the machine parts being offered. Suppliers should provide detailed specifications, test results, and compliance certifications that demonstrate their components can withstand the rigors of manufacturing processes.

2. Product Range It's beneficial to choose suppliers that offer a wide range of products. This can include various types of grinding wheels, regulating wheels, and other components crucial for centerless grinding. A comprehensive supplier can meet diverse needs and provide solutions for custom applications.

3. Service and Support Suppliers that offer excellent customer service and technical support can significantly enhance a manufacturer's capabilities. In case of issues, having immediate access to knowledgeable support personnel can save time and reduce downtime in production.

4. Delivery Times Quick and reliable delivery times are essential for manufacturers. Delays in receiving parts can lead to project holdups and lost revenue, making it critical to select suppliers known for their timely delivery.

5. Cost-Effectiveness While quality should not be compromised, it is equally important to consider the cost of parts. A supplier that offers fair pricing without sacrificing quality is more likely to be a valuable long-term partner.

The Future of Centerless Grinding Components

As technology advances, the demand for higher precision and speed in manufacturing will continue to grow. Suppliers of centerless grinding machine parts will need to adapt by innovating and developing new materials and components that can withstand higher levels of stress and deliver better performance. Additionally, as industries shift towards automation and Industry 4.0, suppliers that embrace technological advancements in their product offerings will stand out in the market.

In conclusion, centerless grinding is vital in various manufacturing sectors, underscoring the importance of reliable suppliers for machine parts. By prioritizing quality, support, and technological adaptability, manufacturers can enhance their production processes and ensure they remain competitive in an ever-evolving industry landscape.